Researchers from Washington have demonstrated that 3D laser printing can be used to construct complex polymer optical devices directly on the end of an optical fiber

Traditional microscopic devices are expensive and bulky. To modify this, researchers invented a micro-optical device using 3D printing that consists of details smaller than the diameter of a human hair. This device would provide a very compact and inexpensive way to implement light beams for a variety of applications.

“Communication technologies, the internet, and many other applications are based on optical fibers,” said research team leader Shlomi Lightman from Soreq Nuclear Research Center in Israel. “When the light comes out of the fiber, large bulky optical elements are typically used to route it to the next location. Our approach minimizes both the size and cost for this process by integrating the routing process into the fiber itself.”

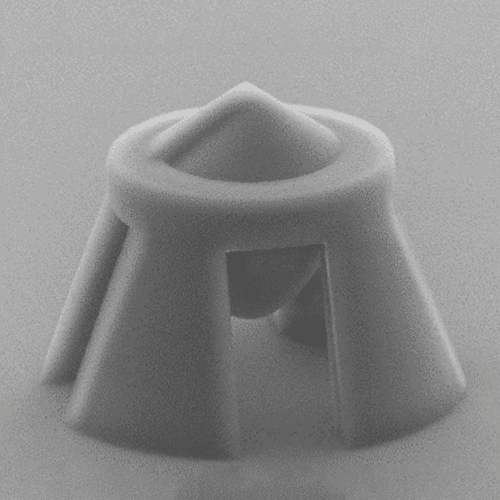

Researchers implemented 3D direct laser printing as a fabrication technique. The process uses a laser beam with femtosecond pulses to create two-photon absorption in photosensitive optical material. They utilized a commercial 3D direct laser writing system and a high optical quality photosensitive polymer to print a 110-micron-tall optical device 60 microns in diameter and 110 microns tall on the end of a single mode optical fiber only after careful analysis of results based on simulations. The device consists of a combination of both a parabolic lens for light collimation and a helical axicon lens that twists the light. This converts light exiting the fiber into a twisted Bessel beam.

“The ability to create a Bessel beam directly from an optical fiber could be used for particle manipulation or fiber-integrated stimulated emission depletion (STED) microscopy, a technique that produces super-resolution images,” said Lightman. “Our fabrication method could also be used to upgrade an inexpensive lens to a higher quality smart lens by printing a smart small structure on it.”

Researchers experimented with the optical device to examine its quality by building an optical measuring system to capture the shaped beam propagating from the modified fiber. They noted very low diffraction in the beam, which means that it could be useful for applications like STED microscopy and particle manipulation. They also noticed that the laser power could reach close to 10 MW/cm2 before damaging the fabricated micro-optical device. This showed that even if the device was made from polymer, which is more susceptible than glass to heat damage from high powers, it could produce relatively high laser power.

Even if this 3D direct laser printing is used previously, it’s difficult to correct the scale and alignment when fabricating such small optics on a fiber tip. “We were able to overcome this hurdle by performing highly accurate 2D and 3D simulations before we began the fabrication process,” said Lightman. “In addition, we had to carefully think about integrating the optical elements and then aligning that with the fiber core.”

Click here for the Published Research Paper