The new infrared sensing technology increases sensitivity for LiDAR and laser rangefinders, improving resolution and performance in various applications.

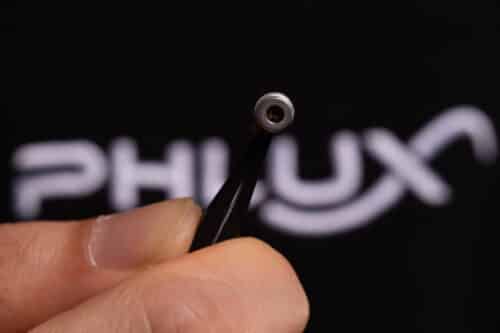

Phlux Technology, an avalanche photodiode (APD) infrared sensor manufacturer, announces its Aura family of 1550 nm devices using its Noiseless InGaAs APD technology. These sensors are more sensitive than traditional InGaAs APDs, allowing for an extended operating range of LiDAR, laser rangefinders, and optical fibre test equipment by up to 50%. Phlux sensors can replace existing surface mounts or TO-packaged components.

In new designs, Aura sensors increase LiDAR image resolution, reduce system size and weight, and lower system costs. This is achieved using lower-power lasers and smaller optical apertures without affecting system performance. Additionally, Aura APDs operate at higher temperatures of up to +85 °C without performance degradation, which is higher than traditional parts.

The company claims to have developed its Noiseless InGaAs APD technology by adding an antimony alloy to the compound semiconductor manufacturing process. The sensors from this process can operate with APD gains up to 120, amplifying small signals above the noise floor of a connected trans-impedance amplifier (TIA). Aura APDs also feature rapid overload recovery, allowing the detection of secondary pulses after a large pulse.

Both devices have a responsivity of 0.98 A/W at 1550 nm, a spectral range from 950 nm to 1700 nm, an excess noise factor of 1.86 at an avalanche gain of 40, and 1.08 at a gain of 10. Both devices operate at voltages between -55 and -65 V, have a breakdown voltage of -65 V, and an operating temperature range of -40 °C to +85 °C.

Phlux CEO Ben White said, “Our Noiseless APD technology is a step-function leap in performance and provides tangible benefits for any company involved with 1550 nm lasers. Automotive LiDAR is an exciting application where the move from 905 nm to 1550 nm lasers accelerates, not least because the latter is “eye-safe”. But there are also huge opportunities for our products in telecommunications, laser rangefinders, imaging, spectroscopy, gas sensing and optical fibre test equipment, particularly optical time domain reflectometers.”