Rice University engineers developed a scalable method to improve prelithiation, which involves coating silicon anodes with stabilized lithium metal particles to extend battery life.

The development of silicon anode batteries holds immense promise in revolutionizing energy storage capacities, a crucial element in achieving climate targets and realizing the full potential of electric vehicles. Nevertheless, the depletion of lithium ions in silicon anodes is an irreversible process that impedes the advancement of next-generation lithium-ion batteries.

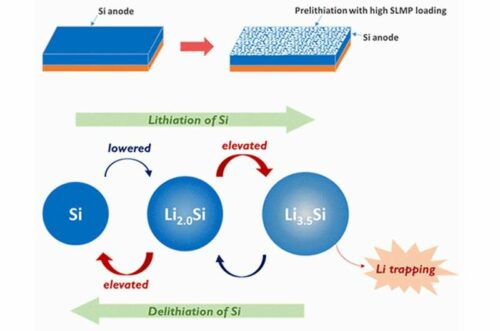

Scientists at Rice University’s George R. Brown School of Engineering have developed a method that can be easily scaled up to enhance prelithiation. This process involves coating silicon anodes with stabilized lithium metal particles (SLMPs) to reduce lithium loss and enhance battery life cycles. The team discovered spray-coating anodes with a particle-surfactant blend boosts battery life by 22-44%. Higher coating amount increased stability & cycle life but also caused more lithium trapping leading to quicker fading during subsequent cycles at full capacity.

Substituting silicon for graphite in lithium-ion batteries enhances energy density due to silicon’s ability to bond with up to four lithium ions, unlike graphite, which requires six carbon atoms for one lithium-ion. Electrolyte reaction with lithium ions creates a nanometer-scale layer of salts on the anode called solid-electrolyte interphase (SEI). The SEI insulates electrolytes from the anode and blocks the reaction. But the SEI can break during cycles, and its reformation further reduces the battery’s lithium reserve. Silicon anode’s changing volume during battery cycling can cause SEI instability, said Quan Nguyen, study’s lead author and chemical and biomolecular engineering doctoral alum. Stable SEI is desired throughout the battery’s charge and discharge cycles.

The researchers stated that prelithiation compensates for silicon’s usual lithium loss. It’s akin to priming a surface before painting so the paint adheres better. Prelithiation primes anodes, ensuring stable, long battery cycles. The researchers introduced a new element using a surfactant to disperse particles evenly, a previously unreported technique. This prevents clumping and ensures uniform distribution within the battery. Without surfactant, particle mixing with solvent does not give uniform coating. Spray-coating produces more uniform distribution than other methods, and it’s viable for large-scale production. If cycling capacity is not managed, more particles trigger the lithium-trapping mechanism. But cycling with uniform coating prevents lithium trapping.

The researchers believe that finding methods to prevent lithium trapping by optimizing cycling strategies and SLMP levels could enable better utilization of the higher energy density of silicon-based anodes.

Reference : Quan Anh Nguyen et al, Prelithiation Effects in Enhancing Silicon-Based Anodes for Full-Cell Lithium-Ion Batteries Using Stabilized Lithium Metal Particles, ACS Applied Energy Materials (2023). DOI: 10.1021/acsaem.3c00713