As industries worldwide embrace the shift towards cleaner and more sustainable electric mobility, this design offers efficiency, precision, and adaptability to ensure reliable and eco-friendly battery charging.

Charging solutions for industrial Light Electric Vehicles (LEVs) are becoming increasingly vital in today’s rapidly evolving industrial landscape. As businesses and industries worldwide seek to reduce their carbon footprint and enhance operational efficiency, adopting LEVs has gained significant traction. These electric vehicles offer a cleaner, more sustainable alternative to traditional fossil-fueled counterparts, making them essential in pursuing environmental sustainability and cost-effective operations. Ensuring a steady power supply for these vehicles is crucial to maintaining productivity and realising the full potential of electric mobility in industrial applications. The importance of robust and tailored charging solutions cannot be overstated in this context.

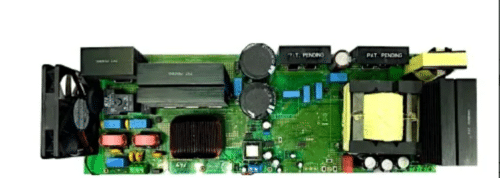

The ST Microelectronics reference design, STDES-2KW5CH48V, is tailored for charging industrial light electric vehicles (LEVs), including e-scooters, e-bikes, e-rickshaws, forklifts, micro e-cars, AGV robots, and power tools. Following the latest trends, it offers two charging profiles for Li-ion and lead-acid batteries. The charger features a boost power factor correction (PFC) circuit controlled by the L4984D for a high PF above 0.9 and a DC-DC circuit based on the L6599A-controlled full-bridge LLC resonant power converter with carefully chosen diodes. Ammicrocontroller manages power stages, battery profiles, protections, and the user interface, with MDmesh M5 power MOSFETs and SiC diodes in the PFC stage and MDmesh DM6 power MOSFETs in the LLC stage. The primary and secondary sections are powered by a VIPER16-based offline flyback circuit, ensuring stable voltages for critical components. Rigorous testing confirms outstanding performance, offering high efficiency, nearly unity power factor, and low THD under diverse input voltage and load conditions.

The multi-chemistry battery charger design incorporates a CCM PFC (Continuous Conduction Mode Power Factor Correction) and FB LLC (Full-Bridge LLC) converter to manage power efficiently. With a maximum output power of 2.5 kW, it can handle input voltages ranging from 85 to 265 VAC. The charger provides an output voltage of 40 to 60 V while ensuring that the maximum current does not exceed 42 A. Its control system utilises analog and digital elements, ensuring precision and adaptability. Achieving a peak efficiency of 93.75% from start to finish, it incorporates a soft start feature and a comprehensive safety mechanism to provide reliable and secure battery charging operations.

ST Microelectronics has thoroughly tested this reference design, which includes a Bill of Materials, Schematic Pack, CAD Design Files, Evaluation Board Terms of Use, Technical Notes and articles, Board Manufacturing Specifications and more. Please visit the company’s website for further information on this reference design. To explore this design in greater detail, click here.