Precise humidity control is vital across various environments to preserve material quality and ensure optimal performance. In the textile industry, maintaining accurate humidity levels strengthens fabric, minimises static electricity, and prevents yarn breakage enhancing both product quality and machine efficiency. Consistent air moisture is equally critical in laboratories, greenhouses, hospitals, and other sensitive settings.

To achieve this, feedback-based humidity controllers are commonly used. The system described here automatically regulates humidity by continuously monitoring ambient levels and switching the humidifier on or off as needed. It operates using real-time data from a humidity sensor, with a feedback loop ensuring that conditions remain within the desired range at all times.

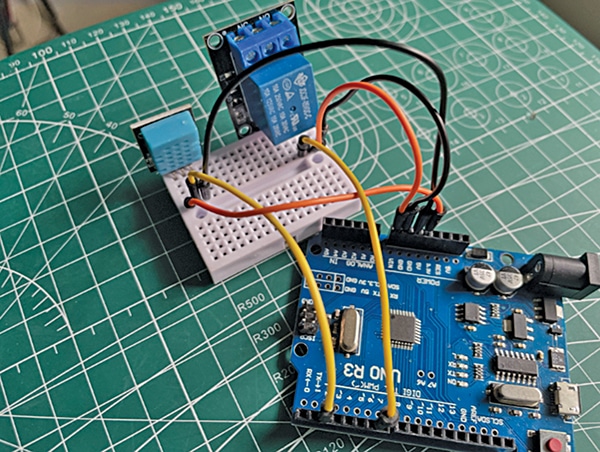

Fig. 1 shows a prototype built on a breadboard. The components required to build this system are listed in the Bill of Materials table.

| Bill of Materials | |

| Components | Quantity |

| Humidity and temperature sensor DHT22 (S1) | 1 |

| Arduino Uno R3 (MOD1) | 1 |

| Ultrasonic humiditifier | 1 |

| 5V SPDT relay module (RL1) | 1 |

| 5V adaptor or USB 5V power bank | 1 |

Circuit and Working

Fig. 2 shows the circuit diagram of the humidifier. The system is built around an Arduino Uno (MOD1), a 5V SPDT relay module, a humidity sensor (DHT22), an ultrasonic humidifier, and a few other components.