To integrate systems and enable data sharing across them, well-defined standards and protocols are required. Global manufacturers must be aware of legal compliances in different countries where they operate while implementing changes.

Necessity is the mother of all invention. From the light bulb to the Internet, this holds true for every invention and discovery in the past centuries. But in today’s competitive market where there are so many options to choose from for each product, consumers are spoilt for choice. This decade has seen the fall of several businesses like Kodak that could not reinvent itself when people started growing exponentially on Instagram, Google’s Orkut when other social networks like Facebook gained more popularity due to an interactive and user-friendly interface, and so on. In simple terms, every business knows that consumers are the fulcrum for the success of any industry, but the ones who fail to meet growing customer expectations are the ones who lag behind.

Owing to quickly-changing consumer demands, innovative and fast-moving businesses are the need of the hour. Industries are undergoing a digital transformation that is capable of fundamentally altering the way factories and workplaces function. Technologies including Big Data analytics, artificial intelligence (AI), machine learning, cloud computing, the Industrial Internet of Things (IIoT) and industrial robots for smart manufacturing are a crucial part of Industry 4.0 and are responsible for the transformation. Industry 4.0 market is likely to reach US$ 156.6 billion from 2019 to 2024, expanding at a CAGR of 16.9 per cent, according to a report from Markets and Markets.

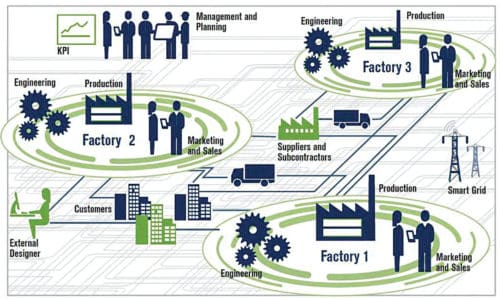

The impact is that data-optimised smart machines are connected to the entire supply chain so that manufacturing is in sync with the varying requirements and conditions in real time. Existing technologies like supervisory control and data acquisition (SCADA) systems and programmable logic controllers (PLCs) are also changing. Machines use sensors to collect comprehensive, real-time data that is crucial for decision-making using AI. Transparency and security are improved as data for tracking a product’s lifecycle gets stored in the blockchain. Increased use of 3D printing has resulted in faster time-to-market for many products. Even before the product reaches the market, technologies like augmented reality (AR) and virtual reality (VR) can be used for testing it. By deploying a 4G/5G network for wireless connectivity, processing of large volumes of data has become possible, and reconfiguration of the production line has become easier.

All these modifications eliminate inventory issues and significantly decrease production waste. In this article we discuss how customers are at the forefront of this revolution by being responsible for driving the creation of products of the future.

Innovative solutions for an enhanced experience

Manufacturers are increasingly integrating existing equipment with smart sensors to enable data collection in real time, which can be used for predictive maintenance and cloud-based AI. This saves consumers from inconvenience in the future. Germany-based ThyssenKrupp uses sensors to connect its elevators to the cloud. Data collected from the sensors is utilised for predicting when maintenance is required before the elevators break down.

Traditional mass manufacturing cannot fulfil the growing demand for customisation and personalisation for individual customers. This is further fuelling the growth of innovative solutions. For instance, US-based Local Motors realised that small factories can solve this issue. The company that earned limelight when in 2016 it unveiled AI-powered self-driving shuttle bus Olli focuses on low-volume manufacturing of open source motor vehicle designs and operates multiple micro-factories.

In 2018, Alibaba introduced G Plus, an unmanned logistics vehicle, which uses solid-state light-detection and ranging (lidar) technology to deliver goods purchased online to customers. It can carry several packages of different sizes and has a storage locker with facial recognition to keep food warm. This was done to decrease costs besides improving reliability and stability.

Connecting consumers to connected systems

Connected systems can detect flaws and communicate/automatically make amendments to prevent faults in the final product. By connecting consumers to the entire lifecycle of a product, companies can observe a significantly higher adoption rate. It is important to create transparency in the value-chain as consumers do not differentiate between manufacturers and resellers. Since the same high-tech product is available from several companies, consumers nowadays value their experience with the brand over product design.

One of the best examples is, probably, Tesla. According to a study conducted by Experian, Tesla owners showed a higher loyalty rate to the company than electric vehicles (EV) in general. Also, many people who had pre-ordered Tesla Model 3 in 2016 were later on informed that delivery would be delayed due to some manufacturing issues. But because of the company’s transparency regarding challenges, customers were willing to wait for years to get their vehicle.

Take Amazon’s example. Using machine learning, the company predicts its customers’ needs and views recommendations based on past viewing and order history. In addition, it caters to its key consumers through Prime Membership that offers greater benefits to members. By prioritising the satisfaction of its top clients, the business enables growth in its brand loyalty.

Many manufacturers are adopting Product as a Service (PaaS) business model to better support their customers’ needs. Most commonly, this is seen in the automotive sector where the present population is increasingly focused on usage over ownership. Consider Hyundai’s Shopper Assurance programme that is designed to make buying easier. This includes transparent pricing and flexible test drives to ease the purchase process. It also offers a three-day exchange in which if the customer is dissatisfied, the vehicle can be exchanged, or sometimes money is returned to the customer. Consumer preference for sharing economy has given rise to a number of startups in different fields, like Vacatia, LiquidSpace, Turo and Handy, among others.

Smart becoming smarter

Focusing on customer lifecycle is just as important as the entire product journey, if not more. Why connecting to the target audience is important? Because what worked in the past might be obsolete in the future. So, if your audience thinks your product is cool and serves the intended purpose(s), it is cool.

A proper customer relationship management system should be used by businesses to get an overall view of the end-user experience. An increasing number of companies are utilising AI-enhanced social media platforms, text messaging systems and chatbots for smooth communication with customers. Such startups as Avaamo, Kasisto, Cinnamon and Wysdom are developing AI-powered chatbots.

These technologies allow manufacturers to inform consumers about the benefits of their product(s) and get client feedback, which is necessary to make better products.

The concept of digital twins is also becoming quite popular in manufacturing due to its huge potential. Digital twins, a digital replica of a real-world entity, can be used for improving the process, predictive maintenance and gaining customer insight. Manufacturers can know which features are being liked by most users and where they are getting stuck. In a study of IoT implementation conducted by Gartner, thirteen per cent of organisations implementing IoT projects already used digital twins as of 2018, while 62 per cent were either in the process of establishing digital twins use or planned to do so.

User reviews also help other potential buyers make a decision about whether or not to buy a product. Unifying all these platforms enables quick identification of issues and streamlining of responses. This is useful in providing the required support and adding new functionality to old products through software updates. For instance, Tesla used over-the-air (OTA) software updates in the past to add Auto High Beam feature and Autopilot 2.0 functionality in its cars. Eventually, consumer demands are not only met, these can even be anticipated.

A win-win situation: transformed, meaningful, sustainable products at low cost

A customer-centric decision also means the right financial decision to gain a higher return on investment (ROI). By taking customer insights, manufacturers can save millions on their resulting products as they are able to meet the point-of-demand directly. Even B2B businesses need to understand the needs of the ultimate end-user. According to a press release from Robotics Tomorrow, Aircraft Tooling, a Texas-based repair centre for the aviation industry, has been operating Universal Robots cobots (collaborative robots) in high temperatures and harsh environments for performing metal powder and plasma spray processes for three years without breakdown or service requirements.

Along with usefulness, more and more people are opting for sustainable options. In 2019, Unilever announced that its sustainable living brands were growing 69 per cent faster than the rest of the business and delivering 75 per cent of the company’s growth. To meet its goal of sending zero waste to landfills, Whirlpool uses the IoT and analytics platforms to get information about total waste generated and sustainability performance of its facilities globally.

The road ahead

According to a report from Capgemini Research Institute titled ‘Smart Factories @ Scale,’ China, Germany and Japan lead in adoption of smart factories. In India, Department of Heavy Industry (DHI) and Confederation of Indian Industry (CII) have launched numerous schemes to avoid threats to the domestic manufacturing share and promote smart manufacturing.

SAMARTH-Udyog Bharat 4.0, for example, is one such initiative by DHI under its scheme on the enhancement of competitiveness in the Indian capital goods sector. Most companies that planned to establish smart factories in the nation have been successful.

Schneider Electric launched two smart factories in Hyderabad and Bengaluru in 2019. The factories exhibit how an IoT-enabled system architecture and platform can drive automation and increase operational efficiency while cutting expenses. With a huge population in the country, consumer opinion plays a huge role in large-scale implementation of smart manufacturing in the industry.

Yet, the biggest challenge in any ecosystem remains data security and privacy. IoT systems are vulnerable to security breaches and leaks that raise suspicion among customers. Also, many organisations are afraid to move to newer technologies, platforms and applications. Companies that have invested heavily in on-premises platforms have to cope with the task of moving more functionality to the cloud.

To integrate systems and enable data sharing across them, well-defined standards and protocols are required. Global manufacturers must be aware of legal compliances in different countries where they operate while implementing changes. Talent shortage, especially for data scientist and business analyst roles, is another issue in many places for which reskilling/upskilling is necessary.

In spite of these challenges, smart industries are here to stay. So, if you are not transitioning already, it is time to reconnect with your consumers by hopping on board the Industry 4.0 bandwagon and stay relevant.