This new research shows how 3D printers can learn from other 3D printers – A great example of “Group Intelligence”.

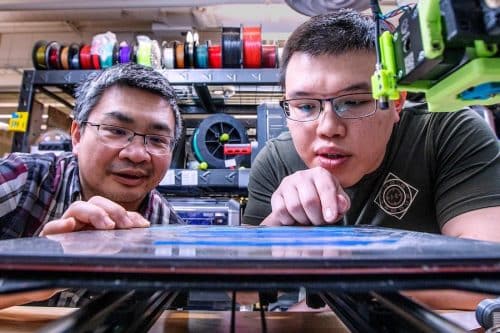

FAMU-FSU College of Engineering researchers are working to improve 3D printing technology by teaching machines to learn from one another. They demonstrated how data from one printer may be used to increase efficiency and quality in other printers.

“Cloud manufacturing, along with the Internet of Things (IoT), is a newly emerging technology,” said co-author Hui Wang, associate professor at the FAMU-FSU College of Engineering. “The technology demonstrates that data generated from multiple production machines can be shared with each in a timely manner, and manufacturing can be enclosed as an online service for meeting diverse market demands.”

The researchers are working on novel learning algorithms and printing process control methods. Variations in processing and faults in the finished structure can be caused by minute variances in the movement of a printer’s nozzle. Their method reduces printing flaws by sharing data among machines. This technique allows different printing processes to share their experiences, resulting in faster printing.

The researchers used a cloud platform to connect different printers, and then had the machines communicate data on accurate processing, reducing the time it took to prepare and calibrate them. According to An-Tsun Wei, a doctorate student in the college’s Department of Industrial and Mechanical Engineering and the study’s co-author, the researchers also constructed a mathematical model to better understand the printing process.

“We can estimate geometric print quality and the related defects that might occur with the model,” Wei said. “The information can be used to calculate adjustments needed in the input printing parameters to compensate for those errors.”

This transfer learning, according to Wang, is a method for achieving “group intelligence,” in which numerous learning agents (learners) collaborate to surpass a single learner. The method may be used on a wide range of devices made of various materials. The entire study has been published in IEEE Transactions on Automation Science and Engineering. You can find it here.