In this article, our focus is related to air pressure while filling air in the tyre. This is important because the tyre may get burst and create many other problems due to excessive air pressure inside. So, we have proposed one method in which, one can detect the pressure of air in the tyre while filling air inside it. We have also compared our result with the desired one. So, by this method one can maintain the proper amount of pressure inside the tyre, also our method is cost effective.

In this article, our focus is related to air pressure while filling air in the tyre. This is important because the tyre may get burst and create many other problems due to excessive air pressure inside. So, we have proposed one method in which, one can detect the pressure of air in the tyre while filling air inside it. We have also compared our result with the desired one. So, by this method one can maintain the proper amount of pressure inside the tyre, also our method is cost effective.

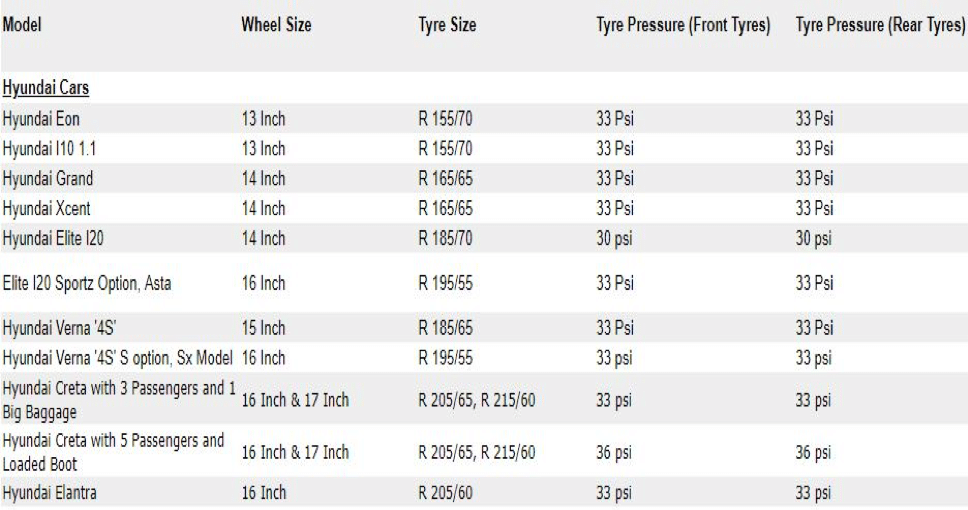

Common people always face problems of filling a proper amount of air inside the tube of a tyre. Many times they do not know the standard value of their tyre pressure & even if they know at the time of filling the air they are not sure about filling the proper amount of air. If proper amount of air is not filled as per the requirement then it may lead to many problems like reduced efficiency of vehicles, bursting of tyre, low life span of tyre, discomfort created while travelling on uneven roads, improper braking of vehicles, more wear & tear of tyre, overheating of tyre, increased chances of accidents, etc. So for avoiding this problem, we have developed a tyre pressure monitoring system which will measure the tyre pressure when the air is being filled inside the tyre & give an indication if more amount of air is filled in the tyre. There are already many tyre pressure monitoring system in existence but not all off them gives an indication that how much amount of air should be filled inside the tyre.

Comparison between different types of tyre pressure monitoring system on the basis of type of pressure transducer used & its measuring range [1]. Improving the privacy & security of tyre pressure monitoring system and other forthcoming in-car wireless sensor network [2]. Hybrid tyre pressure monitoring system which contains the advantages of both direct and indirect tyre pressure monitoring system [3]. A tyre pressure monitoring system which continuously measures the temperature and inflation of tyre, this system works on a wireless sensor network using ZigBee and CAN communication protocol [4]. A tyre pressure monitoring system which is more secure and their system uses infeneon SP37 sensors along with light weight cryptographic designs [5]. A single strained based system which gives reliable information about inflation, vehicle load and rolling speed of tyre, at a low cost [6]. An automatize tyre pressure monitoring system that helps in reducing the number of accidents [7]. A short time fourier transform (STFT) to detect the effect of tyre inflation on suspension system and shown that how inflation in tyre affects vibration of car body [8]. A theoretical analysis and linear behavior of direct type tyre pressure sensor while the vehicle is operating, it also describe easy integration, maintenance and replace ability of tyre pressure monitoring system [9].

Problem Description

![inflation in tyre [10]](https://www.electronicsforu.com/wp-contents/uploads/2019/03/tyre-inflation-500x172.png)

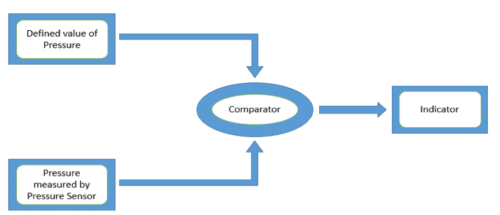

As shown in the figure 2, the comparator compares the pressure measured by the pressure sensor with the defined value of pressure and gives its output to indicator. If the pressure measured by pressure sensor exceeds the defined value of pressure then the comparator give positive signal to the indicator and the indicator shows its sign.

Material & Method

In our proposed method we have used MPX4250A which is an absolute pressure sensor. The table 1 shows the basic features of the sensor.

| Symbol | Characteristic | Min | Type | Max | Unit |

| POP | Pressure range | 20 | — | 250 | kPa |

| VCC | Supply voltage | 4.85 | 5.1 | 5.35 | Vdc |

| Io | Supply current | — | 7 | 10 | mAdc |

| Voff | Minimum pressure offset (0 °C to 85 °C) | 0.133 | 0.204 | 0.274 | Vdc |

| VFSO | Full scale output (0 °C to 85 °C) | 4.826 | 4.896 | 4.966 | Vdc |

| VFSS | Full scale span (0 °C to 85 °C) | — | 4.692 | — | Vdc |

| — | Accuracy (0 °C to 85 °C) | — | — | ±1.5 | %Vfss |

| ΔV/ΔP | Sensitivity | — | 20 | — | mV/kPa |

| tR | Response time | — | 1 | — | Ms |

| Io+ | Output source current at full scale output | — | 0.1 | — | mAdc |

| — | Warm-up time | — | 20 | — | Ms |

| — | Offset stability | — | ± 0.5 | — | %Vfss |

Table 1: operating characteristic of MPX4250A [11]

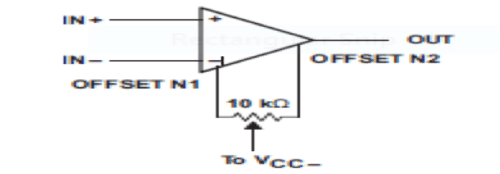

Also, we have used μA741IC as a comparator for comparing the output of pressure sensor with the given reference.

The μA741 device is a general-purpose operational amplifier featuring offset-voltage null capability. The high common-mode input voltage range and the absence of latch-up make the amplifier ideal for voltage follower applications. The device is short-circuit protected and the internal frequency compensation ensures stability without external components. A low-value potentiometer may be connected between the offset null inputs to null out the offset voltage as shown in Figure-3.

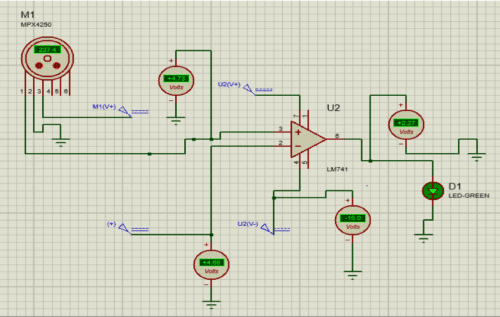

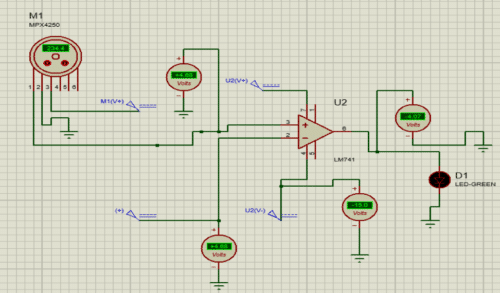

As we start filling the air inside the tyre, the pressure on the pressure sensor starts increasing, hence the output voltage of pressure sensor starts increasing. Here, the comparator continuously compares the output voltage of pressure sensor with the reference voltage. Once the pressure on the pressure sensor increases above the reference voltage then the LED starts to glow. As the LED glow, it will give an indication that you should stop filling the air.

As shown in figure-4, the pressure inside the tyre is less than “34psi” ( this is the standard pressure for particular types of tyre & it varies from tyre to tyre ) then the LED do not glow, which indicates that you can still fill the air inside the tyre to maintain standard pressure. Now as shown in figure-5, the pressure inside the tyre is increased more the “34psi” and so the LED starts glowing, which indicates that you should stop filling the air inside the tyre.

Different tyres have different standard pressure, hence the manufacturer should decide the reference voltage according to the type of tyre they are manufacturing.

Here, the output voltage of pressure sensor depends on the pressure, based on the following equation.

Vout = Vs ((P*0.009)-0.095) ± Error [11]

Where,

Vs: supply voltage

Vout: output voltage

P: pressure in “psi”

Result & Analysis

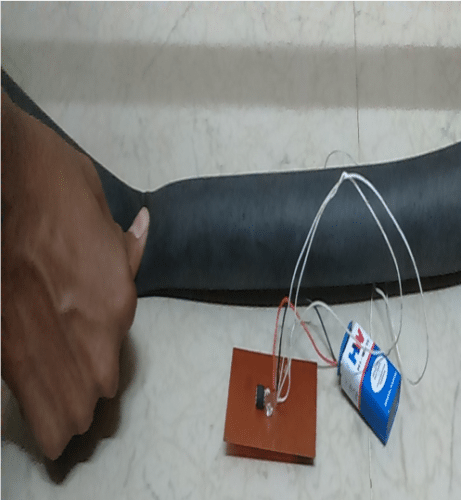

As shown in figure 6 & 7, we have made one circuit in which we have kept the pressure sensor inside the tube of the tyre. The pressure sensor is connected to the battery, LED & comparator which are placed outside the tube of the tyre. The figure 6 shows the condition when the pressure inside the tube is higher than the set value of pressure, hence the LED glows which indicates that we should stop filling the air inside the tyre. The figure 7 shows the condition when the pressure inside the tube is lower than the set value of pressure, hence the LED do not glows which indicates that we still have to pump the air inside the tyre.

| Pressure (psi) | Output voltage (volt) |

| 10 | 1.55 |

| 15 | 2.21 |

| 20 | 2.86 |

| 30 | 4.16 |

| 33 | 4.53 |

| 34 | 4.68 |

| 35 | 4.8 |

| 36 | 4.94 |

Table 3: Output voltage based on different values of pressure

Table 3 shows the values of output voltage given by the pressure sensor based on the pressure inside the tyre. We have considered a standard value of pressure to be 34psi.

Conclusion

The experimental results suggest that with the help of this method, we can fill proper amount of air inside the tyre as suggested by the manufacturer. Due to this, the pressure of the tyre is maintained equal to the standard pressure, which increases the overall efficiency of the vehicle and the user is made safe from bursting of the tyre by showing an indication of not filling more than required amount of air. This proper amount of air pressure inside the tyre provides more comfort to the user on uneven road. By use of this method the life span of the tyre would increase too.

References

- Kubba AE, Jiang K, “A comprehensive study on technologies of tyre monitoring systems and possible energy solutions”. Published 2014 Jun 11. DOI: 10.3390/s140610306.

- Ishtiaq Roufa, Rob Millerb et. all, “Security and Privacy Vulnerabilities of In-Car Wireless Networks: A Tyre Pressure Monitoring System Case Study”.

- Liqiang Wang, Bin Wang, et.all “Research of the Hybrid Tyre Pressure Monitoring System”. 2016 3rd International Conference on Mechanical, Industrial, and Manufacturing Engineering. DOI: 12783/dtetr/mime2016/10230.

- Asha Mathai, Dr.P.Vanaja Ranjan “A New Approach to Tyre Pressure Monitoring System”. International Journal of Advanced Research in Electrical, Electronics and Instrumentation Engineering. Vol. 4, Issue 2, February 2015. DOI: 10.15662/ijareeie.2015.0402067.

- Cristina Solomon, Bogdan Groza “LiMon – Lightweight Authentication for Tyre Pressure Monitoring Sensors”. CyberICS 2015, WOS-CPS 2015: Security of Industrial Control Systems and Cyber Physical Systems, vol: 9588, pp 95-111. DOI: https://doi.org/10.1007/978-3-319-40385-4_7

- Daniel Garcia-Pozuelo, Oluremi Olatunbosun, et.all “A Novel Strain-Based Method to Estimate Tyre Conditions Using Fuzzy Logic for Intelligent Tyres”. Sensors 2017, 17(2), 350; DOI: 10.3390/s17020350.

- Rajesh Kannan Megalingam, C Jayakrishnan, et.all “Automatic pressure maintenance system for tyres in automobiles to reduce accidents”. 2016 International Conference on VLSI Systems, Architectures, Technology and Applications (VLSI-SATA). DOI: 1109/VLSI-SATA.2016.7593028.

- Hamed, B. Tesfa, et.all “The influence of vehicle tyres pressure on suspension system response by applying the time frequency approach”. Centre for Efficiency and Performance Engineering, University of Huddersfield, Huddersfield, UK. 2013 19th International Conference on Automation and Computing.

- Taikyeong Jeong. “Roundy, S.Energy harvesting for tyre pressure monitoring systems” design considerations Technical Digest Power of MEMS2008.

- Ideal Tyre Pressure as Recommended: click here

- MPX4250A, MPXA4250A, 20 to 250 kPa, Manifold absolute pressure sensor, on-chip signal conditioned, temperature compensated and calibrated