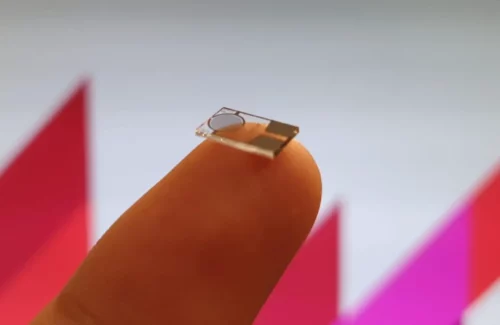

Engineers at Macquarie University have developed a new technique to create nanosensors, to reduce costs, carbon emissions, and manufacturing time.

Nanosensors comprise billions of nanoparticles deposited onto a small sensor surface known for their immense surface-to-volume ratio and consisting of layers of nanoparticles. They are susceptible to substances they are engineered to detect. Many materials can’t be used to make sensors because they can’t withstand heat, and the nanosensors containing tiny electrodes, like those in a nanoelectronic device, can melt. Traditionally, making these nanosensors requires energy-intensive processes and limited material options.

Engineers at Macquarie University have unveiled a method for producing nanosensors that reduces carbon intensity and costs while improving efficiency and versatility.

The researchers believe that the common occurrence where the initial fabrication of sensors tends to yield non-functional results, often necessitating further adjustments. Moreover, applying high temperatures in the furnace typically leads to the degradation or destruction of sensors based on polymer materials. The nanoparticles form a network through weak natural bonds, creating gaps between them that hinder the transmission of electrical signals, resulting in the non-functionality of the sensor.

The researchers have discovered that adding just one droplet of ethanol onto the sensing layer allows the atoms on the surface of the nanoparticles to move around without oven heating. The technique broadens the potential materials that can be used, expanding the applications and functionality of nanosensors. This simple addition activates the sensor in just a minute, enhancing its efficiency and responsiveness and outperforming the traditional 12-hour heating process results. The method’s effectiveness depended on careful experimentation to pinpoint the precise volume of ethanol required.

The technique eliminates the need for the traditionally heat-intensive procedure, thus opening up the possibility for the fabrication of nanosensors using an extensively diversified array of materials. This discovery has resulted in the complete transformation of a sluggish and energy-intensive process into an extraordinarily efficient one. The researchers behind this innovation have stated that the sample produced using this method has surpassed the performance of every single previous sample they have ever generated.