Think inductors are just coils of wire? Think again. These tiny components control power, boost efficiency, and make your devices run smoothly. Discover how they shape the tech around us.

When we hear the word inductor, most of us picture a coil of wire. That picture isn’t wrong. Coils are at the heart of what makes an inductor work. As current flows through a coil, it builds up a magnetic field, and when that field collapses, it pushes current back into the circuit. In simple terms, an inductor stores energy as magnetism and then releases it when needed. To learn the basics of inductors in an easy-to-understand format, check out this video.

Introducing the basics of inductors in an easy-to-understand video

What makes inductors really interesting is how they behave with different kinds of current. Direct current (DC) flows through them easily, but alternating current (AC) gets blocked more as the frequency goes higher. This means we can use inductors to pass DC while holding back AC, a feature that shows up in countless circuit designs.

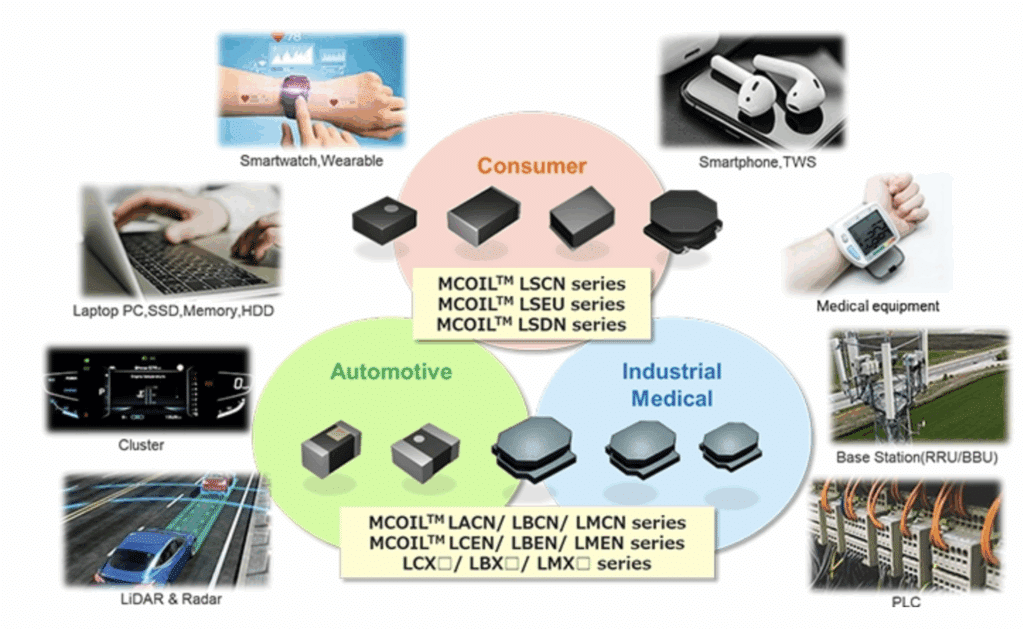

Not all inductors are the same. We can group them into high-frequency inductors, filter inductors, and power inductors. The ones we rely on most in power supply circuits are the power inductors. They’re everywhere—inside our smartphones and smartwatches, in the servers that power cloud computing, in communication stations, and even in cars. All of these systems need stable power, and that’s where AC-DC and DC-DC converters step in.

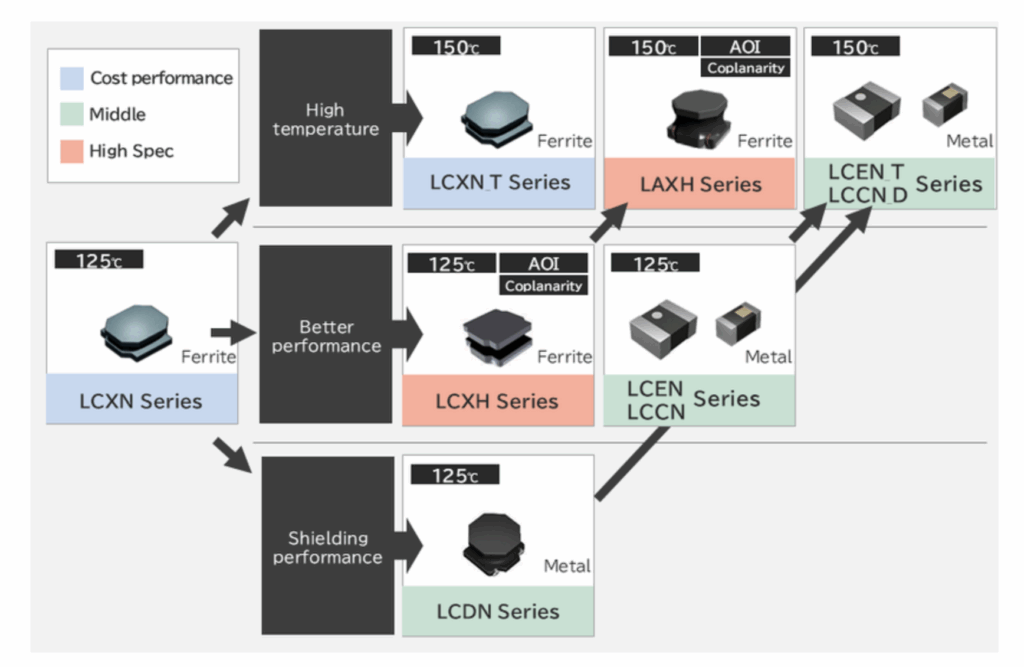

If we crack open a DC-DC converter, we’ll find a few key parts: a control IC, a switching element, a capacitor, and, of course, the power inductor. Here’s where things get fascinating. When the switch turns on, the inductor fills with magnetic energy. When it turns off, that energy flows out as current. The capacitor smooths everything out so the load receives a steady supply. Together, this process makes sure the voltage levels are just right for whatever the circuit needs.As design engineers, we often face the challenge of picking the right inductor. TAIYO YUDEN offers a comprehensive product lineup utilizing both ferrite and metal materials, as well as wound and multilayer structures, to meet a wide range of customer needs. For product selections tailored to specific markets and applications, please click here to access our product search system, “TY-COMPAS”.

Materials for Power Inductors

Traditionally, power inductors have utilized high-permeability ferrite materials, which allow for the realization of products with high inductance values—often exceeding 100 µH. These materials are particularly well-suited for applications that demand large inductance.

However, recent developments in power electronics have led to increasing demands for high current capabilities. As a result, metal materials with higher saturation magnetic flux density have gained significant attention.

One inherent drawback of metal materials is their relatively low magnetic permeability. To achieve high inductance, more winding turns are required, which in turn increases DC resistance (DCR). Fortunately, modern power supply designs typically operate at high switching frequencies (Fsw), significantly reducing the need for high inductance. In such scenarios—especially when the required inductance is below 1 µH—metal materials prove to be highly effective and broadly applicable.

For applications that require high inductance, we continue to recommend high-permeability ferrite materials. Conversely, for today’s increasingly common low-inductance, high-current applications, metal-based inductors are the optimal choice.

TAIYO YUDEN offers a comprehensive lineup of power inductors, including ferrite types that easily achieve high inductance values, and compact, high-current-capable metal types—such as our flagship MCOIL™ series.

Inductors Powering the Future

The global automotive-grade inductor market is expected to grow steadily, valued at USD 2.9 billion in 2025 and projected to reach USD 3.9 billion by 2035, with a CAGR of 2.9%. (Source: Automotive-Grade Inductor Market Forecast) This growth is closely tied to the increasing adoption of advanced electronic systems in vehicles, including infotainment, driver-assistance, and electric powertrains. The rise in electric and hybrid electric vehicles worldwide is a strong driver, as these technologies demand efficient power conversion and energy storage supported by high-performance inductors.

Technological progress is also shaping the industry. Wireless inductive charging components are emerging for applications such as electric vehicle and mobile device charging. High-frequency inductors, capable of operating in data transmission and signal processing, are gaining traction as well. The drive for miniaturization, energy efficiency, and integration with advanced circuits continues to fuel innovation.

Now, if we shift our attention to consumer devices, we’ll notice the MCOIL™ LSCN series of multilayer metal power inductors. Here’s the exciting part: these are about 40% lower in height than the earlier series. That means we can shrink devices like smartphones, AR/VR glasses, TWS earphones, and smartwatches even further. You can learn about the MCOIL™ line-up for the general market watch this video.

MCOIL™ line-up for general market

Another example is LSCND1006HK which is not just smaller but about 50% less in volume than its predecessor, making it ideal when we need to save space without losing performance.When we think about the automotive sector, we see how TAIYO YUDEN is helping us move forward. TAIYO YUDEN has also brought in four new multilayer metal power inductors, including the LACNF2012KK. What makes this one stand out is that it’s the world’s first multilayer metal power inductor to meet AEC-Q200 requirements and can handle up to 165°C. Thanks to their own metal materials and multilayer design techniques, we now have solutions that meet the rising demands of automotive systems. They’ve also brought out the LCQPB series of wire-wound ferrite power inductors, and these meet AEC-Q200 standards, so we know they’re ready for tough automotive use. We can use them as choke coils or noise filters in DC-DC converters inside body and information systems.

Beyond automotive, the market benefits from broader demand in renewable energy, consumer electronics, and connected devices. Industries are calling for inductors that not only manage energy effectively but also meet tight performance requirements. This creates opportunities in specialized designs, custom-switched inductors, and smart inductors, all of which support a range of applications from IoT to 5G networks.

Now we know that inductors are much more than just coils of wire. They’re the parts that keep our designs running smoothly. Whether we’re building smartphones, EVs, or next- generation communication systems, we rely on them to manage power and keep everything stable. As engineers, we have to think carefully about current, heat, and frequency when choosing the right part, and that’s where the latest innovations from companies like TAIYO YUDEN give us real options. Together, we’re designing for a future that demands smaller, smarter, and more reliable circuits, and inductors will continue to be at the heart of that journey.