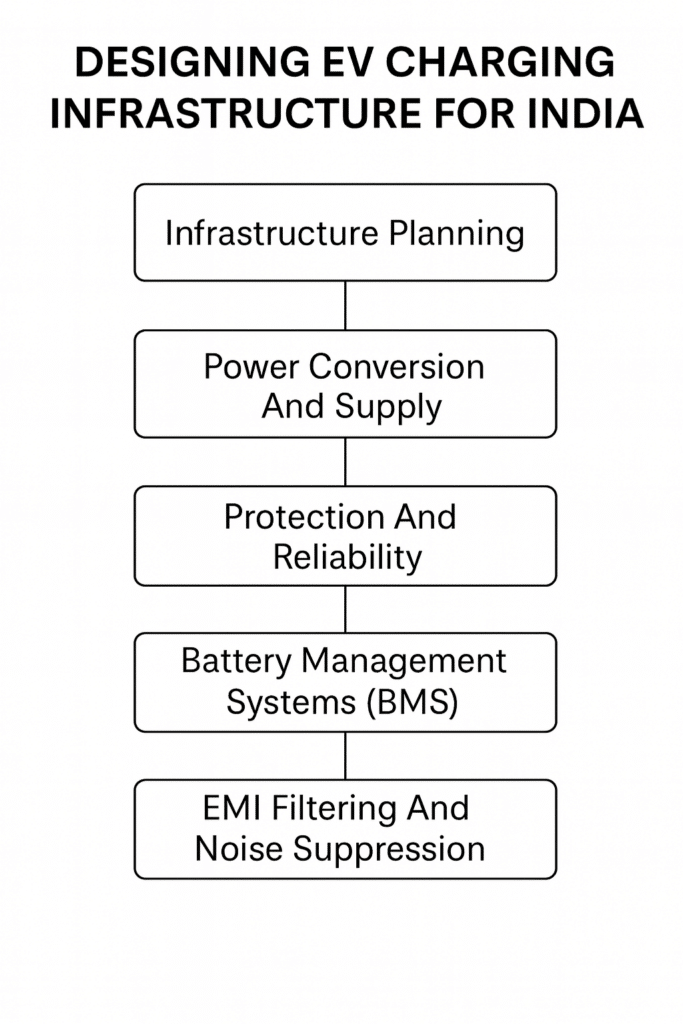

India’s EVs are on the upswing, but is the charging network ready? Read on to understand the technology and planning that could make or break the country’s e-mobility future.

The ecosystem of Electric Vehicles (EVs) is transforming quickly in India. This shift can work smoothly only if we build a strong and scalable charging network. Since India is a diverse country with different city layouts, terrains, and population patterns each region needs charging stations planned to fit its needs. Choosing the right charger types, connecting them to the grid, and placing stations across busy cities as well as far-off areas form the core of India’s e-mobility roadmap. Factors like grid load, limited land, high setup costs, uneven charger spread, and the push to link renewables make smart planning and efficient power use essential for a reliable, future-ready network.

The performance of India’s EV-charging network also depends heavily on the quality of the electronic components inside it. Consistent EV charging in India starts with the electronics inside the system. Power-conversion units keep the voltage firm, protection circuits secure against surges and faults, and battery-management electronics make sure charging stays safe and controlled. The unwanted signals can be suppressed using a few components. On the other hand,

the AC-to-DC and high-power DC-charging modules deliver fast, consistent energy. These parts together form the backbone of India’s EV-charging infrastructure.

Power Conversion and Supply

A safe EV charging system needs a power-conversion chain that can handle high voltages and deliver stable low-voltage rails. Apart from this it also maintains isolation under electrically harsh conditions. As India moves towards fast growth in both public and private charging infrastructure, the efficiency of these systems is greatly dependent on specialized converters and controllers that offer high efficiency, strong isolation, and compact designs. These components strengthen the auxiliary control domain and the high-power fast-charging stage.

In EV charging systems, different sections of the system have very different power requirements. Hence, the choice of isolated power devices depends on whether they serve control circuits or the main power stage. For instance, the Analog Devices Inc.(ADI) 505-ADUM6020-5BRIZ-ND can be applied to low-power isolated DC supplies for control and auxiliary circuits such as microcontrollers, sensors, communication modules, and small gate-drive circuits.However, it is not capable of taking care of the high-power AC-DC or DC-DC conversion in the main stages of charging, operating at kilowatt levels and requiring extensive isolation and thermal management. Thus, it fits the sections of auxiliary and control supplies of the EV charger, while the main power conversion requires dedicated high-power isolated converters.

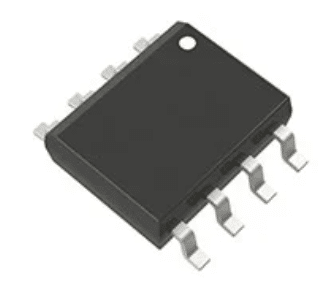

You might use a flyback converter to efficiently step down from high-voltage DC to low-voltage DC, with a lower component count and high performance. The Analog Devices Inc.(ADI) LT8302ES8E#TRPBFTR-ND is a small, low-power isolated flyback converter that senses the output directly from the primary side and requires no third winding or opto-isolator for voltage regulation. This simplifies the design and enhances the reliability of auxiliary power rails powered by low-voltage intermediate buses for applications such as EV chargers. Its typical efficiency under normal loads is around 80 to 85 per cent, depending on input voltage and output current.

In EV charging power stages, isolated supplies are needed for high-side and low-side gate drivers to safely control fast-switching SiC and MOSFET devices. The Murata 811-MGJ1D151802VMC-R7TR-ND DC-DC converter is designed for powering gate-driver circuits. One of its key features is very low isolation capacitance, which helps reduce common-mode noise transfer across the isolation barrier. The module includes reinforced galvanic isolation tested at approximately 5.2 kVDC and is designed for high working voltages.

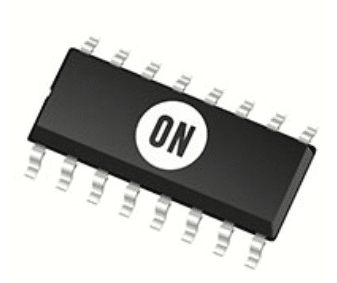

In the main power-conversion block, efficiency and power density become the priority. The onsemi NCP13992AADR2GOSTR-ND, a high-density current-mode LLC resonant controller, supports switching frequencies up to 750 kHz. Features like quiet skip mode improve light-load efficiency, which is important in EV chargers.

Protection and Reliability

Strong and resilient protection circuitry has become non-negotiable in India’s rapidly scaling EV-charging ecosystem. The power supply from the grid can be unstable, lightning can cause sudden spikes, and lots of devices in cities create extra electrical ‘noise.’ All this makes the electricity unpredictable. If the EV chargers don’t have strong protection, they can break early, become unsafe, or need costly repairs. “Beyond the standard electrical protections like surge, over-voltage, and short-circuit protection, physical security of the charger components is a major real-world concern in India,” added Sumit Chauhan from E-Fill Electric.

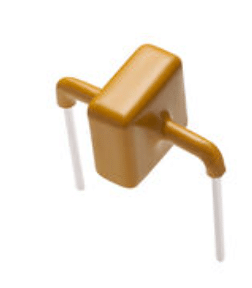

An example is the Littelfuse 18-AK6-058C-Y-ND TVS diode. These are discrete protection components designed to safeguard EV charging and power control circuits from voltage spikes and transients. With fast response, low clamping behavior, and robust surge-handling capability, they help protect sensitive power electronics and control systems from electrical stress on AC and DC lines. In EV charger designs, it is typically used as part of a multi-stage protection system to improve power reliability, enhance system uptime, and protect downstream electronics from grid disturbances.

High-speed communication inside charging stations also requires dedicated protection. The STMicroelectronics 497-18022-2-ND (HSP053-4M5) is a compact 4- unidirectional channel ESD protection array engineered for high-speed differential interfaces. In modern chargers, this device protects transceivers from ESD and noise. It can sit between the charger and controller or inside the EV for displays and touchscreens, keeping signals clean while providing strong IEC-rated protection.

Battery Management Systems (BMS)

BMS are the critical ‘brains’ behind any EV battery installation. As we know the main function of the BMS is to continuously monitor individual cell voltages, pack current, and temperature, while enforcing protective limits and ensuring consistent balancing across the battery stack. In India’s EV environment where the charger faces high heat, a robust BMS is a must to guarantee safety, longevity, and reliable performance over thousands of charge-discharge cycles.

One widely used solution is Texas Instruments (TI) 296-BQ7695202PFBRTR-ND. It is a highly integrated, high-accuracy battery monitor and protector designed for 3-series to 16-series Li-ion, Li-polymer, and LiFePO4 battery packs. It combines precise cell monitoring with a configurable protection subsystem and supports both autonomous and host-controlled cell balancing. The overvoltage and undervoltage detection, along with overcurrent, over-temperature, and short-circuit detection, make this a very suitable device for compact EV batteries. “Since the Indian electricity grid has its weak points, over- and under-voltage is common even in metro cities. So protection against over/under current over/under voltage is absolutely required,” added Arun Vijayan, Co-founder, Deepfleet.

For larger, high-voltage battery stacks such as those in cars, buses, or stationary storage, the Analog Devices 505-MAX17853ACB/V+-ND delivers a powerful solution. It can monitor 14 cells per IC, with differential cell-voltage measurement offering 1mV resolution and maintain accuracy across wide temperature ranges. Its built-in balancing switches support > 300mA balancing current, ideal for rapidly equalising high-capacity cells during charging. Thanks to redundant ADCs and comparator engines, the IC provides thorough diagnostics and safety alerts, while daisy-chaining up to 32 devices enables monitoring of hundreds of cells which is a necessity for high-voltage EV battery packs.

NXP 568-MC33771CTP1AE-ND is a high-accuracy battery cell monitoring IC widely used in EV battery management systems. It supports up to 14 Li-ion cells per module, including temperature sensor inputs, and robust fault detection for safer pack operation. With its iso-SPI daisy-chain communication, the device ensures reliable, low-latency data transfer across large battery stacks—critical for India’s fast-growing high-voltage EV charging and swapping infrastructure. It can be used for automotive EV BMS.

EMI Filtering and Noise Suppression

The power conversion electronics we discussed earlier can generate high-frequency noise in EV chargers. It can interfere with devices in their vicinity, and affect the performance of the overall system. In India we have seen, generally the chargers are installed closer to homes or offices, hence, the electromagnetic interference (EMI) control becomes crucial. Proper EMI filtering ensures reliable operation, protection of connected electronics, and safety and grid standard compliances for maintaining a stable and efficient charging experience.

The Murata Electronics 490-11818-2-ND (NFA21SL506X1A48L) is a small surface-mount LC EMI suppression filter designed for low-voltage, low-current signal or digital I/O lines. It is mainly used on signal or data lines to suppress noise, and can be applied in systems like EV control, monitoring, and communication lines, but not in high-power charging paths.

In EV charging infrastructure, controlling electromagnetic interference (EMI) is crucial for reliability and regulatory compliance. 490-GCM31A5C3A151FX01DTR-ND from Murata Electronics is a 150 pF, 1000 V C0G/NP0 multilayer ceramic capacitor with ±1 % tolerance, offering stable capacitance and minimal loss across temperatures. Its high-frequency noise suppression capabilities make it ideal for filtering DC bus lines and switching nodes in chargers, enhancing signal integrity and overall system performance.

AC and DC Charger Components

We have seen in our surroundings that there are 2 types of chargers, the AC and the DC chargers. AC chargers supply alternating current (AC) from the grid, which the vehicle’s onboard charger converts into direct current (DC) to charge the battery. In contrast, DC chargers convert AC to DC within the charging station, delivering DC power directly to the vehicle battery and bypassing the onboard converter. AC power, also commonly referred to as mains or utility power, is a constantly alternating type of current from power stations to homes and buildings. In contrast, DC power is a straight line type of current that can come from batteries, solar cells, fuel cells, generators, or be converted from AC using a rectifier.

The different components of AC EV chargers are designed to safely and effectively manage and regulate AC power. For instance, the Littelfuse S8016NRPTR-ND is typically used in auxiliary or AC line-control circuits, including phase control, input rectification, or switching low- to medium-power AC loads. It helps manage AC power within the charger. Still, it isn’t used as the main power-conversion device because it isn’t fully automotive-qualified for the high power and high reliability that EV chargers demand. Instead, it supports control and auxiliary functions in AC chargers rather than handling the core AC-to-DC battery charging. In India’s fast-growing EV-charging ecosystem, AC chargers rely on high-efficiency AC-to-DC conversion, where strong and reliable SiC switches keep the system stable, compact and efficient.

One more example can be, onsemi’s 5556-NVBG030N120M3STR-ND. It is a 1200V SiC MOSFET suitable for high-power AC chargers. It can handle up to 77A continuous current at 25 °C case temperature and dissipate 348W under ideal cooling. Its low on-resistance, modest gate charge, and low output capacitance help reduce conduction and switching losses. These features allow chargers to operate efficiently and reliably, but actual performance depends on proper gate drive and thermal management, especially in hot ambient conditions like those in India. “As the world is moving to SiC-based power devices, India needs to follow suit,” said Arun.

The DC fast chargers rely on high-voltage switching devices such as silicon-carbide (SiC) MOSFET modules. One example can be the onsemi’s 5556-NXH008T120M3F2PTHG-ND. These SiC MOSFETs waste lower energy, run cooler, and allow the charger to be more miniaturised and stable. They are especially suitable for chargers above about 15kW. Smaller parts inside the charger, like control, monitoring, and communication circuits, use separate low-power DC-DC converters for efficiency and safety. “The shift towards wide-bandgap semiconductors like SiC is a breakthrough in the EV charging landscape. These allow for more efficient, compact, and reliable power converters, which are crucial for high-power DC fast chargers,” added Sumit.

In a DC charger, small isolated DC-DC converters provide power to control, monitoring, sensor, and communication circuits. For example, the Murata 811-NXJ1S0505T6MC-R7TR-ND delivers 5V at up to 0.2A, making it suitable for low-power electronics in the charging system, while the main high-power conversion to the EV battery is handled separately.

Most modern high-power DC fast chargers use SiC MOSFET modules to achieve higher efficiency and compact design. Lower-power AC chargers and some older DC systems may still use silicon MOSFETs or IGBTs. Auxiliary DC-DC circuits typically rely on standard silicon devices.

India is speeding up large-scale electric mobility. The charging ecosystem can be improved by working on the new technologies and choosing the right components. Whether you are designing a power-conversion system or a BMS the technical backbone of modern charging stations lies in the components you use. Using the right components and following charging standards for India you can build scalable and a future-ready infrastructure.

| Key Technical Considerations |

• Future communication and grid: Vehicle-to-grid operation turns charging stations into grid-interactive devices, making real-time communication essential for control, safety, and coordination. • Flexible charging design: The right choice of connectivity depends on several factors, such as the use case and installation environment. While all commercial chargers require cloud connectivity for billing and vehicle data management, residential chargers require seamless integration with smart home networks. AC or DC charging options are supported by modular designs. • Safety and security: Secure software and processors are essential for monitoring charging levels, ensuring data quality, and providing a safe gateway for vehicle and payment information. |

| EV Charging Standards in India |

1. AC charging — Type 2 connector (Mennekes / IEC 62196 Type 2) • Used widely for AC (home and public) charging in India • Supports single‑phase or three‑phase AC, up to 32A and up to 22kW output 2. DC fast charging — CCS2 connector (Combined Charging System Type 2) • Standard for DC fast chargers for most 4‑wheel EVs in India • Supports high-voltage DC, up to ~1000V and ~500A (with liquid-cooled cables) • Typical public DC chargers deliver ~60–120kW; newer premium chargers going up to ~150–350kW. 3. Light electric vehicle charging standard (LECCS) connector (Type 7) / Type 6 connector (Dash‑6 / IEC 62196‑6) • LECCS (Type 7) is a combined AC/DC connector for scooters, e‑rickshaws, small EVs. Officially approved by BIS in late 2023 • LECCS supports up to ~7kW AC (240V, 32A) and ~10–12kW DC (120V, 100A) • Type 6 (IEC 62196‑6 / Dash‑6) is a DC-only standard used earlier for light EVs, delivering ~3–12kW DC 4. Bharat AC001 / DC001 • Bharat AC001: Low-power AC charging for 2‑/3‑wheelers and light EVs, 230V AC per socket, ~3.3kW per socket • Bharat DC001: Basic DC charging for small EVs, 48–72V DC, up to 15kW, faster than AC but lower than CCS |

| S.NO | Digikey Part Number | Specs | Brand | Image | Direct Links |

| 1 | 505-ADUM6020-5BRIZ-ND | 4.5–5.5 V input, 3.3 V or 5 V output, isolated | Analog Devices Inc. |  | click here |

| 2 | LT8302ES8E#TRPBFTR-ND | 1 output, 3.6 A, 8-pin SOIC with heat pad. | Analog Devices Inc. |  | click here |

| 3 | 811-MGJ1D151802VMC-R7TR-ND | 13.5–16.5 V input, +18 V/–2.5 V output | Murata Electronics |  | click here |

| 4 | NCP13992AADR2GOSTR-ND | Full protection, 20 kHz–750 kHz switching | onsemi |  | click here |

| 5 | 18-AK6-058C-Y-ND | 110V Clamp 6000A (6kA) (8/20µs) Ipp Tvs Diode Through Hole Axial | Littelfuse |  | click here |

| 6 | 497-18022-2-ND | 4‑line ESD protection, 5 V standoff and <1 nA leakage | STMicroelectronics |  | click here |

| 7 | 296-BQ7695202PFBRTR-ND | 48‑pin IC for 3–16 Li-ion/LiFePO₄ cells | Texas Instruments |  | click here |

| 8 | 505-MAX17853ACB/V+-ND | SPI/UART interface, ≥300 mA balancing | Analog Devices Inc. |  | click here |

| 9 | 568-MC33771CTP1AE-ND | 14Ch ASIL D Battery Cell Controller IC, TPL 2MHZ | NXP |  | click here |

| 10 | 490-11818-2-ND | 50 MHz cutoff, 20 mA/channel, –55 °C to 125 °C | Murata Electronics |  | click here |

| 11 | 490-GCM31A5C3A151FX01DTR-ND | 150 pF ±1% 1000V (1kV) Ceramic Capacitor C0G | Murata Electronics |  | click here |

| 12 | S8016NRPTR-ND | 800 V off‑state, 25 A RMS, 2400 A surge | Littelfuse |  | click here |

| 13 | 5556-NVBG030N120M3STR-ND | 1200 V SiC N‑MOSFET in D2PAK‑7 | onsemi |  | click here |

| 14 | 5556-NXH008T120M3F2PTHG-ND | Chassis-mount, 29-pin, size 56.7×42.5 mm | onsemi |  | click here |

| 15 | 811-NXJ1S0505T6MC-R7TR-ND | 1 Output 5V 200mA 4.5V – 5.5V Input | Murata |  | click here |