Stand-alone ambient energy harvesting has become an important issue in the world of Internet of Things and medical implants, where batteries cannot be relied upon for long-time use. Here are some solutions that are emerging. But you need to select the right one for your application.

Advancement in low power electronics has paved the way to make a truly stand-alone ultra-low powered embedded product. This feat is made possible by ambient energy scavenging or, in other words, energy harvesting. Energy harvesting is a method of harnessing and converting the ambient energy into electrical energy for immediate use or to be stored for later usage. In short, energy harvesting makes it possible to realise the goal of a truly stand-alone system.

Selecting the right energy source is important for a design engineer as it dictates the run time, cost of operation, and even the size of the product. Battery needs to be replenished and any sort of non-renewable energy generation from any source like gas or solid fuel requires periodic refuelling, which is not possible for off-grid sensors and devices placed at remote locations. But the ambient environment contains energy which can be harnessed to run the low-power electronics for an extended period without any human intervention. Thus, the need for ambient energy scavenging arises.

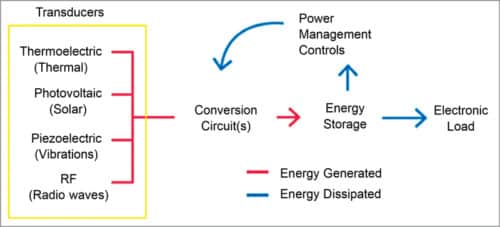

Energy harvesters are devices that can convert different forms of ambient energy into electrical energy, thus eliminating the requirement of a battery or extending the battery life of an ultra-low-powered system. It is a combination of transducers and power conditioning circuits. The energy can either be directly used to power a device, or the energy can be stored in a storage device for later use. The block diagram of an rnergy harvester is shown in Fig. 1.

The conversion circuit of an energy harvester usually incorporates a booster which increases the very low extractable voltage into higher voltage output capable of charging a cell or for directly powering a circuit. Some models also incorporate maximum power point tracking (MPPT) algorithms to maintain the optimum current to voltage ratio so that it can capture the maximum amount of energy.

The main task of an energy harvester is to harness the energy and the most important ability of an energy harvester is power conditioning. Power conditioning is essential because the output from a transducer has low voltage and current and might be at wrong frequency. Further, the intermittent output makes transducers unsafe for directly driving a device or charging a battery. The energy harvester IC conditions the input power from the transducer and makes it usable.

Energy can be harnessed from different types of energy sources available in the surrounding environment. And the choice of energy harvesting technology depends on factors such as cost, power consumption, and availability near the device. Solar- and motion-driven are the most common types of energy harvesters while some others use thermal and radio frequency energy harvesting (RFHE).

Table 1 compares the power density of different ambient energy sources.

| Table 1 | |

| Power Densities Of Ambient Energy Sources | |

| Energy source | Power density |

| Solar | 10µW – 25mW |

| Thermal | 20µW – 10mW |

| RF | 0.01µW – 0.1µW |

| Vibration | 4µW – 100µW |

The different kind of energy harnessing methods—such as solar, thermal, and radio frequency energy harvesting—are briefly described below.

Solar energy harvesting

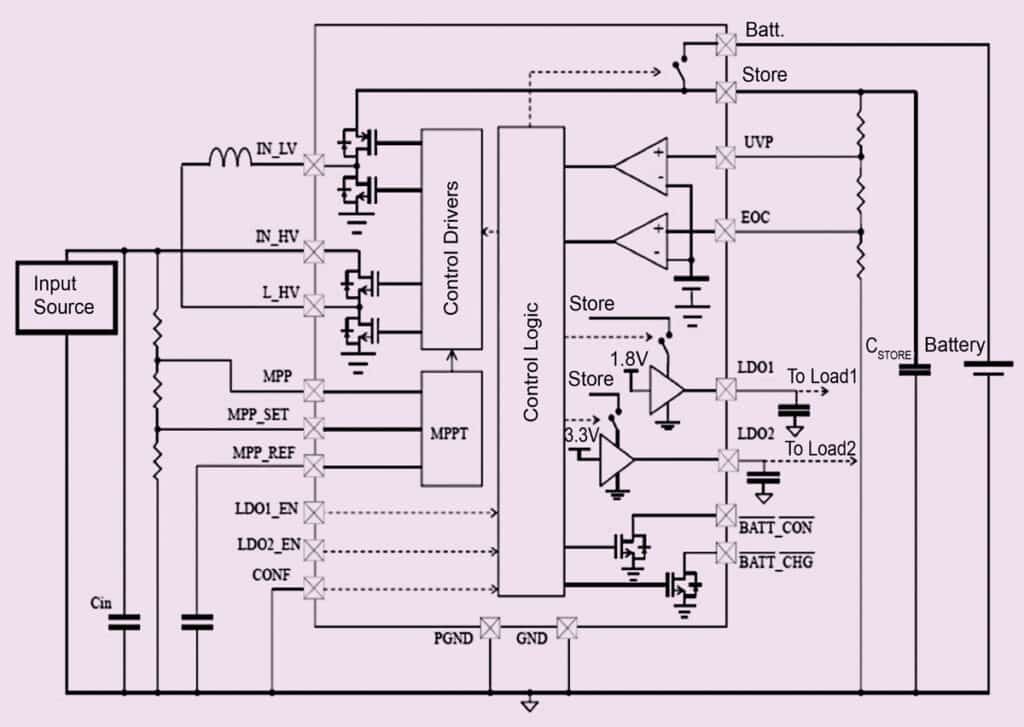

Solar energy harvesting is the most common type of ambient energy harvesting technique. The solar irradiance from the sun is readily available and the improvement of solar cells makes this a lucrative harvesting method in remote areas. ICs such as MAX20361 from Maxim Integrated and SPV1040 and SPV1050 from STMicroelectronics utilise an external solar panel to harness solar energy into an electrical voltage. These ICs utilise MPPT to harness the maximum amount of energy. They also have either a buck or a buck-boost converter to step-up or step-down the energy to be utilised for charging the battery. This harvesting method is a great choice in remote areas that have lots of sunlight. The application circuit of SPV1050 is shown in Fig. 2.

The main considerations while selecting a solar energy harvester are the type of storage devices it can charge, its input voltage, minimum cold start voltage, etc. Table 2 compares two solar energy harvesters.

| Table 2 | |||||||

| Comparison of Max20361 with SPV1050 | |||||||

| Model | Manufacturer | Storage type it can charge | Energy can harness | Input voltage (minimum) | Output current | MPPT | Cold start |

| MAX 20361 | Maxim Integrated | Rechargeable batteries, Capacitors | Solar | 225mV | 30mA | Yes | 225mV |

| SPV 1050 | ST Microelectronics | Rechargeable batteries, Capacitors | Thermal and solar | 150mV | 30-70mA | Yes | 500mV (Boost conversion) |

Thermal energy harvesting

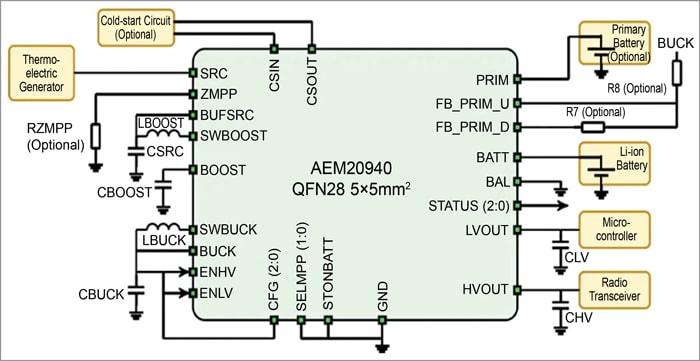

Thermal energy harvesting is the process of harnessing heat dissipated by machines or electronic components. Energy harvester ICs, such as e-Peas AEM20940 or STM SPV1050, are capable of thermal energy harvesting. These devices use thermos-electric generators (TEGs) as the transducers to convert ambient heat energy into electrical energy. Thermal energy harvesting finds usage in applications with a high heat loss, such as in power electronics circuits or electro-mechanical systems. A typical application circuit of e-Peas AEM20940 is shown in Fig. 3. Table 3 lists out the features of energy harvesters from STM and e-peas.

| Table 3 | |||||||

| Features of AEM20940 and SPV1050 | |||||||

| Model | Manufacturer | Storage types it can charge | Energy it can harness | Output voltage range | Output current | MPPT | Cold start |

| AEM20940 | e-peas semiconductor | Rechargeable batteries, Capacitors | Thermal energy | 2.2-4.5 | 80mA (max) | Yes | 380mV |

| SPV1050 | ST Microelectronics | Rechargeable batteries, Capacitors | Thermal and solar | 2.2-5.3V | 30-70mA | Yes | 0.5V (Boost conversion) |

Radio frequency energy harvesters

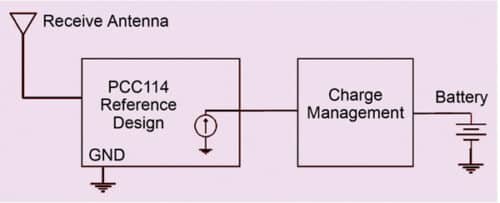

Radio frequency energy harvesting (RFEH) is a technique of harnessing energy from the electromagnetic (EM) waves produced by sources such as phone stations, TV and radio broadcasting stations, Wi-Fi routers, Bluetooth Low Energy (BLE), etc. As shown in Fig. 4, RF harvesting devices have antennas that receive the EM waves and convert them to DC energy, and charge management steps up the DC voltage to be used for power or charging a battery. Fig. 4 shows an RF energy harvester taken from the PCC114 datasheet.

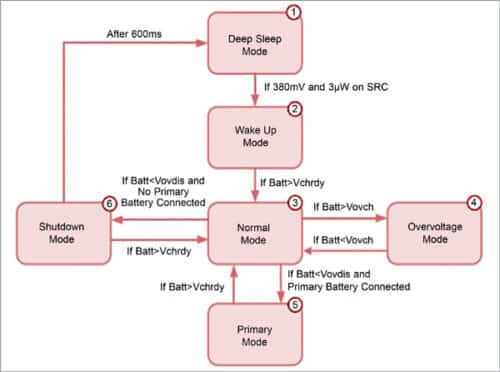

Radio frequency energy harvester (RFEH) devices like PCC114 from Powercast, AEM40940 from e-peas, and RFD102A from RF Diagnostics capture the electromagnetic vibrations of specific frequencies that are available around us to produce electrical energy. The flow diagram shown in Fig. 5 gives an overview of different modes of AEM40940.

RF power has lower energy density than most other sources, but this method is extremely useful for sensor nodes that are present in isolated areas with availability of no other ambient energies like solar, wind, or thermal. RFEH is commonly used for powering smart wearables, IoT devices, RFID tags, etc. Table 4 compares some common energy harvesting ICs from e-peas.

| Table 4 | ||||||

| Comparison of e-peas Energy Harvesting ICs | ||||||

| Model | Manufacturer | Storage types | Energy it can harness | Harvesting range | Output voltage range | MPPT |

| AEM40940 | e-peas semiconductor |

Li-ion, Capacitor | RF energy harvesting | 868-915MHz | 50mV-5V | Yes |

| PCC114 | Powercast | Li-ion, Capacitor | RF energy harvesting | 10MHz-6GHz | 4.3V | Yes |

| RFD102A | RF Diagnostics | Li-ion, Capacitor | RF energy harvesting | 60Hz to 6GHz | 4.2V | Yes |

Radio frequency identification (RFID)

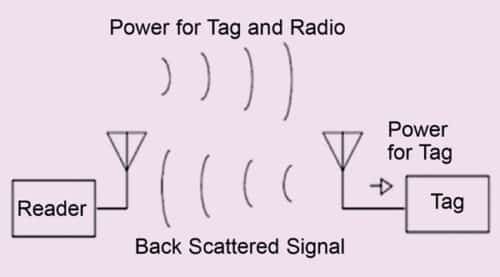

The passive RFID tags do not have any power source, they harness the energy from the radiated electromagnetic waves from the RFID readers. The coiled antenna within the tag forms a magnetic field and draws power to run the IC. The tag then sends the information over to the reader. The working of an RFID is shown in Fig. 6.

| Table 5 | |||||

| Comparison of Energy Harvesting Devices | |||||

| Model | Manufacturer | Energy storage type | Energy it can harness | Output voltage (max) | MPPT |

| AEM40940 | e-peas semiconductor | Rechargeable batteries, Capacitors | RF energy | 5V | Yes |

| AEM40940 | Powercast | Rechargeable batteries, Capacitors | RF energy | 4.3V | Yes |

| AEM40940 | RF Diagnostics | Rechargeable batteries, Capacitors | RF energy | 4.2V | Yes |

| AEM40940 | Maxim Integrated | Rechargeable batteries, Capacitors | Solar | 4.7V | Yes |

| AEM40940 | STM | Rechargeable batteries, Capacitors | Thermal and solar | 5.3V | Yes |

| AEM40940 | e-peas semiconductor | Rechargeable batteries, Capacitors | Thermal energy | 4.5V | Yes |

Near Field Communication (NFC)

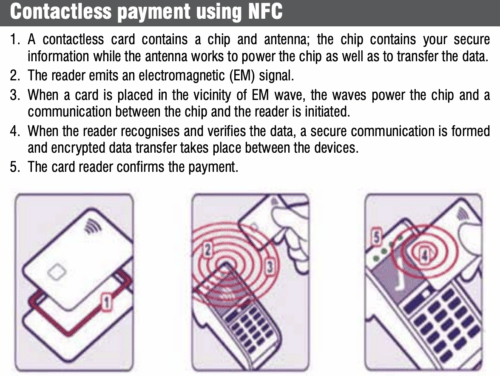

NFC is like RFID but works at a maximum distance of 10cm and on a frequency of 10.56MHz. It is a secure mode of data sharing and provides peer-to-peer sharing. NFC is used for various purposes, but one of the most common purposes these days is in contactless debit and credit cards for transactions. Its application is shown in the box below.

Where we can use an energy harvester

The IoT industry is growing at a compound annual global rate of 26.9% and the global IoT market size is expected to exceed US$870 billion by 2025. With the adoption of IoT and an increase in data sensing and collection, standalone systems make sense. Some of the applications of energy harvesting are:

- Wearable fitness

- Medical devices

- Industrial IoT sensors

- Asset tracking devices

- Wireless sensor networks

- Smart homes

- Smart agriculture

- Weather forecasting

- Smart cities

- Automobiles

The future of energy harvesting

The advancements in electronics industry pave the way for higher-efficiency components that will increase the adoption of energy harvesting techniques. Till recent years, most of the focus was on transducers which essentially made harnessing possible, but now companies such as Texas Instruments, e-peas, STM, etc are working on improving the energy harvester ICs. Some companies have started integrating ICs with on-chip energy harvesting solutions. Devices such as Atmosic ATM3 series Bluetooth SoC solutions have on-chip RF harvesting.

The growth in energy harvesting has accelerated with the start of Industry 4.0. The need for gathering data is growing at a rapid pace, which means more sensors are being installed even at the remotest of locations. Some application areas holding a great promise in the future are mentioned below.

Smart wearable technology. Wearable technology is capable of tracking and monitoring different parameters of our body. This technology is in high demand in wearable applications, such as smart fitness, smart healthcare, smart military, etc. The smart wearable industry is growing at an unprecedented rate and there is a huge demand in consumer-grade wearable devices, such as fitness tracking devices like Fitbit and infotainment devices like Apple watch. The smart wearable has a great scope of using piezo-electric transducers to generate energy and improve the battery life of the device. Mithras, a Switzerland based company, is developing TEGs compatible with wearable technology.

Self-powering medical implants. Bio-medical is another field where a lot of research is going on to harness the energy inside our bodies to extend the lifetime of implants that require electrical energy, such as sensors to monitor body’s parameters, pacemakers, and hearing aids, without changing the battery. Kinetic and heat energy can easily be harnessed. A joint mounted device based on generative braking can generate about 34W from the movement of knees and 20W from the ankles. Apart from thermal and kinetic energy harvesting, there are various other energy harvesting options where research is going on; one such method is blood sugar oxidation.

Vibration and kinetic energy harvesting. Any movement by anyone or anything results in vibrations that can be harnessed to generate energy. The movement causes vibrations or low frequencies in the range of 1Hz to 30Hz. Piezoelectric transducers can be installed in sidewalks, bridges, roads, and public areas, such as hospitals, stadiums, etc. Companies like London based Pavegen use electromagnetic induction to generate energy from people walking on the sidewalks.

The author, Sharad Bhowmick, works as a Technology Journalist at EFY. He is passionate about power electronics and energy storage technologies. He wants to help achieve the goal of a carbon neutral world.