In today’s world, robots are used to perform several types of tasks that were earlier performed by humans. Because batteries are the power source of robots, it is important not to take them for granted and regularly monitor and accurately test their health. Testing and measurement can provide information on whether batteries are fully charged, their current performance, safety maintenance, and much more.

In today’s world, robots are used to perform several types of tasks that were earlier performed by humans. From factories to offices, automation of these tasks, which were repetitive and consumed a lot of time, has resulted in improved productivity. According to various recent market reports, the robotics market size is going to grow even more in the future.

Because batteries are the power source of robots, it is important to regularly monitor and accurately test their health for the reliable working of these applications. Testing and measurement can provide information on whether batteries are fully charged, their current performance, the amount of charge left in the battery, safety maintenance, and much more.

What do battery ratings mean?

The chosen battery’s specifications should be able to meet the power consumption requirements of different components in a robot. Power limits vary depending on the country. In India, the power source is 230 volts, 50Hz alternating current. Energy density is the amount of energy stored in a given system or region per unit volume.

All batteries list a voltage and a capacity rating. Sometimes, a discharge current rating or burst current rating is also mentioned. Balaji Viswanathan, CEO, Invento Robotics, says, “Choice of the battery depends on energy density and safety. We are trying to run batteries for ten to twelve hours for our robots. We inform the users to charge when the charge reaches 25 per cent, and we are also working on an automated docking station to charge at that level.”

Voltage rating

The maximum terminal voltage that a battery can deliver to electronic components under ambient conditions is what the voltage rating mentioned on a battery means. Although 9V batteries are usually chosen for electronics, in a robot these cannot be used for the entire system. These can be used only for powering components like microcontrollers and sensors.

If a motor driver IC is being used, then also 9V supply for the logic side is sufficient. Motors draw much more power, so batteries rated AA, AAA, C, D, or battery packs suit the purpose. AAA, AA, C, and D batteries are each rated at 1.5V but vary in size, and the amount of current these can supply increases in ascending order.

Current or capacity rating

The amount of current per hour deliverable by a battery before getting fully discharged is known as its current or capacity rating. It is generally given in amp-hour or milli-Ah (mAh) based on the maximum output current. If a battery has a capacity of xy amp-hours at a current of y ampere, it simply means that y amperes can be provided to a load continuously for x hours.

Capacity helps in determining battery life. Motors need batteries with a high current output for proper functioning. The current rating needs to be more than the sum of the current requirements of individual motors.

C- and E-rates

C- and E-rates for describing batteries can be confusing for a beginner. The discharge current is mostly expressed as a C-rate to normalise against battery capacity. A C-rate measures the rate at which a battery gets discharged relative to its maximum capacity. A 1C rate would imply that the entire battery will take one hour to discharge.

Likewise, an E-rate is a measure of discharge power. A 1E rate is the discharge power needed to completely discharge a battery in one hour.

Battery selection for robots

The factors discussed in the previous section vary according to battery chemistry. There is always a trade-off between power and energy. Only one can be high, not both.

With so many types of robots in the market, selecting batteries can be confusing for a particular application. There needs to be a right balance between the weight of the robot, battery, and choice of motors. Listed next are some commonly used varieties.

Lead-acid batteries

Lead-acid or sealed lead-acid (SLA) batteries are useful for large projects where a large amount of current is needed for longer periods of time. These are cheap and do not require much maintenance. Their voltages are increments of 6V. However, these have low power density, lose capacity when idle, and cannot be used for lightweight mobile robots due to their heavy weight.

Nickel-metal hydride (NiMH)

These rechargeable batteries have been a popular choice on the economical side as these can fulfill capacitance and current output for many applications. The voltage rating of one cell is 1.2V, with a range from 600mAh to 3300mAh.

Also, these are safer than Ni-Cad batteries since these do not contain cadmium, which is a toxic element. However, these lose charge when idle and are getting replaced by lithium polymer batteries nowadays.

Lithium polymer (Li-Po)

These lightweight batteries are often found in electronic items these days. Along with high discharge rates, these are capable of delivering large amounts of power that are many times their capacitance. These batteries are available in a wide voltage range for various needs, in increments of 3.7V. S and P suffixes in ratings are used for series and parallel cells, respectively. However, these batteries need to be handled carefully and require a smart charger.

Lithium ion (Li-ion)

These rechargeable batteries (such as 18650 cells) are quite similar to Li-Po but differ in cell construction. These batteries are easily available, have stable voltage while draining and high capacity. These are also lightweight and safe when used with a battery management system. Unlike Li-Po batteries, these are preferred for low current requiring components like controllers and sensors.

Alkaline batteries

These non–rechargeable batteries usually come with 1.5V and 9V ratings. Duracell, Energizer, and Sanyo are some of the popular brands of alkaline batteries. These batteries are low-cost, have a high energy density, and are readily available. But these discharge quickly and have high internal resistance.

Testing and measurement

While designing batteries, quality assurance and safety testing are necessary for approval from government organisations and safety regulatory agencies. All the cell parameters a design engineer would need may not always be possible to quantify by direct measurement. Qualification testing, for example, checking for electromagnetic compatibility (EMC) compliance, is done before it is approved for use in a robot.

To determine whether a battery can fulfil the power demand when put to use in expected conditions, load testing is done. For knowing the ambient conditions for batteries, their behaviour under exposure to varied heat and temperature levels, altitudes, humidity, and fire is studied. Mechanical tests include options like vibration test, impact test, crush tests, shock test, nail penetration tests, drop test, among other similar ones.

Protection from or tolerance to issues such as overcharge (time/voltage), over-discharge, short circuit, misuse, or abuse is essential to ensure the safety of users. When it comes to measuring battery parameters for the robots, Viswanathan says, “We run batteries on a test bench with a constant load, and we also run road tests with more power drain.”

In a real environment, the parameters may be quite different from those calculated using assumptions. Testing is required to check the actual parameters during practical usage.

There are numerous devices available in the market for analysing, recording, and monitoring a battery’s parameters. Instruments and software systems that can measure and manage the life cycle of individual cells keep the user informed and ensure that the robot does not stop working all of a sudden.

For instance, SBS is a battery manufacturer that offers different battery testing, monitoring, and maintenance solutions that satisfy industry standards, besides safety programs. Calibration factors are built into any piece of test equipment due to differences in the aging profiles of the different battery chemistries.

Depending on the application, the device chosen for testing may just test the amount of charge present and/or its voltage output, or it may do a more comprehensive testing that keeps a tab on other parameters too. The most common way to measure a battery’s current state, often seen in schools and universities also, is using a multimeter.

While we may gain information on the state of charge, we still cannot determine whether the required amount of current will be delivered when demanded. Performance monitoring needs to be done on the user’s end to verify that a battery is performing as required when used in the application for which it was chosen.

The result

There are several terms whose values give an insight into a battery’s present condition once put to use. Whether or not to recharge or replace batteries depends on these values. Some of the parameters that different tools measure are explained next.

State of charge (SOC). It gives the present battery capacity as a percentage of maximum capacity. For many robotic applications, it is important to know the amount of energy left in a battery. It determines the change in battery capacity over time and is a crucial parameter in battery management systems.

State of health (SOH)

It is a measure of a battery’s ability to deliver the specified current when required. It is useful in understanding battery performance in real time during usage.

Depth of discharge (DOD). It is a measure of the battery capacity that has been discharged and is expressed as a percentage of maximum capacity. A discharge greater than or equal to eighty per cent is termed as a deep discharge.

Terminal voltage

It is the voltage between the battery terminals when the actual load is applied. It depends on SOC and discharge/charge current.

Open-circuit voltage (OCV)

It is the voltage between the battery terminals when no load is applied, that is, when the circuit is open. It determines the ability to deliver current but varies with SOC (directly proportional). After some time, as the battery begins to age, its ability to accept and to hold charge decreases. Hence, measuring internal resistance is necessary to get a complete picture of the situation.

Battery impedance (Z)

A combination of internal resistance and reactance is known as impedance. The resistance within the battery is known as the internal resistance. It depends on SOC and is usually different for charging and discharging. The current generated by the battery interferes with direct measurement, hence ohmmeter is not used.

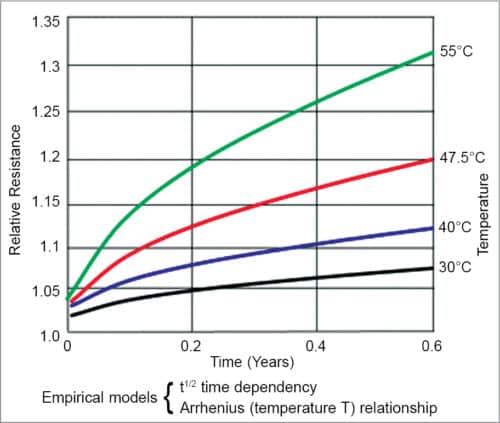

One method is to find the difference between terminal voltage and OCV, which gives IR voltage drop that corresponds to internal resistance. In another method, a small AC voltage of known frequency and amplitude is applied across the cells. Using Ohm’s law, the value of impedance is calculated. The higher the internal impedance, the lower is the efficiency and the thermal stability, since more of the charging energy is converted into heat (I2R). This indicates the SOH and measures deterioration in battery performance from the original.