Product display screens are output devices that are used to represent output data or information. These are used in almost all electronic devices, such as mobile phones, televisions, refrigerators and computers. A few years ago, cathode ray tubes (CRTs) were used as displays in televisions. Researchers explored this field and, with the help of different technologies, many other types of displays were invented; for instance, light emitting diodes (LEDs), liquid crystal displays (LCDs) and now quantum dot light emitting diodes (QLEDs) and indium gallium zinc oxygen (IGZO). The displays have become bigger as well as thinner because of these technologies.

At present, televisions come with full high-definition (HD) resolution and a thickness of approximately 25mm along with Wi-Fi support, voice recognition feature, 3D sound system and other attractive features. This article focuses on the latest QLED and IGZO display technologies. These technologies are responsible for bringing in a revolution in television and other displays such as those in mobile phones. Quantum dots are the key elements of these technologies. Hence, we need to analyse the quantum dot and its effect first before discussing QLED.

Introduction to quantum dot

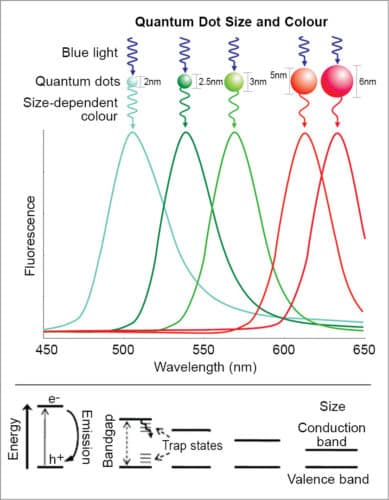

Quantum dots are tiny semiconductor neon-scale crystals, about 2nm to 10nm in size. These can be precisely controlled with respect to size, energy level and emission wavelength for various applications like energy-efficient displays, solar cells and biological medical research. According to Quantum Physics, quantum dots emit colour according to the size of the quantum. Bigger the quantum dot, larger the wavelength. Fig. 1 shows the graph detailing wavelength versus fluorescence, which depends on the size of the quantum dot and the energy gap of the material.

Quantum dots can be created using different methods, but generally these are made by chemical reactions in a solution. The chemical reaction is done over 200+°C temperature. Many different semiconductor material combinations such as cadmium selenide (CdSe), cadmium sulphide (CdS), lead selenide (PbSe), lead sulphide (PbS), indium arsenide (InAs) and indium phosphide (InP) are used to make quantum dots. These absorb light and release energy in terms of different colours of light according to the band gap of the material, as shown in Fig. 1.

Quantum dots, till recently, were generally made of CdS or CdSe. These particles are hazardous to the environment, and during in-vitro degradation, Cd2+ ions may get discharged. Samsung uses cadmium-free quantum dot technology, and at present quantum dots use indium (Id). This technology can produce numerous colour combinations (approximately one billion) that provide better light efficiency.

In the third generation of quantum dot televisions, some particles (metal alloy core and metal alloy shell) have been changed. This technology has enabled far better visibility with peak brightness and colour accuracy. Further, it claims to give viewers a good visual experience.

Construction of an image

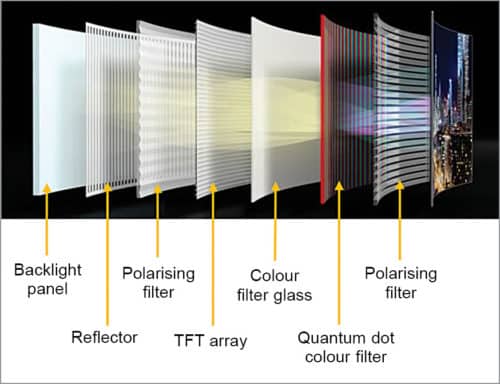

There are three basic colours— namely, red, green and blue— that are used to create a colour image. Consider quantum dot LEDs in which a thin layer of quantum dots is used in front of the backlight. In LCD televisions a liquid crystal layer is used to generate different colour spectrums. In QLED a layer of quantum dots is used. As shown in Fig. 2, six layers are used to construct a colour image. Here, functions of all the layers are given in brief.

The backlight unit illuminates the LED from the side or back of the display panel as QLEDs do not produce light by themselves. These need a special source of light to produce a visible image. OLEDs (organic LEDs) illuminate the LEDs by themselves and hence do not need any light source. Light produced by the backlight unit for QLEDs is passed to the reflector, which enhances the uniformity of the illuminance distribution on the target region of the image plane.

A polarising filter is used to change the settings of the image passed by the reflector so as to suppress the glare or blur the image. There are various types of polarisers used in display technology. The importance of a thin-film-transistor (TFT) array is to match the size with the quantum dot in the colour filter (in QLED) and carry out colour reproduction. It also handles how the pixels are displayed on the screen. In QLED, quantum dot colour filters coupled with a blue LED can produce billions of colours with peak brightness and better clarity.

There are two main key advantages of quantum dot materials. First, these resist moisture better and thus have a longer life period. Second, because of their higher resistance to moisture, these do not require an expensive vacuum evaporation process. Last, a polarising filter gives a final touch to the display to produce a crystal-clear image on the screen.

IGZO technology

IGZO is composite of indium (Id), gallium (Ga), zinc (Z) and oxygen (O). An IGZO-TFT is artificially produced and used in flat panel displays, which are made of transparent crystalline oxide semiconductors. This newly-invented IGZO-TFT enables LCD and OLED displays to achieve new levels of performance. Because of its attractive features, it is being used in ASUS notebooks, ultrabooks by Fujitsu and Razor Blade gaming laptops. Sharp mass produces it successfully. Low power consumption with high performance and high resolution are the key features of this technology.

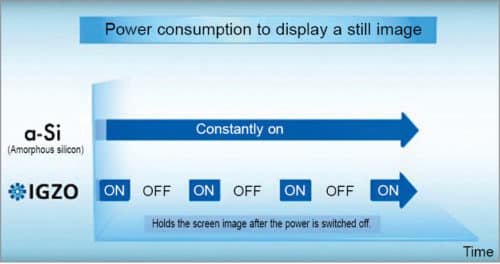

Low power consumption with high performance. A comparison between the conventional display method and new display methods is shown in Fig. 3. The former consumes more power because all pixels are driven continuously. IGZO consumes less power for backlighting or illumination in LED panel as compared to a-Si.

There are a number of TFTs arranged in a particular structure which will switch on or off depending on the contents being displayed on the screen. If the static image or video content is being displayed using IGZO that operates in pause mode (as it is in this case), there will be less leakage current and no flicker effect, which results in low power consumption. Thus, in IGZO-TFT technology, pixels maintain their charge throughout the cycle, which results in low power consumption and flicker-less high performance.

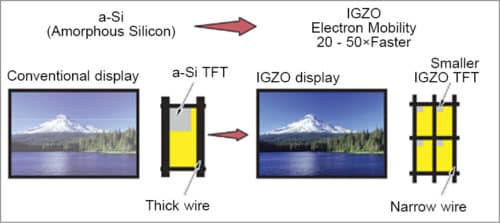

High resolution. In IGZO-TFT, as shown in Fig. 4, transistor size is small as compared to a-Si-TFT. Because of that, more numbers of pixels per area can be accommodated as compared to a-Si, which enables high resolution. On top of this, IGZO has a much lower leakage current and 20 to 50 times higher electron mobility as compared to a-Si, which results in fast response time or less processing delay.

To summarise, new display techniques using quantum dots and IGZO have changed the entire world of displays, especially in television domain. Their extraordinary features enable these to consume low power, perform better, give HD colour resolution, and televisions to be made thinner, lighter and more energy efficient.

Dr Arjav Bavarva is assistant professor at Department of Electronics & Communication, School of Engineering, RK University, Gujarat. His research interest lies is electronics, wireless communication and networking.

Tejas Bavarva is ME in VLSI and embedded system design. He is currently working as senior systems engineer at Infosys Ltd, Pune. His interests include electronics, VLSI and networking.

Good information

Thank you for your feedback.