“The desire for more temperature-resistant power electronics was obvious, because the housings for power electronic components are traditionally installed as close as possible to the engine and should therefore have an equally high-temperature resistance”

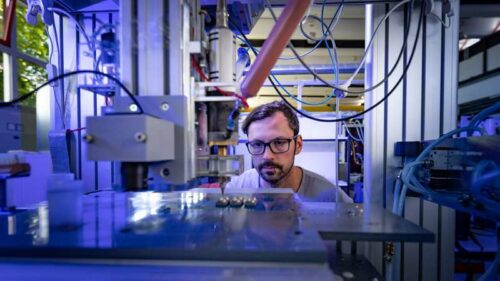

For the first time, researchers at Chemnitz University of Technology have successfully 3D-printed housings for power electronic components, which are used, for example, to control electrical machinery. Silicon carbide chips are placed at a predetermined location on the housing during printing.

The 3D printing of housings uses ceramic and metallic pastes, just like the printed motor made of iron, copper, and ceramics that the faculty first displayed at the Hannover Messe in 2018. “These are sintered after the printing process, together—and this is what makes them special—with the imprinted chip,” says Prof. Dr. Ralf Werner, head of the Professorship of Electrical Energy Conversion Systems and Drives.

The field-effect transistors’ gate, drain, and source regions are made contact with copper and are insulated with ceramic. “Contacting the gate area, which normally has an edge length of less than one millimeter, was particularly challenging,” adds Prof. Dr. Thomas Basler, head of the Professorship of Power Electronics, whose team supported the project with initial functional tests on prototypes.

The additively packaged silicon carbide-based power semiconductors have recently been the subject of multiple prototypes made by a research team under the direction of Johannes Rudolph, who contributed to the invention of 3D printing. “In addition to excellent temperature resistance, this technology offers other advantages,” Rudolph said.

The two-sided, flat, and solder-free contacting of the chips is anticipated to increase the chips’ use by improving cooling and extending their service life in terms of load cycles. “Due to the higher thermal conductivity of ceramics compared to plastics and the design freedom common to 3D printing, it is easy to realize specially adapted cooling geometries in the housing and on its surface,” assures Rudolph.