Overcurrent relays with inverse definite minimum time (IDMT) characteristics are widely used in power systems to protect electrical feeders and loads from overheating under abnormal operating conditions. In these relays, operating time decreases with increasing current magnitude, enabling a faster response to severe faults. The standard ANSI device number assigned to an inverse-time overcurrent relay is 51.

POC Video Tutorial

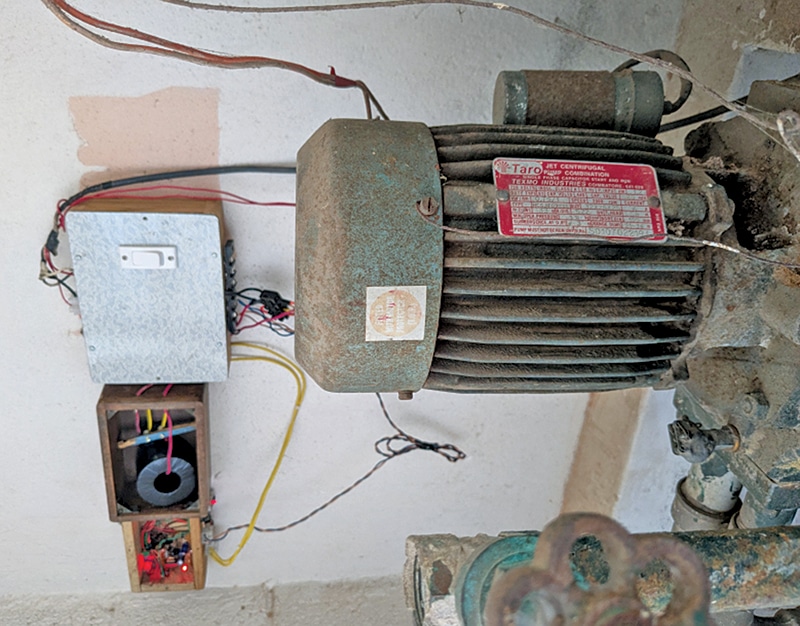

Although the proposed relay system is not thermal-based, it effectively emulates IDMT characteristics and is suitable for protecting induction motors, feeders, and other loads against prolonged overload conditions that could otherwise lead to winding failure or insulation damage. The implemented system, shown in Fig. 1, has been deployed on a domestic borewell motor to provide an alarm during overload conditions.

Circuit and working

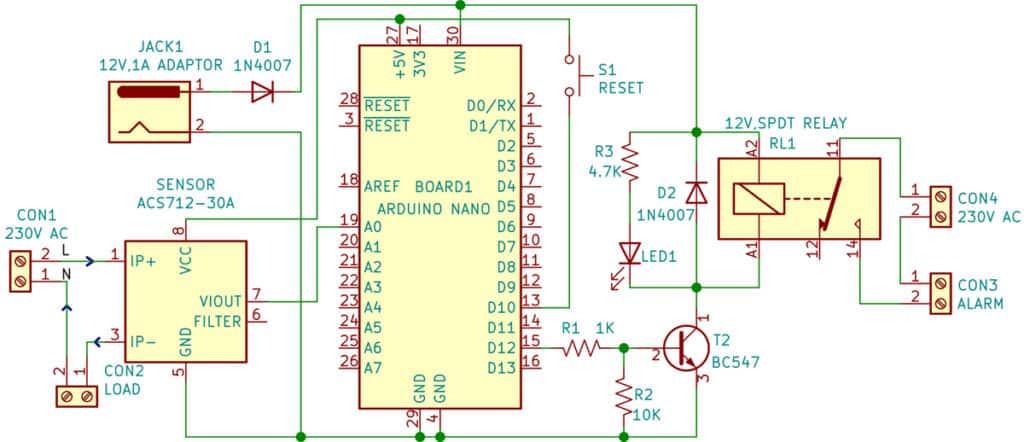

Fig. 2 shows the circuit diagram of the overcurrent/IDMT relay system. The system is built around an Arduino Nano, an ACS712 (30A) Hall-effect current sensor module, and a few supporting components. The load or feeder whose current is to be monitored is connected in series with the ACS712 sensor module.

The ACS712 operates on the Hall-effect principle and can measure both AC and DC currents. It can be connected directly in series with a 230V, 50Hz AC circuit, provided the current does not exceed the module’s rated limit.

In the implemented system, a relay is used to monitor an induction motor whose starting current exceeds the 30A rating of the sensor module. Therefore, a 30A/5A, 5VA current transformer (CT) is used to scale down the current under all operating conditions.

When a CT is used, the current transformer ratio (CTR=primary current/secondary current) must be specified correctly in the program. If the CT is not used, the software’s CTR value should be set to 1.0.

If a current transformer is used, the CT secondary must never be kept open-circuited while the primary is energised, as this may damage the CT, the circuit board, and pose a safety hazard.

The control circuit is powered by 5V DC from the Arduino Nano, supplied via a 12V, 1A adaptor. The output of the ACS712 sensor module is connected to the Arduino Nano’s A0 analogue input.

Working principle