Inverters convert DC electricity from sources like solar panels, batteries and fuel cells into AC electricity. Their power-handling capacities like input voltage, output voltage and frequency depend on their design.

Inverters require a stable DC power source that can supply enough current for the required power demand. Apart from the design, the input voltage of an inverter depends on its intended application as follows:

1. 12V DC for smaller consumer and commercial inverters

2. 24V, 36V and 48V DC for home energy systems

3. 200-400V DC for photovoltaic solar panels

4. 300-450V DC for electric vehicle battery packs in vehicle-to-grid systems

5. Hundreds of thousands of volts for high power transmission systems

A wide range of applications including portable consumer devices, hybrid/electric vehicles, industrial control systems and solar power systems are driving the demand for inverters as these ensure a high-efficiency and high-reliability power source. Inverters help to save energy over conventional on/off control. Their faster switching enables more precise temperature control and reduced audible noise (in fan motors). Use of semiconductors in inverters helps to boost performance, minimise power losses and optimise thermal management.

Applications of inverters

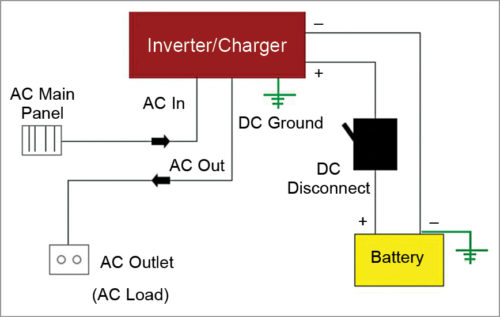

Inverters find diverse applications due to their DC-to-AC conversion function. Uninterrupted power supply (UPS) systems utilise inverters with a set of batteries to supply backup power when the mains power is not available. Inverter technology is advancing further, and many types of inverters are being manufactured and designed to serve different needs.

Other than for emergency backup power in homes, inverters are also used in some aircraft systems (to convert a portion of the aircraft DC power into AC), electric motor speed control, refrigeration compressors, power grid-tied solar power systems, induction heating, electric shock devices, etc.

Types of inverters

Different types of inverters are available for different applications: multilevel inverters, voltage source inverters, sinewave inverters, modified sinewave inverters and squarewave inverters. Voltage source inverters provide the required range of output voltage or current and frequencies. As these ranges are either positive or negative, voltage source inverters are known as two-level inverters. Multilevel inverters synthesise a near sinusoidal voltage from several levels of DC voltages. Minimum harmonic distortion is their main advantage.

Most of the pure sinewave inverters have good accuracy and very high load capacity, but these are complex in design and expensive. They power devices with less power loss and less heat generation. Sinewave inverters can be used for providing backup power to battery chargers, electric drills, electric tubelights, digital clock radios and other sensitive electronics.

The third and fifth harmonics in the output of a squarewave inverter may burn power and severely impact the efficiency of devices. These inverters are used in low-cost AC motor drives, induction heating units and electronic ballasts for fluorescent lamps.

Modified sinewave inverters can be used for most household electrical devices. However, these have a large amount of power efficiency loss due to significant harmonic frequencies. Also, as these inverters rely on the input power waveform for a clock timer, they will not work properly. Talking of advantages, modified sinewaves have very low harmonic distortion compared to the other waveforms. These inverters run inductive loads like microwave ovens and motors correctly; reduce audible and electrical noise in audio amplifiers, TVs, fans, fluorescent lights, fax machines and game consoles; and prevent crashes in computers, and glitches and noise in monitors.

Techniques to improve power conversion

Pulse-width modulation technique is used to power applications like electric tubelights, kitchen appliances, power tools, TV sets, radios, computers and many more electronics gadgets. This technique provides much cleaner AC power than modified sinewave and squarewave inverters. However, there are two major requirements: keeping inverter boxes watertight and using components that can withstand high temperatures. It is necessary to develop a system that can detect failure of any micro inverter and isolate it immediately.

Some of the techniques to improve power conversion efficiency of inverters are listed below:

1. To achieve zero-voltage switching, use an auxiliary inductor and two auxiliary switches in a single-phase inverter with neutral-point clamped topology and fixed-frequency PWM control. This can help to improve inverter efficiency.

2. To reduce total harmonic distortion as well as to control output voltage, use sinusoidal pulse-width modulation technique.

3. To improve the voltage, current or capacity level of power-conversion systems, connect multiple standardised modules in series or parallel at the input/output.

4. It is possible to protect inverters from inrush and over current automatically by adding clamp circuits to the resonant capacitance in parallel. High power-conversion efficiency can be achieved by regenerating the clamp current to the input voltage source.

5. To achieve near-zero common-mode voltage generation for a three-phase inverter, neutral-point diode-clamping is used. This solves desynchronisation issue of the balanced inverter.

6. A current-source-type four-switch inverter based on switch multiplexing technique can be used to reduce the input low-frequency current ripple as well as DC capacitor requirement. It is proved to be input-ripple-free and more efficient, and its size is much smaller because the DC capacitor size can be reduced significantly.

Way forward

We are moving towards solar power but it is still a developing technology with less than one per cent of consumers having access to it. So inverters are here to stay for at least next 50 years, strengthening the case for their improvement to make these more efficient.