We are building a simple touch-free automatic handwash dispensing machine.

Using discarded and waste household materials such as wooden drawers from broken tables, plastic bottles, PET jars, fruit juice packets, aquarium plastic pipes, and a few electronic components, this useful gadget has been developed as an effective tool to help prevent the spread of the coronavirus. It consists of a handwash liquid container, a submersible pump, a dispensing pipe, an infrared proximity sensor based pump control circuit, a power supply, and indicator LEDs.

When a hand is placed below the dispensing pipe, the proximity sensor activates the pump and automatically dispenses liquid soap or handwash without any physical contact. By eliminating the need to touch the machine, the risk of spreading infectious viruses is greatly reduced.

I have built several versions of this unit, a few of which are shown below, depending on the availability of materials. These touch free sanitizer and handwash dispensers have been donated to government hospitals and offices for use by visitors and frontline workers, including doctors, nurses, and healthcare staff.

Also, check the touchless water dispenser using Arduino.

Components Required

- IR Proximity Sensor module

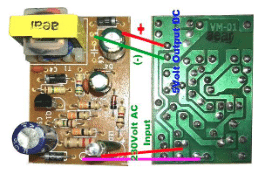

- 220 volt AC to 5 volt, 1A DC power supply module

- 6 volt DC mini submersible pump

- 10 mm dia plastic flexible pipe

- Plastic container for storing the liquid soap/ liquid sanitizer

- Outer Casing (wood/ card board)

- BC 547 / BC 549 (NPN/ PNP) Transistor

- 5 mm Green LED

- 100 Ohm Resistors

- 5v Relay

- 1N4007 Diode

- Wires

- Level showing LED / strip (optional)

- Piezo buzzer (optional)

Circuit and Working

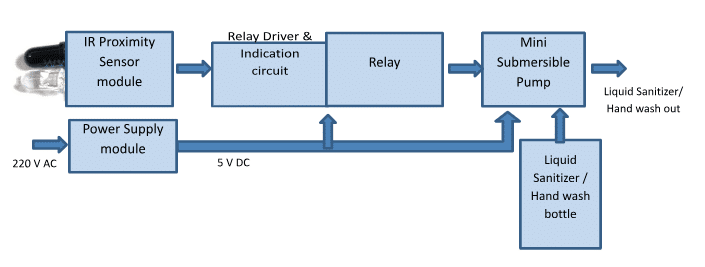

Block diagram of working principle of the Touch free automatic Sanitizer/ hand wash dispenser is shown in Fig.6:

Block Diagram

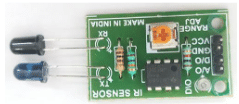

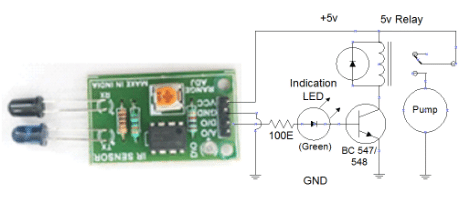

Whenever power is ON, the IR LED of IR Proximity Sensor continuously glows. In case of any obstruction to it like by placing hands in front of it, IR ray is reflected and falls on IR Diode. Falling of IR on IR diode causes changing of output status from either low to high or high to low depending on the type of IR Sensor. Author has used 2 types of sensors in different models. For type-1 sensor shown in Fig .2, LM358 based OPAMP comparator output changes from Low to High during any obstruction infront of IR LED & Photo Diode pair. This High signal is fed to the Base of NPN Transistor BC 547/548 via a 100 Ohm Resistor and a 5 mm Green LED. Thus the Transistor is switched On and 5v Relay is picked up whose coil is connected between +5v & Collector of Transistor. Emitter of the Transistor is kept grounded. When the Relay picks up, the Green LED glows and gives indication for operation of the relay and pump. Pump is connected to 5 volt DC supply via the NO contact of the Relay (Fig.7 Circuit Diagram). As soon as the Relay picks up, the mini submersible pump works and delivers liquid soap or sanitizer on hand through the plastic delivery pipe.

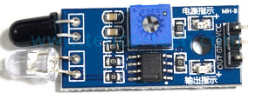

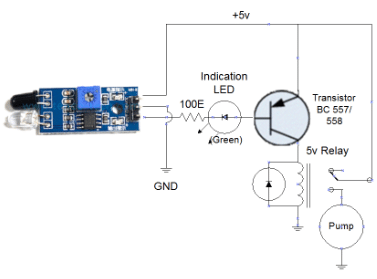

For type2 IR Proximity Sensor, shown in Fig.3, the output of the Comparator / Sensor remains On all the time. In case of obstruction i.e. placing of hand infront of it, the output changes from High to Low. This Low output signal is used to switch On the PNP Transistor BC 557/558 feeding to its base via 100 ohm Resistor and 5 mm Green LED. But here LED is connected in opposite direction. In this case, the relay coil is connected between Collector and ground and Emitter of Transistor is connected to +5v (Fig.8 Circuit Diagram).

In both the circuits, One LED and 9v small buzzer can be connected parallel to Pump for audio Visual Indication of operation of Pump. Moreover for visibility of liquid level in the liquid container, one White LED or a 4 V LED strip may be connected directly to 5 volt supply. But in case of LED strip, a separate power supply is to be used otherwise Pump will not run as the capacity of our power supply module (shown in Fig.4) used for the operation of the circuit is low (around 1A).

In both the cases a diode (1N4007 is to be used in reverse bias across the relay coil. It works as free wheel diode and bypasses the surge voltage during chopping of inductive load of relay coil and saves the transistor from damage.

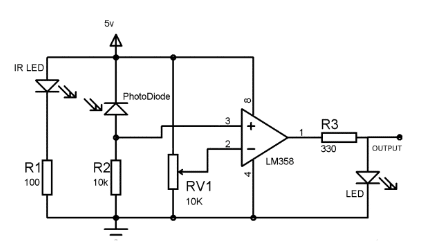

In case the readymade IR Proximity Sensor is not available, it can be made easily around Dual Comparator IR LM358. Circuit of IR Proximity Sensor has been shown in Fig.9. Here only one OPAMP of the IC LM358 has been used as comparator. IR LED glows continuously. In case of obstruction and thereby falling of reflected IR ray, causes flow of charges in photo diode, which in turn causes disturbance in balance between Inverting & Non Inverting Terminals and changes the Comparator output status from Low to High. That signal is used to switch the NPN transistor BC 547/548 and the Pump as described earlier.

Construction

In case the readymade IR Proximity sensor is not available, the circuit of the IR sensor can be built on zero PCB. For readymade sensor no PCB is required for connecting Power supply and Relays. All may be connected using wires and can be kept hidden inside the Outer shell of the dispenser.

Above mentioned Pump based circuits will work for liquid soap and liquid sanitizer only. This mini submersible Pump is not that much powerful to pump thick Jell type sanitizer or hand wash soap. For using thick jell of Sanitiser or Hand wash, another model of Touch free Automatic Sanitiser / hand wash dispenser may be made using same IR Proximity Sensor. In that case a gear motor and cam system is be used to press the hand pump of the sanitizer/ hand wash bottle instead of actuating the submersible pump. Author’s prototype has been shown in Fig.1.

Gautam Kumar Mandal is a Research Scholar, Seacom Skills University, West Bengal