According to the European Agency for Safety and Health at Work, the new machinery Directive 2006/42/EC “aims at the free market circulation on machinery and at the protection of workers and consumers using such machinery. It defines essential health and safety requirements of general application, supplemented by a number of more specific requirements for certain categories of machinery.”

Due to increasing use of technology in the development of robots and other manufacturing machinery, there is a significant change in their production processes and the introduction of safe practices is being emphasised. As a result, the machines manufacturers are being encouraged to introduce new technologies, robotic processes, and the use of digital technology with care to safety.

The technological metamorphosis and digitalisation are forcing European mechanical engineering producers to slow down to maintain competitiveness in the global arena. Among the new outstanding technologies in use are advanced production (for example, IoT scales and 3D printers) and advanced resources (including nanomaterials), which is an important step in establishing Assiduity 4.0 or Smart Industry.

In particular, IoT is developing rapidly and steadily. Its use is set to increase in the design and integration of manufacturing facilities and the production of clothing and machinery. Some domestic and foreign companies in the manufacturing sector count on IoT to control and regulate their facilities, increase the transparency of their service (by monitoring integrated performance and so-called prophecy conservation), and strengthen their security measures.

The use of robots in the industry and in addition to robots, bots, androids, and other AI models now seems to be on the verge of inspiring new innovations, making it important for the lawmakers to consider legal and ethical claims, other than those that create a disability in technological development. According to the European Parliament, advances in robots and AI can change living and working conditions and practices, increase efficiency, save costs, increase safety, and improve service conditions in the short and medium term.

In the field of mechanical engineering, attention is focused on AI-guided robots that—while being classified as products or equipment—are to some extent endowed with independent skills and voice learning and apply real-time knowledge, learn from experience, interpret the world, interact with people, borrow new behaviours, and based on their ‘catch’ can operate in an uninhabited environment (similar to construction sites) and move to a visible area automatically, without intervention (and control). In this area, smart machines are always helpful. Mobility can cause more important health and safety pitfalls than those from hollow AI software, because it is possible that a robot, as it moves, could inflict physical damage on humans.

The drive towards this type of delivery in the service sector is now visible and understandable. But it is also inevitably accompanied by critical issues and challenges. It needs to ensure non-discrimination, due process, clarity and understanding of decision-making processes. Attention also needs to be given to the following:

- Results of hiring robots and machine information

- The need for those involved in the development and marketing of AI services to integrate security and ethical aspects from the outset

- To accept the legal responsibility for the quality of the technology produced

- The importance of maintaining quality, autonomy, and individual voice determination, which includes depending on the adherence of the dying robot and relating to the subject of ergonomics

- The acquisition and security of the internet, in relation to the operation and bias that interacts with each other and the site, without any fatal interference and exposure to potential cyber-attacks since many operating processes are now operated by computer systems.

Legal recommendations on AI and machine safety are now in line. The AI Regulation passes the compliance test in Machinery Regulation. The risk assessment of equipment integrating AI systems is done only once in the Mechanical Control Act. Although the proposed AI Regulation addresses the security risks of AI systems, the proposed Machinery Regulation focuses on the secure integration of those systems into machines.

It follows that robots guided by AI systems that fall under the definition of ‘machine’ must also meet the essential requirements of the health and safety equipment regulations and be subject to appropriate compliance testing procedures.

It is questionable how such requirements can reduce certain types of risk. For example, risks may arise from control systems in IoT ecosystems, or lack of familiarity with existing measures to protect human machine interaction in shared work environments. Is it enough to deal with physical damage because of unexpected robot movements, or should mental health considerations should also be included, considering the resulting stress of human and mechanical collisions could be beyond human intelligence in certain areas?

Some of the major points introduced by the proposed Mission Regulations on these issues are mentioned below.

AI systems are ‘high risk’ or ‘potentially high risk?’

The Mechanical Act looks at, among the most risky products, software that performs security functions (including AI systems) and the equipment that integrates AI systems that perform security functions.

Risk assessment should consider changes in the behaviour of equipment designed to operate at different levels of autonomy. Safety functions and settings or rules may not be changed to exceed the limits specified by the manufacturer in the initial risk assessment. Also, in the learning phase, machine behaviour should be limited by appropriate safety circuits.

In addition, in the context of the Essential Health and Safety Requirements (EHSR) operating on mobile devices, specific indicators have been included in autonomous mobile devices and, in particular, automotive vehicles.

Among the various AI-related amendments made during the Mechanical Control Act process, the following four proposed changes are particularly prominent:

- Changing the reference of machine products that introduces ‘high risks’ to ‘potential risks,’ while AI Act provides that AI systems are considered ‘high risk’ if certain conditions are met or arise from a specific list attached to the Regulations.

- Adoption of actions submitted by the Commission for the Amendment of Annexure I within 36 months of its commencement.

- The use of Mechanical Control is limited to AI systems that are self-contained and can occur during normal operation, thus excluding stationary/decryption systems with programmed code to perform certain automated operations.

- Draw up appropriate guidelines that consider the development of AI and equipment to properly assess the additional risks that may arise during the life cycle of a machine.

Cybersecurity and system corruption

Among the new threats, the Regulatory Regulation is turning its attention to cyber-attacks and malicious software, controlling cases of accidental accidents, and instances in which equipment security may be compromised by a deliberate external attack. Keeping this in mind, manufacturers will need to take appropriate steps to ensure that the control circuits performing the security functions are designed to prevent malicious attacks on the system.

With regard to the protection of computer systems from system damage, it is provided that the machine is designed and built so that its contact with something does not cause a dangerous situation. And computer components associated with machine connectivity and/or software access, which are important from a security standpoint, should be adequately protected from potential damage or intent.

The proposal is in line with EU cybersecurity policy and links cybersecurity systems under Regulation (EU) 2019/881 to demonstrate compliance with the Mechanical Law. In particular, certificates or declarations of compliance under the cybersecurity certification system for each Regulation (EU) 2019/881 may be extended to comply with the essential health and safety requirements in terms of the Mechanical Act.

Staff and co-bots: Safety and mental health

Finally, the Mechanical Act discusses the sensitive issue of workplace sharing between humans and equipment and, in particular, between humans and interactive robots or cobots, and the impact that technology can have on workers’ psychological well-being and stress conditions.

Equipment that can learn and change behaviour should be adjusted to interact with people in a positive and understandable way (verbal, gestures, facial expressions, or body movements), telling employees what these plan to do and why. Instead of focusing only on the physical and visual damage that can be caused by AI based machines to humans, the proposal reaches out to control mental health and psychological conflicts that may arise when confronted with a potential and inexhaustible organisation.

Bond

The overall purpose of the security and credit structures is to ensure that all machines, including those incorporating emerging digital technologies, operate safely, reliably, consistently, and with effective remedies in the event of damage. Confidence in these technologies is a business requirement and user acceptance and can encourage competition. There is legal obligation of supply-chain workers (manufacturer, authorised representative, importer, and distributor) in the event of damage caused by robots and equipment integrating AI systems.

The connection between the Mechanical Law and the applicable AI Law is important, with product liability (Directive 85/374/EEC and Consumer Code) and non-compliant national enforcement laws that apply equally. According to current European law on mechanical safety, the responsibility for product safety remains with the manufacturer who puts the product on the market (or the person who makes the major changes to it, according to the Machinery Act). The manufacturer is the one with the most detailed knowledge of the design and production process, therefore, it is placed in the best position to carry out the process of testing compliance.

Some EU safety laws already contain explicit provisions in cases where a few economic operators enter a product before it is put on the market. (The guidelines require equipment manufacturers to provide operator information on how to integrate a device into another machine.) However, clear provisions require a certain level of cooperation among economic workers.

Impact of this regulation in India

The international trade in goods between India and the EU is quite interesting; a great incremental export of machinery from India to Europe is being noticed. Many multinational companies are also manufacturing their products in India for the global market. As an expert certifier of the machinery for CE marking, I came across several MNCs having their headquarters in the EU and other countries with their manufacturing plant located in India. This is because the cost-effective solution is related to the manpower, material, and prompt support.

Since India is one of the potential countries to export various types of machinery worldwide, including Europe, this new regulation is quite important for all the manufacturers who are exporting their machinery to the EU.

EU-India trade statistics

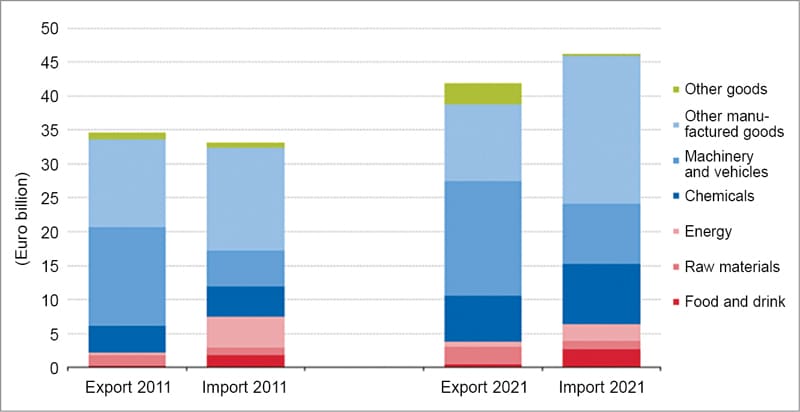

To understand the business potential between EU and India, see the figure on previous page, which has been sourced from Eurostat. Looking at the figures and graph of the manufactured goods, in which machinery is also included as a major product, the trend of export can be seen increasing from the year 2011 to 2021. EU imports of manufactured goods (86%) had a much higher share than primary goods (14%).

According to the statistical analysis, India is the tenth-largest export partner of the EU.

Since India is emerging with the adoption of new technologies, the ‘Make in India’ campaign, and encouragement from the government for drones and robotics machinery, this new regulation is very much essential to understand and align with the necessary compliance requirements.

Mahesh Dave is Technical Director at Trio Technologies and CEO at TuBro Innovative Compliance Solutions LLP. He has global experience of 27 years working at key positions of various Notified Bodies on International Approvals & Global Compliance Requirements