In this article, we would be explaining all common types of sensors and its applications.

What is a Sensor?

A sensor is a device or a module which helps us to detect events or changes in its environment and share the information with other connected electronic devices.

The latest sensors, including those used in IoTs and wearables, are soon going to revolutionise electronics industry. Be it a silent heart attack detector that detects the protein level of a patient or a posture-correcting chair that alerts the occupant sitting in a wrong posture, both recently invented by Indian teenagers. Sensors have a vital role to play in electronic devices. The fact is that the application of sensors is ever-expanding along with the progress in science and technology.

As per industry reports, sensors are becoming the biggest and fastest growing markets, comparable with computers and communication devices markets. You find sensors in smartphones, automobiles, security systems and even everyday objects like coffee makers! Apart from consumer electronics, these are also an integral part of the Internet of Things (IoT), medical, nuclear, defence, aviation, robotics and artificial intelligence, agriculture, environment monitoring and deep-sea applications. Sensors can have various electrical output Voltage such as 5 volts, 10 volts -5 to +5 volts depends upon its applications and types.

The shift to smarter sensors

Basically, a sensor is an input device that receives and responds to a signal or stimulus. Nowadays some sensors come integrated with many sensing elements and read-out circuitry in a single silicon chip, providing high accuracy and multiple functions.

Manufacturers use both advanced technologies and methods for signal processing and conversion. Latest sensors have more features including user-friendliness, accessibility and flexibility. So there is a paradigm shift in the sensor industry with integration of new technologies to make sensors smarter and intelligent.

Ordinary sensors are still used in many applications. But innovation and advancement in microelectronics is taking sensor based technology to a completely new level. The functionality of ordinary sensors has expanded in many ways and these now provide a number of additional properties. The Latest Sensors are becoming more and more intelligent, providing higher accuracy, flexibility and easy integration into distributed systems.

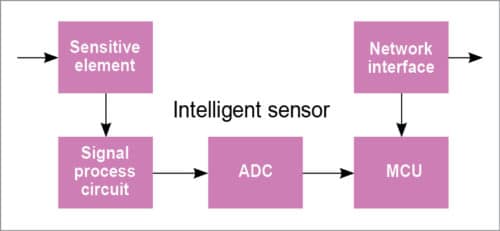

Intelligent sensors use standard bus or wireless network interfaces to communicate with one another or with microcontrollers (MCUs). The network interface makes data transmission easier while also expanding the system. Manufacturers can diagnose sensor faults and guide users to troubleshoot them remotely through the computer network.

An intelligent sensor may consist of a chain of analogue and digital blocks, each of which provides a specific function. Data processing and analogue-to-digital conversion (ADC) functionalities help improve sensor reliability and measurement accuracy. The typical structure of an intelligent sensor is shown in Fig. 1.

Common types of latest sensors

There are a wide variety of sensors depending on the technology (analogue/digital) and applications. This article covers some of the latest sensors including IoT sensors, pollution sensors, RFID sensors, image sensors, biometric sensors, printed sensors, and MEMS and NEMS sensors.

IoT sensors

IoT sensors include temperature sensors, proximity sensors, pressure sensors, RF sensors, pyroelectric IR sensors, water-quality sensors, chemical sensors, smoke sensors, gas sensors, liquid-level sensors, automobile sensors and medical sensors.

These latest sensors are connected to a computer network for monitoring and control purposes. Using sensors and the Internet, IoT systems have wide applications across industries with their unique flexibility in providing enhanced data collection, automation and operation.

The global market for IoT sensors reached $7.3 billion in 2015. It is expected to reach $47.8 billion in 2021 from nearly $10.6 billion in 2016, growing annually at 35 per cent during 2016-21. The Asia-Pacific market for IoT sensors is expected to grow from $3 billion in 2016 to $14 billion in 2021 at a CAGR of 36.1 per cent from 2016 through 2021.

Pollution sensors

Air pollution sensors are used to detect and monitor the presence of air pollution in the surrounding area. These can be used for both indoor and outdoor environments. Although there are various types of air pollution sensors, most of these sensors focus on five parameters: particulate matter, ozone, carbon monoxide, sulphur dioxide and nitrous oxide. These sensors are somewhat costly but are becoming more affordable for common use.

Sensors capable of detecting particulate matter with a diameter between 2.5 and 10µm (PM10) and a diameter less than 2.5µm (PM2.5) are available in the market. Fig. 2 shows a typical PM sensor popular among hobbyists and experimenters. Fig. 3 shows an easy-to-assemble PM2.5 sensor from Sharp Corporation with a detection time of ten seconds.

RFID sensors

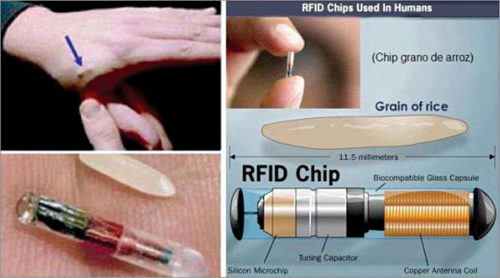

RFID chips (Fig. 4) as small as the size of rice grains can be inserted directly under the skin for use as ID cards. There is a trend to use RFID chips in many products including contactless banks cards and Oyster cards. There are also cases where chips are implanted in pets and cattle for monitoring.

Wearable sensors

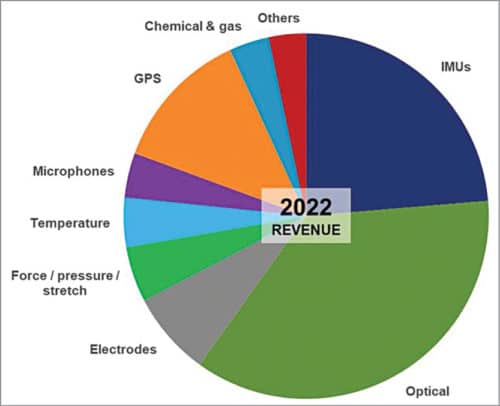

These latest sensors include medical sensors, GPS, inertial measurement unit (IMU) and optical sensors. With modern techniques and miniature circuits, wearable sensors can now be deployed in digital health monitoring systems. Sensors are also integrated into various accessories such as cloths, wrist bands, eyeglasses, headphones and smartphones. An IDTechEx report forecasts optical, IMU and GPS sensors to dominate the sensors market in terms of revenue by 2022 (Fig. 5).

Wearable applications and IoTs are expected to drive double-digit growth in the global market for sensors. Due to decrease in manufacturing costs and low power consumption of sensors, most traditional wired connections will be replaced with wireless sensors and integrated into wireless networks in the future.

Optical Image sensors

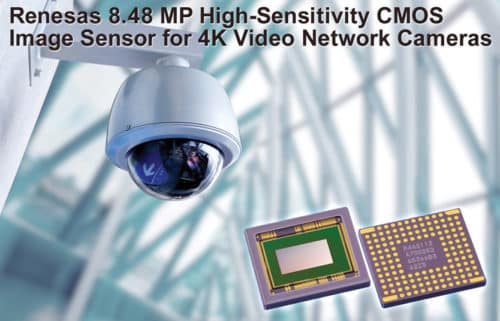

The best example of this sensor is found in your smartphone camera. An image sensor detects and conveys the information that constitutes an image. Digital imaging is fast replacing analogue imaging. Most digital cameras use CMOS sensors, which allow faster speed with lower power consumption.

These type of sensors are also used in automatic doors.

An image sensor from Renesas is shown in Fig. 6.

Biometric sensors

The most common biometric sensor is your fingerprint module. R30x fingerprint module is quite popular among hobbyists and experimenters. The latest generation of fingerprint sensors from Qualcomm consists of sensors for display, glass and metal, detection of directional gestures, and underwater fingerprint match and device wake-up.

These sensors are designed as both an integrated solution with Qualcomm Snapdragon mobile platforms, and as standalone sensors that can be used with other non-Snapdragon platforms. Qualcomm fingerprint sensors for glass and metal are likely to reach the market in the first half of 2018.

Printed sensors

Sensors printed on flexible substrates are becoming popular. The next generation of printed sensors will enable applications ranging from human-machine interfaces to environmental sensing. The IDTechEx report predicts the market for fully printed sensors to reach $7.6 billion by 2027.

Printed sensors may have a very simple structure with only a few electrodes, while others are much more complex requiring deposition of multiple layers. What they have in common is the capability to be manufactured on plastic substrates, which offer advantages in terms of mechanical flexibility, thinness and weight reduction.

Ultrasonic Sensors

These type of sensors measures the distance of a target object by emitting ultrasonic sound waves, and converts the reflected sound into an electrical signal. Ultrasonic waves travel faster than the speed of audible sound and produced the results.

Passive Infrared Sensor

The Passive sensors measures infrared (IR) light radiating from objects in its field of view.

Humidity Sensor

A humidity sensor (or hygrometer) senses, measures and reports both moisture and air temperature. The ratio of moisture in the air to the highest amount of moisture at a particular air temperature is called relative humidity. Relative humidity becomes an important factor when looking for comfort.

MEMS

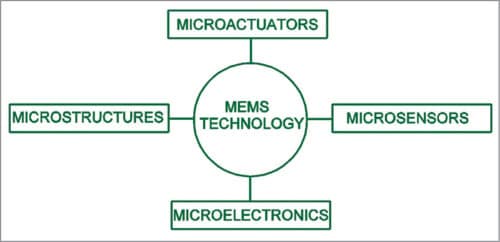

Microelectromechanical systems (MEMS) are devices characterised both by their small size and the manner in which these are made. These are made up of component sizes between 1 and 100 micrometres. The most notable elements are microsensors and microactuators.

MEMS devices can vary from simple structures to extremely complex electromechanical systems with multiple moving elements under the control of integrated microelectronics. In other words, MEMS sensor is a precision device in which mechanical part and micro sensors along with a signal-conditioning circuit are fabricated on a small piece of silicon chip.

Generally, MEMS consist of mechanical microstructures, microactuators, microsensors and microelectronics in one package. Fig. 7 shows the block diagram of a MEMS device.

Microsensors detect changes in a system’s environment by measuring thermal, chemical, electrical or mechanical information. These variables are processed by microelectronics and then microactuators act according to the changes in the environment.

Some common types of MEMS sensors available in the market are:

1. MEMS accelerometers. These are used to measure static or dynamic force of acceleration. The major categories are silicon capacitive, piezo-resistive and thermal accelerometers.

MEMS accelerometers are used in smartphones for various controls including switching between landscape and portrait modes, anti-blur capture and pocket-mode operation.

2. MEMS gyroscopes. These detect the angular rate of an object. MEMS gyros are used for vehicle stability control with a steering-wheel sensor and rollover detection.

3. MEMS pressure sensors. These sensors measure three types of pressures: gauge, absolute and differential pressure. The sensor is integrated with a diaphragm and a set of resistors on integrated chips so that pressure is detected as a change in resistance. These sensors are used in automotive, aerospace, medical, defence and industrial applications.

In automotive systems these are widely used in oil pressure sensor, crash detection, fuel-tank vapour pressure monitoring, exhaust gas recirculation, engine management system, etc.

4. MEMS magnetic field sensors. These sensors detect and measure magnetic fields, and find use in position sensing, current detection, speed detection, vehicle detection, space exploration, etc.

5. Fluxgate sensors. Fluxgate sensors are used to measure DC or low-frequency AC magnetic field. These find many applications like space research, geophysics, mineral prospecting, automation and industrial process control. MEMS-based fluxgate sensors score over other fluxgate sensors owing to their less power consumption, small size and better performance.

NEMS

Nanoelectromechanical systems (NEMS) are a class of devices like MEMS but on the nanoscale. These are the next miniaturisation step after MEMS devices. Nanoresonators and nanoaccelerometers are examples of NEMS.

Usually, NEMS rely on carbon-based materials, including diamond, carbon nanotubes and graphene. One of their most promising applications is the combination of biology and nanotechnology. Nanoresonators would find application in wireless communication technologies, while nanomotors might be used in nanofluidic pumps for biochips or sensors.

Sensor materials

The exact sensor materials depend on their type and application. For example, digital, analogue, proximity and image sensors have their own materials, structures, fabrication techniques and packaging.

Here we cover materials and fabrication techniques mainly for the latest sensors like MEMS commonly adopted by most manufacturers. Materials used in electronics can play an active or passive role. Some materials play both roles.

Passive materials

These are used to provide either mechanical structure or electrical connection. Some of these materials like silicon and gallium arsenide can also be used as active as well as passive materials.

Active materials

These materials are essential to the sensing process in microelectronics, photosensitive, piezoelectric, magnetoresistive and chemoresistive films. Microsensor materials in the form of thin or thick films play an active role in the sensing system. These devices are fabricated using chemical vapour deposition (CVD) or low-pressure chemical vapour deposition (LPCVD) and special techniques like electrochemical deposition.

Silicon

Elemental silicon is not found in nature, but occurs in compounds like oxides and silicates. Silicon is abundant, relatively inexpensive and exhibits a number of physical properties that are useful for sensor application. It is possible to deposit layers of materials with the desired properties on a silicon substrate. Single-crystalline silicon is the most widely used semiconducting material.

Polysilicon

Polycrystalline layers may be formed by vacuum deposition onto an oxidised silicon wafer with an oxide. Polysilicon structures may be doped with boron or other elements by ion implantation or other techniques to reach the required conductivity. The temperature coefficient of the resistance may be changed over a wide range, positive or negative—through selective doping. Polysilicon resistors have a long-term stability.

Other semiconductors

There is a wide range of compound semiconductors available to prepare heterostructures with unique properties. Gallium-arsenide (GaAs) and indium-antimonide (InSb) are widely used in electronic components.

GaAs. Gallium-arsenide is used in devices such as infrared light-emitting diodes, laser diodes, microwave monolithic integrated circuits (ICs) and solar cells. It is also used in optical fibre temperature sensors which measure temperature of the specified objects.

A study shows that some electronic properties of gallium-arsenide are superior to those of silicon. Gallium-arsenide transistors function at frequencies above 250GHz. Due to the superior properties of GaAs, these are widely used in mobile phones, satellite communications and radar systems. The highly sensitive GaAs piezoelectric sensors are also used for biological detection.

InSb. It is useful for magnetic sensing devices such as Hall Effect sensors and magnetic resistors. InSb magnetoresistors are used as position sensors in automotive applications. InSb materials are also used for infrared imaging.

Plastics

Plastics are widely used in electronic and electrical components and assemblies. Since plastics are insulators, these are used in a variety of applications where insulation properties are needed. Polymers are also used as radiation detectors and chemical sensors.

Metals. Physical properties and mechanical processing of metals are taken into account while designing sensors.

Copper has excellent thermal and electrical properties, but it is difficult to machine. Aluminium is used as an alternative in some cases. Metals are used in magnetic sensors. Precious metals like gold, silver, platinum, rhodium and palladium are widely used in sensor devices for automobiles, RFID tags, mobile phones and PCs.

Ceramics

Ceramics are widely used in sensor fabrication. These posses common properties including structural strength, light weight, thermal stability, electrical insulation and ability to bond with other materials. They do not react with oxygen and thus do not create oxides. Many manufacturers use ceramics as sensor substrates.

Sensor fabrication

Microsensor technology uses the basic fabrication steps followed in conventional silicon planar IC technique and some additional steps. At present, complementary metal-oxide semiconductor (CMOS) is the most common technology used in microsensors. Microsensors are designed and fabricated using commercial CMOS IC processes with subsequent bulk-micromachining technology. The exact steps are different from sensors to sensors.

Encapsulation

The chip must be protected from the atmosphere. Photoresist or silicon nitride materials are often used to cover the sensing area. LPCVD or CVD process is used to deposit silicon nitride layer, which acts as a barrier against water.

The next step is IC encapsulation. That includes sealing the IC in a plastic resin or metal case. This process protects the silicon device from the surrounding environment, and may not be always required in some MEMS devices where the atmosphere is used to transmit the measured quantity.

Deposition

Some sensors, especially MEMS devices, are required to deposit thin and thick film materials providing the sensing surface with the required properties. For example, sensitivity to thermal radiation is given by coating with nichrome. The film can be locally etched using lithography and wet chemical etching processes. Dry physical etching and laser processing can also be used.

The scope and future outlook

With micro and nano technologies, sensors can be made to fit almost anywhere in consumer devices that detect any motion or applications in robots, automobiles and even human bodies. Use of intelligent sensors is also increasing in counter-terrorism, cargo tracking, biometrics among other applications. Latest sensors are used in automobiles to prevent impending crash and determine the type of airbags to be fired, and force and speed of their deployment.

The use of MEMS in medical applications, including implantable devices and handheld devices for diagnostics and monitoring systems, is on the rise. Looking forward, with advancements in technology, the new wave of sensors including IoTs and wearables is going to revolutionise the electronics industry in years to come.