Researchers at the City University of Hong Kong and the National Renewable Energy Laboratory have developed a one-step coating method that simplifies Perovskite solar cell production.

Perovskite solar cells (PSCs) are a promising option for next-gen photovoltaics with high efficiency and low cost. The current layer-by-layer production approach has produced high-performance results. However, its issues, such as high fabrication costs, unevenness, and low reproducibility, may hinder commercialization.

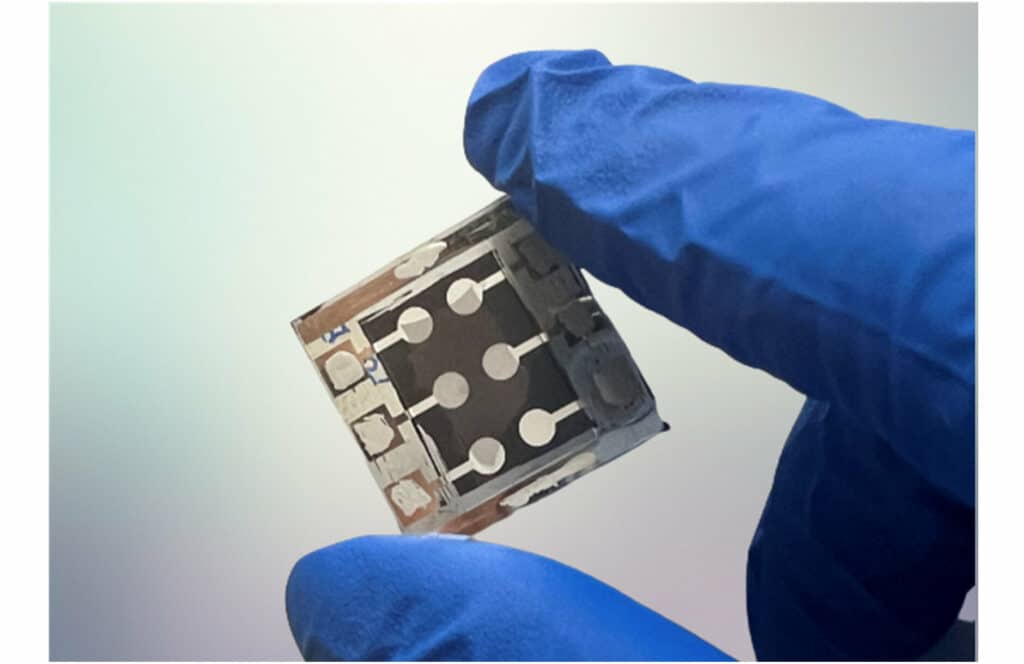

Researchers at the City University of Hong Kong (CityU) and the National Renewable Energy Laboratory (NREL) in the United States have jointly developed a groundbreaking one-step coating method, streamlining PSC production and reducing commercialization hurdles. Reducing processing steps, but maintaining device efficiency, can simplify manufacturing, lower costs, and improve PSCs’ manufacturability. The innovative co-processing technique combines the hole-selective contact and perovskite layer in one step, achieving 24.5% efficiency and remarkable stability in inverted perovskite solar cells. This advancement brings commercialization one step closer.

Researchers have created a new method for producing efficient inverted perovskite solar cells by allowing the hole-selective contact and perovskite absorber to form together in a single coating solution. Adding certain acids to perovskite precursor solutions enables self-assembly on the indium tin oxide substrate during perovskite film processing. The resulting monolayer is a strong, self-assembled hole-selective contact while the perovskite crystallizes. Unlike the traditional layer-by-layer process, this technique solves wettability issues and simplifies device fabrication by creating contact and absorber in one step.

The newly developed PSC device has a 24.5% power conversion efficiency and maintains over 90% of its initial efficiency after 1,200 hours of continuous illumination at maximum power. Its efficiency is comparable to similar market PSCs. The team demonstrated that the new approach works with various self-assembled monolayer molecular systems, perovskite compositions, solvents, and scalable processing methods, such as spin-coating and blade-coating techniques while achieving comparable PSC performance to other methods.

Introducing this innovative method hopes to simplify manufacturing high-performance perovskite solar cells and expedite bringing them to market. The team plans to study the connection between self-assembled monolayer molecule structures and perovskite precursors for optimum self-assembled monolayer molecules and PSC performance improvement.

Reference : Xiaopeng Zheng et al, Co-deposition of hole-selective contact and absorber for improving the processability of perovskite solar cells, Nature Energy (2023). DOI: 10.1038/s41560-023-01227-6