An electronic product comprises components and, nowadays, some software as well. But components still form a major part of the product’s cost in most cases. What if the components fail early and thus adversely affect the reputation of a brand? Not only will this bring a disrepute to the company, it may also affect their sales and their future. So, how do we ensure that this does not happen? Read on to find out.

The most important aspect of an electronic product is its components. A product’s success or failure depends on the components used in the product. Normally, components form roughly 75% of the product cost. But improperly selected components can destroy the product’s performance as well as damage the company’s reputation beyond recovery.

Most designers assume components are mainly electronic parts. Unfortunately, that is not true. A typical electronic product consists of three category of components;

- Basic electronic parts like resistors, capacitors, transistors, ICs, etc

- Commercial off-the-shelf (COTS) items like power supplies, display systems, keyboards, etc. These are electronic products which become part of the bigger product

- Custom designed parts (typically mechanical items) items like sheet-metal or plastic enclosures, cable harness, and printed circuit board assemblies (PCBAs). Typically, custom designed parts are specific to a product and are expensive as they have to be created through a fresh design.

Performance of a product depends on some key aspects like:

- Cost of the components

- Shape of the components (smaller parts need automated assembly and tend to have an expensive process)

- Leadtime of the part’s availability, that is, how much time the vendor will take to supply from the day purchase order is released. Longer the lead-time, larger the inventory companies have to maintain to keep the production line running

- Life of the part (basically how long the component is available before the product production is stopped)

- Quality of the COTS components and their availability

- Components handling and storage. Most ICs use plastic encapsulation and tend to absorb moisture if not properly stored. The components have to be typically stored in a dry environment (in specially designed racks)

- Similarly, most integrated circuits are sensitive to static electricity. These components have to be stored in static-free area to protect them from getting damaged

- Equivalent components for replacement (typically applicable for passive resistors and capacitors, and active components like transistors and some logic ICs)

- Fake parts that are sold as original part but will not work at all

- Pulled out parts that are pulled out of waste PCBAs and cleaned up and sold as new parts

Why components are critical

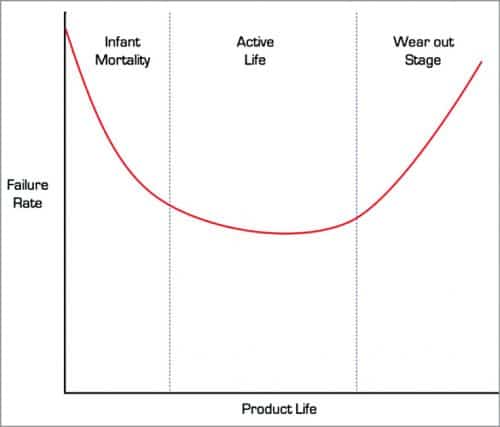

Right component selection contributes to more than 60% to a product’s performance and reliability. Most electronics parts fail in the early stage of the product’s use. Fig. 1 which shows the reliability or failure rate curve for a typical electronic product.

When you have a component quality problem, which could be an electronics part, or custom OEM part (like power supply unit) and mechanical item failure in the manufacturing line, it falls in the zone of infant mortality. In this infant mortality failure, the losses are minimal as the product has not left the manufacturing plant. If a product fails in the customer’s location, it becomes a warranty claim or service call depending on the product’s age. If the failure is within the warranty period company’s reputation takes a beating due to the perception of bad or low quality.

Most infant mortality cases can be traced back to components, while failure could also have been due to bad design. But chances of a bad design escaping is very minimal. As you can see in Fig. 1, product failure is minimal when the product is in its active life post infant mortality stage. This performance is directly due to choice of right components. Most important aspect is that good components ensure reliable product, and that is in the hands of the designers and the supply chain team.

It is seen that engineers pay little attention to the components. They believe the data sheet 100% and think the data sheet is the golden rule. Most data given in the data sheet are statistically arrived as component tolerances and will be varying component to component. This means designers need to know how to use these limits and arrive at a reliable design. This is especially true for the passive components.

If the design is measuring voltage or current, the tolerance of the parts can kill the design if done wrongly. This article does not delve into design aspect of components from a tolerance and rating perspective in the article, which will be taken up at a later date.

Some examples

To explain why component selection is very critical, here are some examples.

When we were designing a DSL line card, we had failures when high-voltage test was done. Since the DSL lines run for 3-4km underground as well as overhead, injecting 600V AC is done to ensure, if the DSL line comes in contact, it will be protected. In the initial production in lab the design worked very well. So, we went for pilot manufacturing for certification.

But when we tested the line cards, all of them failed one by one. On comparing the board that passed with the failed one there was no apparent design change. Finally, we started looking at the part which had failed. We found that there was shunt resistance which was provided to bleed any high voltage in design, which had failed consistently in the newly made board.

This forced us to look at the components used. We realised that this shunt resistance, which should have been a carbon resistor, had been replaced with a metal-film resistor. A metal-film resistor is accurate to 1% but tends to evaporate under application of high voltage. How did the component gets changed?

Well, the guy purchasing the components saw there was only one carbon resistor with 5% tolerance and rest were 1% metal-film resistors. Thinking 1% tolerance would be better than 5%, he substituted the carbon resistor with metal-film, leading to the failure!

Second example is pretty recent. We had designed an IoT enabled consumer equipment and the OEM wanted us to deliver 100 units for marketing purpose. The purchase team, due to lack of time, bought a particular IC (single-phase metering device) from a local vendor. But the device was a fake, except the number on the part. It was a dud device. We lost money and time, and eventually the customer too!

One common problem I have seen, when you buy parts in tray packing, there are high chances of the parts absorbing moisture when the tray is not stored properly. And the packaging can crack during reflow due to the expansion because of moisture absorbed by the packaging. This typically happens with plastic packaging.

What needs to be factored when selecting components

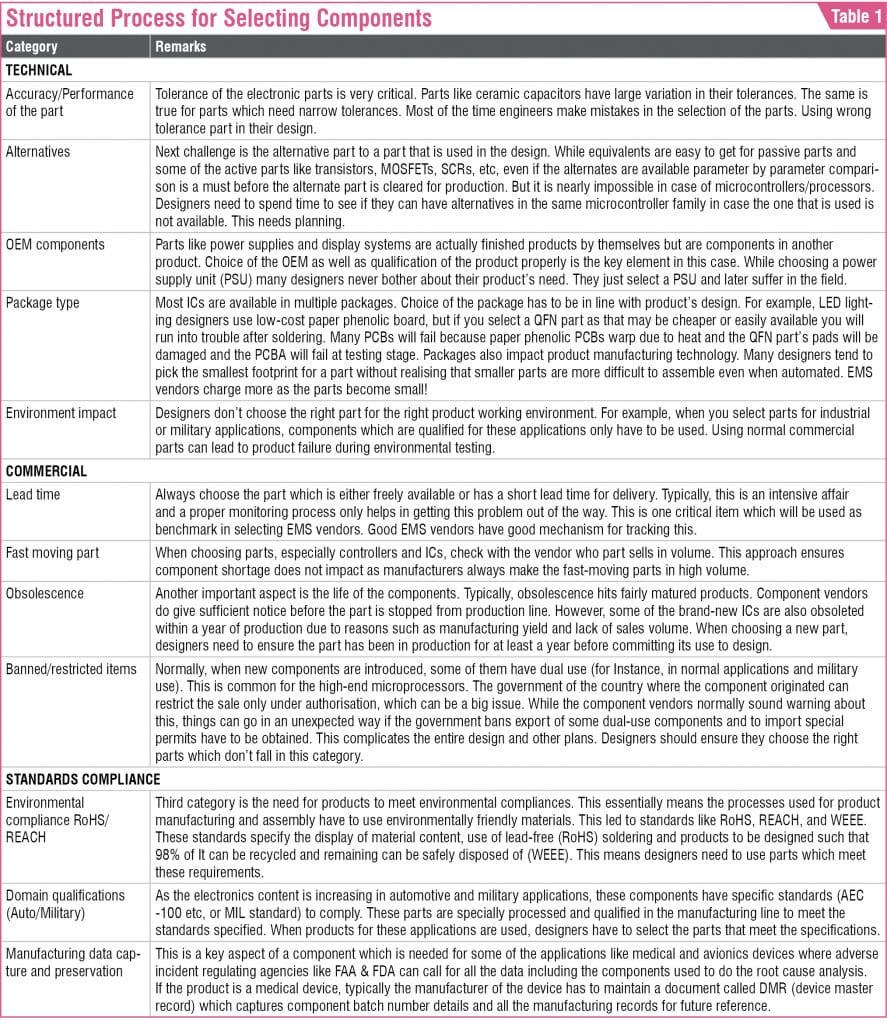

While component selection is a big topic and most leading EMS vendors have a separate department as part of their supply chain division for component engineering, there is a structured process for the same. Essential aspects that need to be factored can be classified into three groups that are presented here in a simple table format.

Points to be kept in mind

Component selection is the most important aspect that decides the performance of a product. Here are the critical things that designers have to look at while selecting the products:

- When signing for contract manufacturing, check with the EMS vendor whether they can support you with component engineering (a topic to be covered sometime later). This reduces most of the component issues.

- Check with the EMS partner whether they can share their existing stock along with part number? (They won’t share the cost anyway!) This helps in ensuring easy availability and also sometimes lower cost.

- Software tools are the most often neglected aspect when microcontrollers are selected. While most microcontrollers have the support of open source tools, their ability to develop compact code can be a challenge. Additionally, when the designers are developing a safety-critical product, the tools used should have been certified and should have been subjected to a third-party verification and validation. (Third-party V&V means the tool should have been verified by a party which is not involved in the development of the tool.) Knowing this requirement up front will help the designers to avoid costly time delay.

- 4With microcontroller based devices choose a device which has higher memory size for the same footprint. This helps in offering upgrade or field support without any hardware change.

- Another important aspect is programming of devices in the manufacturing line. While there are multiple options available, designers need to check with the EMS vendor what facility they have to support high-volume programming of the devices.

- 6. One more important aspect is the availability of JTAG test libraries for testing VLSI devices like microcontrollers. Test libraries make the PCBA testing easy and accurate and are an important checklist item.

S.A. Srinivasa Moorthy is a director of D4X Technologies Private Limited