Researchers have successfully developed an electrically driven biodegradable artificial muscle based on gelatin, oil and bioplastics.

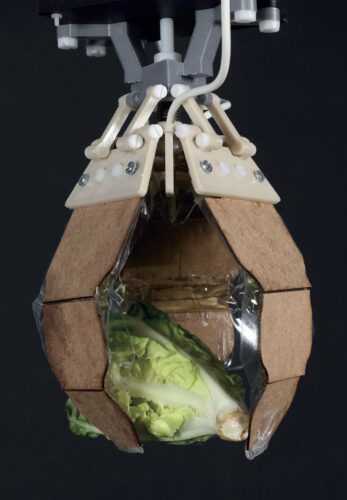

Artificial muscles are a progressing technology that could one day enable robots to function like living organisms. Such muscles open up new possibilities for how robots can shape the world around us; from assistive wearable devices that can redefine our physical abilities at old age, to rescue robots that can navigate rubble in search of the missing.

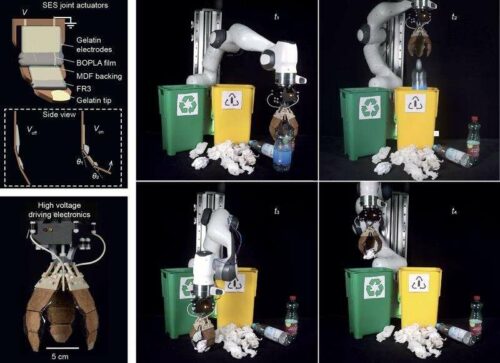

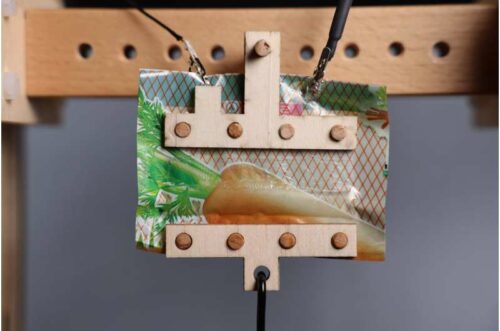

They built an electrically driven artificial muscle called HASEL. In essence, HASELs are oil-filled plastic pouches that are partially covered by a pair of electrical conductors called electrodes. Applying a high voltage across the electrode pair causes opposing charges to build on them, generating a force between them that pushes oil to an electrode-free region of the pouch. This oil migration causes the pouch to contract, much like a real muscle.

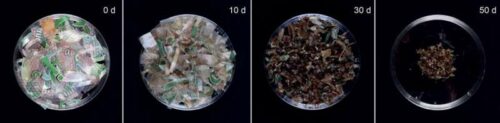

The key requirement for HASELs to deform is that the materials making up the plastic pouch and oil are electrical insulators, which can sustain the high electrical stresses generated by the charged electrodes. The next step was finding suitable biodegradable plastics. Engineers for this type of materials are mainly concerned with properties like degradation rate or mechanical strength, not with electrical insulation; a requirement for HASELs that operate at a few thousand Volts.

Some bioplastics showed good material compatibility with gelatin electrodes and sufficient electrical insulation. HASELs made from one specific material combination were even able to withstand 100,000 actuation cycles at several thousand Volts without signs of electrical failure or loss in performance. These biodegradable artificial muscles are electromechanically competitive with their non-biodegradable counterparts; an exciting result for promoting sustainability in artificial muscle technology.

Reference : Ellen Rumley et al, Biodegradable electrohydraulic actuators for sustainable soft robots, Science Advances (2023). DOI: 10.1126/sciadv.adf5551. www.science.org/doi/10.1126/sciadv.adf5551

great