The air conditioner outdoor unit design features MOSFET and power devices, vector control, and PFC technology for performance.

There has been a growing demand for low-power consumption in outdoor air conditioning units. Consequently, brushless motors powered by inverters with high-efficiency switching devices have become the norm for compressors and fans. Moreover, sensorless vector control is gaining popularity for motor control due to its ability to offer low cost, high efficiency, and reduced motor noise. Furthermore, there is an increasing need for smaller circuit boards in such equipment.

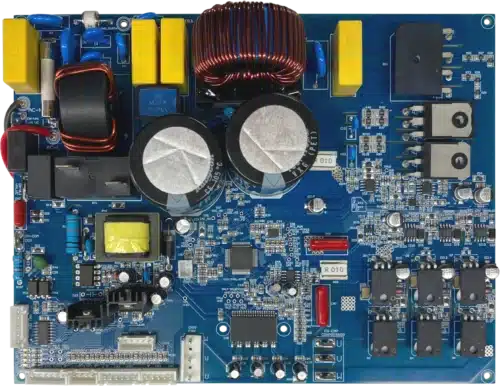

Toshiba’s air conditioner outdoor unit reference design utilizes a low on-resistance power MOSFET, TK20A60W5, for the compressor drive inverter to achieve a highly efficient compressor drive. An intelligent power device, TPD4204F, with an integrated gate driver and inverter circuit, is used for a compact and efficient fan motor drive. The PFC inductors are downsized by an IGBT device, GT30J65MRB, which has low switching losses and can operate at high switching frequencies in a switching PFC power supply circuit. Moreover, the use of the microcontroller TMPM4KLFYAUG, equipped with a vector engine, enables sensorless vector control of the fan motor and compressor, as well as PFC power supply control with a single microcontroller, simplifying and reducing the size of the outdoor unit circuit.

Furthermore, a transistor array, TBD62003AFG, is used as a valve control driver, a photocoupler, TLP785 serves as an insulating interface for communication between outdoor and indoor units, a SiC Schottky barrier diode, TRS24N65FB, is utilized as a PFC diode, a TC75W59FU is employed as an operational amplifier for signal amplification, and a TA75S393F is used as a comparator for detecting abnormalities.

The circuit is designed for an outdoor air-conditioner unit with an AC 200V input. It features a single microcontroller unit (MCU) that controls two motors and a power factor correction (PFC) circuit. The compact outline size of the circuit board is 160 mm x 220 mm. In addition to the MCU, the design includes optimal power devices such as IGBTs, power MOSFETs, intelligent power devices, and SiC Schottky barrier diodes to ensure efficient and effective performance.

In air conditioners, the compressor compresses refrigerant, which becomes high temperature and high pressure when compressed and low temperature and low pressure when expanded. This refrigerant is supplied to the outdoor unit for cooling and the indoor unit for heating. Fans help in efficiently exchanging heat. Motor drives operate compressors and fans, and using inverters has become familiar to increase energy efficiency. Power factor correction (PFC) circuits and inverters are crucial for reducing power consumption by efficiently converting and driving power.

Toshiba has tested this reference design. It comes with a bill of materials (BOM), schematics, a Gerber file, a printed circuit board (PCB) layout, and a schematic. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.