Are hidden inefficiencies in your PCB production draining your budget unnecessarily? Maximise efficiency and cut costs with smart PCB Panelization.

Ordering a single piece of PCB from a manufacturer can be quite costly, especially when, for the same price, multiple PCBs could be manufactured and assembled. This is a common mistake made during initial product prototyping.

Focusing solely on circuit design and being unaware of PCB panelisation, this error often goes unnoticed until later. Even for those familiar with panelisation, it is possible to produce 3 to 4 more units at the same production cost by making slight adjustments to the panel design.

This article is intended for those new to the process, who may be overpaying for PCB manufacturing. Here are some key insights gained during the process of PCB and product design, highlighting ways to save costs in both prototyping and final product manufacturing.

Table of Contents

Also Check: High Speed PCB Design Guide

Prototyping Your PCB Design

In the prototyping phase, it is common to have two or more designs that require testing for reliability and functionality. Choosing the single PCB method for each design can be costly, especially as most manufacturers require a minimum order of 5-10 units.

Often, only one or two units are needed for testing during the prototyping phase, which can lead to unnecessary expenses during initial prototyping.

Panelised manufacturing can significantly reduce costs when prototyping multiple designs.

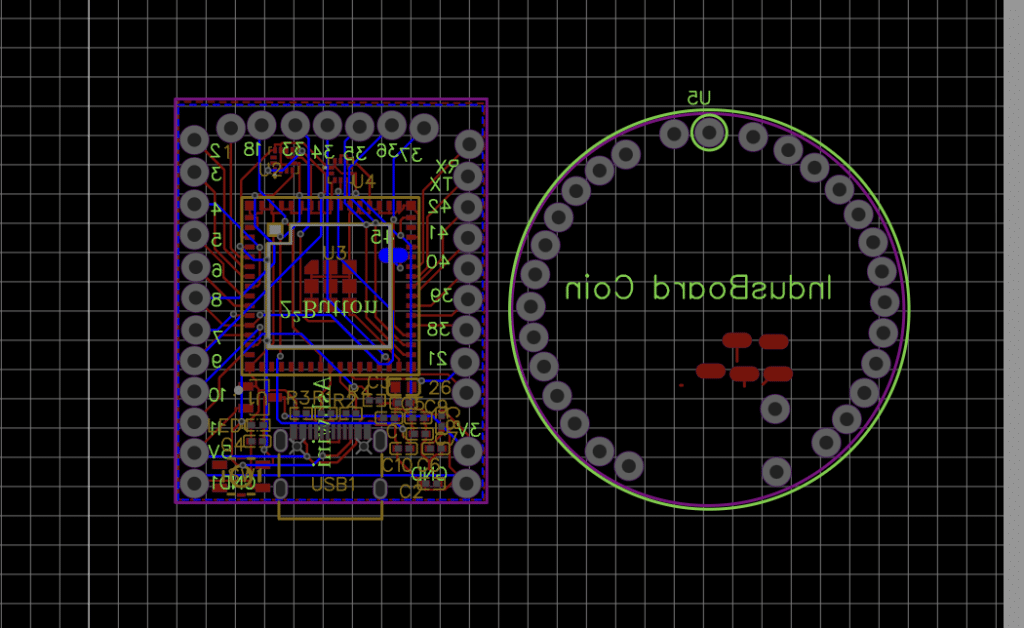

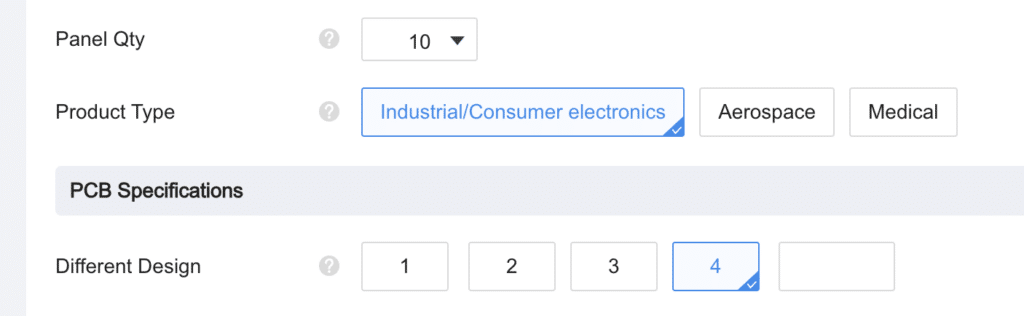

Panelising Different Designs

When testing multiple PCB designs during prototyping, paying for their separate manufacturing costs is unnecessary. By placing multiple designs (3-4) on a single panel, only one PCB cost is incurred, allowing the production of all designs for prototyping. This, however, depends on the PCB vendor. But most vendors allow this practice, charging for a single panel while accommodating multiple designs, thus reducing both PCB and SMT costs.

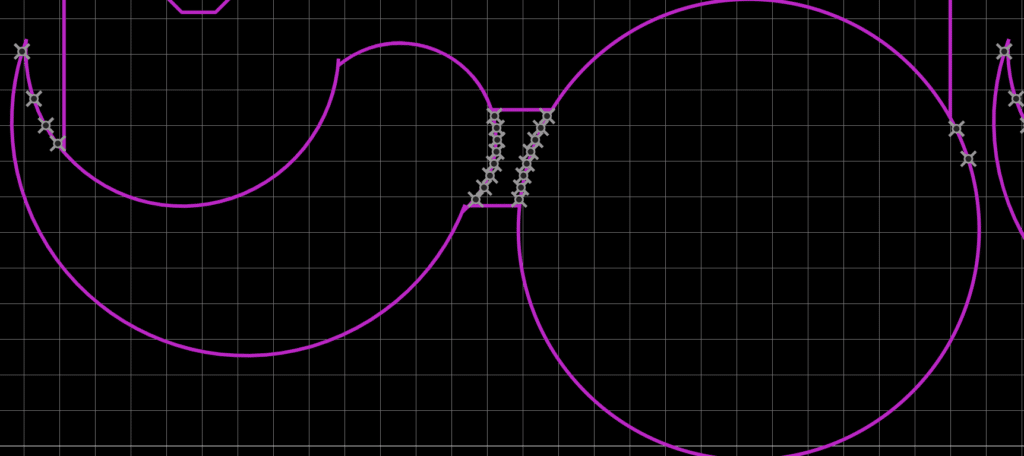

Panelising Different Shapes of PCBs