University of Houston researchers have created a revolutionary technique for 3D printing biosensors that one day may be inserted into human hosts.

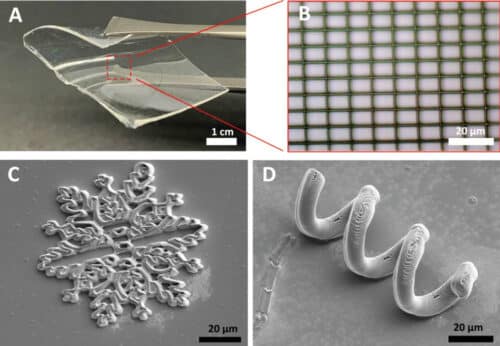

The team’s method comprises layer-by-layer polymerization of a resin filled with an organic semiconductor material using multiphoton lithography (MPL) to create tiny, biocompatible circuit boards. The technology developed by the researchers has so far been used to make extremely accurate glucose sensors, but with more R&D, they want to use it to develop a new line of bio-electronic gadgets.

“Here, a homogenous and transparent photosensitive resin doped with an organic semiconductor (OS) material is introduced to fabricate a variety of 3D OS composite microstructures (OSCM),” say the team in their paper. “[Our] results demonstrate the great potential of these devices for a wide range of applications from flexible bioelectronics, to nanoelectronics and organ-on-a-chip devices.”

The researchers claim that MPL is the “state-of-the-art” in Direct Laser Writing (DLW) 3D printing in their article because of the variety of materials it can work with and the high level of accuracy it can produce (down to a resolution of 15 nm). The Houston team believes that this makes the technology perfect for creating the kinds of nano-electronic devices that have been the focus of intense research in recent years.

The low conductivity of the materials used to make them, however, continues to restrict the practicality of 3D printing such bio-implants. The reason for this, claim the researchers, is that because carbon nanotubes or graphene are frequently used to make prototype bio-electronics, they have inorganic qualities that make them “difficult to disseminate homogeneously” in resins “without significant phase separation.”

For this reason, the Houston researchers have created their own MPL resin that can be precisely 3D printed into tiny bio-circuit boards with homogenous qualities. It is made of a PEGA polymer loaded with DMSO, a PEDOT:PSS organic semiconductor, laminin, and glucose oxidase.

The resin is loaded with proteins, then cultured inside mouse tissues for 48 hours. Compared to non-dosed samples, the lab’s cells showed evidence of “enhanced survival”. They used their resin to produce a novel bio-sensor capable of deploying electric currents to detect glucose levels. The team say their work could now help accelerate humanity’s progress towards cybernetic implants.

“We anticipate that the presented MPL-compatible OS composite resins will pave the path toward production of soft, bioactive, and conductive microstructures for various applications in the emerging fields of flexible bioelectronics/biosensors, nanoelectronics, organ-on-chips and immune cell therapies,” concluded the researchers in their paper.