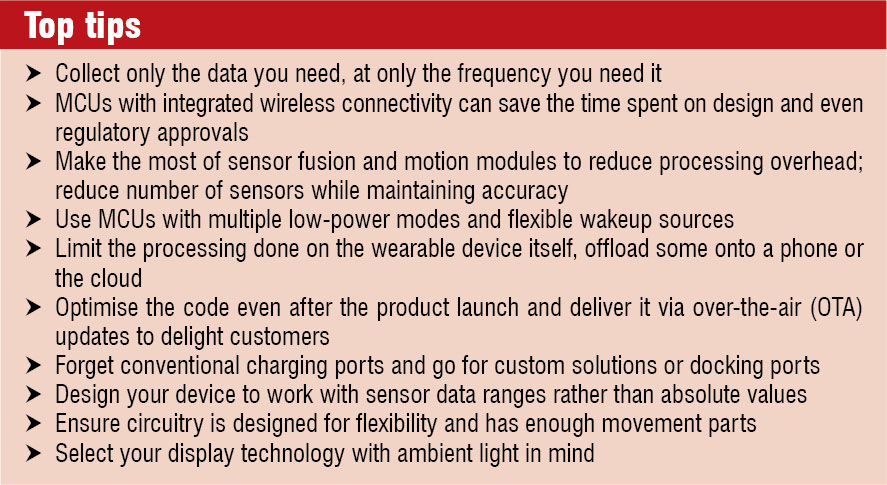

“The advice I would give is to use the basic principles of a good design; collect only the data that you really need and only with the frequency you need it. Make sure to do as little processing as possible and communicate data as late and as infrequently as possible,” Singh adds.

Data processing needs to be moved to the gateway; in the case of most wearables, this gateway is the smartphone. This is where the right hardware-software co-design aspect becomes critical.

Wearable devices can include many combinations of biometric and physiological sensors, depending upon the data that these are designed to collect. These data can include distance walked, calories burned, heart rate, temperature, blood-oxygen level, sleep quality, pressure and others.

“Specifics of what is being measured drive the selection of MCUs, signal-conditioning components and connectivity chips that are used in a wearable device. Some key requirements for a wearable device are low power, connectivity and sensor-data processing capability,” explains Smith.

Wireless connectivity allows wearable devices to interface with smartphones, tablets, PCs and other intelligent devices. Agency-certified, low-power Bluetooth, Bluetooth Smart and Wi-Fi modules can satisfy the requirement to get to market quickly, and can save significant time in RF design and regulatory approvals.

The demand for higher-accuracy location processing in low-cost wearable devices is increasing. These high-accuracy wearables typically need to receive inputs from multiple sensors such as accelerometers, magnetometers, gyroscopes, light sensors and pressure sensors.

Traditionally, these high-accuracy designs would need complex MCUs and correspondingly long software-development times. The use of sensor-fusion chips, known as sensor hubs or motion modules, can significantly reduce MCU size and software development time in high-accuracy location-tracking designs.

Let us take a global positioning system (GPS) for example. GPS requires continuous communication to at least three satellites at the rate of 50 bits per second. Antennae used for this communication need to be powered. Algorithms and computations needed to calculate the position after getting information like location, speed and orbital trajectory also take up power. This is why health trackers take up a lot of battery when the GPS module is activated.

In the given examples, only Microsoft Band offers a built-in GPS module, and the battery drains 50 per cent faster if you turn on the GPS.

One observation made at CES 2015 was that, sports-tracking wearables from 2013-14 are getting more specialised to take on competition from technology giants like Apple and Samsung. This is with good reason, too.

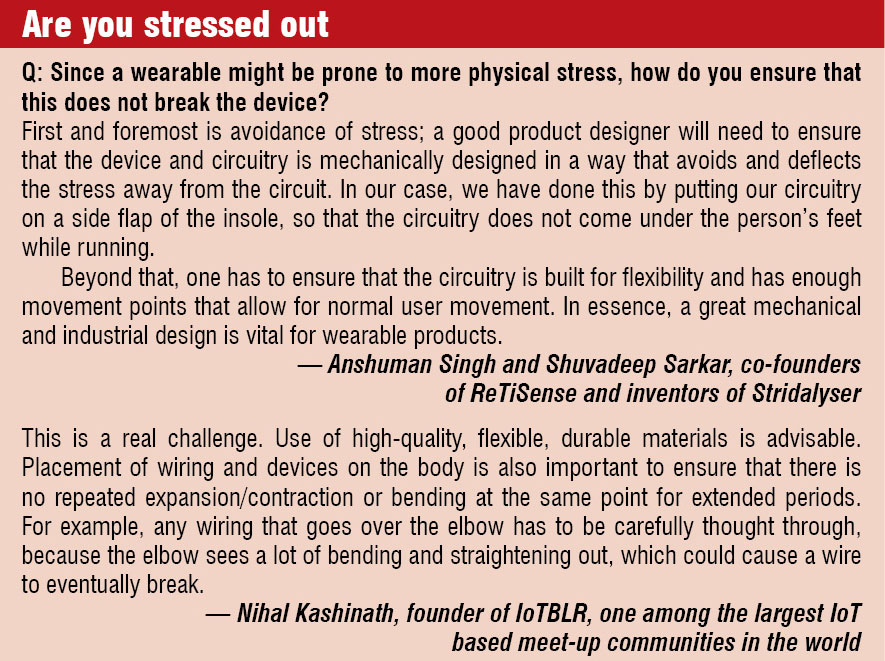

“An important characteristic that influences the design of any wearable is that it is dedicated for a specific function. For instance, our wearable device is designed to measure and analyse the running form and gait of the user but not the number of calories, steps or distance like other fitness wearables,” explain Anshuman Singh and Shuvadeep Sarkar, co-founders of ReTiSense and inventors of Stridalyser.

Singh explains that this is what influenced the design decisions, leading to the placement of sensors inside the shoe and connecting with the lower part of the feet. It is essential to ensure that it collects the right kind of data, which, in turn, enables the device to deliver accurate information to the user.

Nihal Kashinath, founder of the Internet of Things (IoT), Bangalore community, explains, “Unless you are dealing with health or safety-related devices, design your device and software to work effectively with sensor data ranges rather than absolute values. It will reduce the need to work with data from multiple sensors that only serve to improve accuracy.”

Form factor and safety rules

“In wearables, engineers struggle to fit everything into a tiny package. In normal portable devices, size is not a constraint. But in wearables, custom batteries have to be designed that will go along with the gadget, while ensuring these are capable of powering the device for a long time,” says Sanjeev.

“Also, the material used for the wearable should be carefully selected. Since it is in constant contact with the skin of the user, choosing any material for the device could result in catastrophic situations where it might even trigger skin allergies,” he adds.

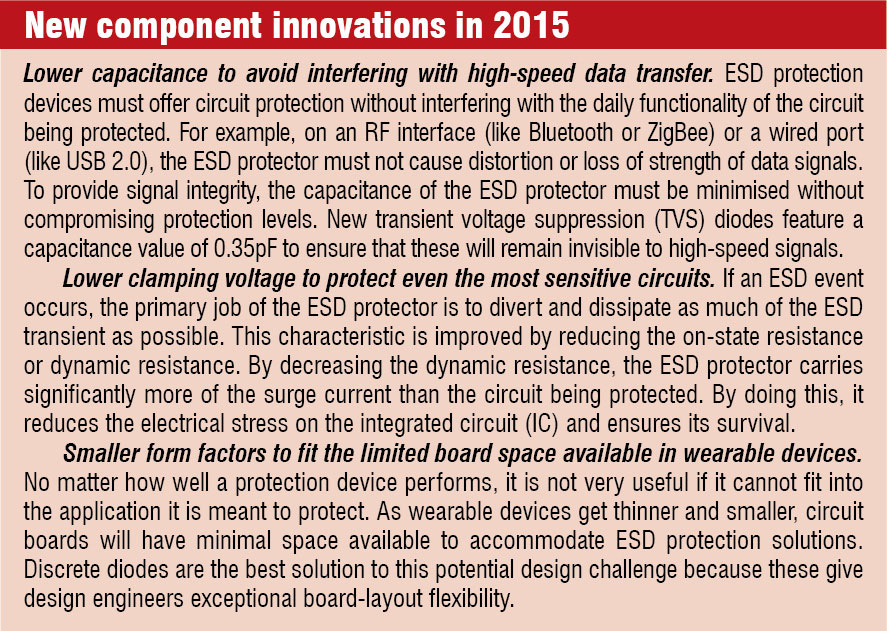

Wearable technology presents an interesting challenge to circuit designers. Why? Think about how these devices are designed to get close and personal with the consumer. Because these are meant to be worn on the skin, there is significant risk of exposure to user-generated static electricity. For instance, Jawbone wristband uses a Littlefuse polymeric positive temperature coefficient (PPTC) device resettable fuse.

Unfortunately, simple human touch can generate transient electrostatic discharge (ESD). Without proper protection, any sensor circuits, battery-charging interfaces, buttons or data I/Os could provide a path for ESD to enter the wearable device and cause irreparable damage.