The future of smart recycling is looking brighter. Robots, guided by cameras and artificial intelligence, are helping make recycling facilities run more efficiently.

You must have come across the joke “God created heaven and earth; the rest was made in China.” But, what about the garbage, trash and e-waste; where do these come from? Where does the waste from Indian cities go? Let us find out. This article covers how e-waste is generated, its negative impact on the environment and applications of artificial intelligence (AI) in e-waste management.

If you have been around Ghazipur area in New Delhi and looked up, you would have noticed a mountain. Do not think it is Mount Abu; it is a landfill, a mountain of garbage that has accumulated over the years!

New Delhi has many such landfills at various locations including Narela, Bawana, Bhalswa, Okhla and Ghazipur. The capital city is also home to many other small garbage dumping grounds. Ghazipur landfill is now 65 metres tall, which is only eight metres shorter than Qutub Minar—the tallest minaret of India. The landfill collapsed in September 2017, killing two persons and injuring many others, with cars ending up in the canal. It was a great tragedy. What did we learn from this? Let us delve into it and uncover some facts related to e-waste.

Facts and figures of e-waste

Plastic is present in all electronic products. It is also found in most other things and places. This is where the problem comes in, in the form of pollution. It takes more than 500 years for plastic to decompose. e-Waste, or electronic/electrical waste, includes discarded computers, pen drives, cellphones, televisions and refrigerators. Discarded electronics contain potentially-harmful materials such as lead, cadmium, beryllium or brominated flame retardants.

Generally, e-waste is categorised into five groups based on materials used: ferrous metals, non-ferrous metals, glass, plastic and others. Nearly 48 per cent of the total e-waste is iron and steel, 21 per cent is plastics, 13 per cent is non-ferrous metals including precious metals of which nearly seven per cent is copper.

Problems of trash and e-waste are not only prevalent in India; these are everywhere including the US. The US and China are the two biggest producers of e-waste in the world. Whereas, India is the fifth largest e-waste producer in the world.

Modern industrialisation, population growth and rapidly changing urban lifestyles lead to a myriad of pollution problems including industrial e-waste and garbage that are threatening the lives of all creatures on the planet. In the context of the current industrial revolution, Big Data, big e-waste and big trash are almost synonymous.

e-Waste materials are illegally dumped worldwide. Some reports say that 90 per cent of electronic devices are simply thrown away and mostly end up in landfills, and only 10 per cent of these devices are recycled. Report also says that 70 per cent of the toxicants present in most landfills comes from e-waste. But then, why do I care?

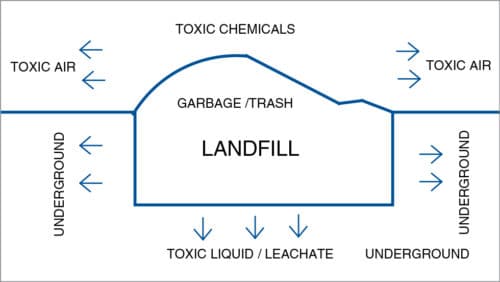

It is a fact that in the region where there is no waste management, apart from various pollutions, diseases are likely to increase. This is because bugs and rats are likely to move in. Improper waste management impacts health and environment through soil, land, water and air. Toxic chemicals from landfills can spread to nearby areas, flow into rivers, emit greenhouse gases and contaminate the water table underground. Landfills create a toxic legacy for future generations. A representation of a landfill is shown in Fig. 2.

Scope of e-waste recycling and management

e-Waste recycling is a multibillion-dollar business. Gold, as well as other precious metals, make up a significant amount of e-waste. Hence, extracting these precious materials from e-waste has proven to be advantageous, especially for the gold industry.

Some people separate different electronic components from e-waste and recycle these for resale. Remaining parts of e-waste, which cannot be recycled or are worthless, are either sent to landfills or burnt (incinerated). Some countries import waste materials to generate electricity. This is because burning waste materials under proper conditions can help produce electricity.

As the old saying goes, “One man’s trash is another man’s treasure.” From the moment you throw waste into the dustbin and it lands up in a landfill, there are huge business benefits involved. Waste management is a lucrative business, and there is a lot of money to be made from waste materials. Waste recycling businesses are managed by waste management giants, including Amazon.

The goal of Zero Waste movement that started around a decade ago is to encourage people to reuse products, so that no trash is sent to landfills, incinerators or the ocean. That is, to save our health and environment, we should try to reduce e-waste, ideally to zero. Sweden has almost zero landfills.

We should try to reduce e-waste, reuse and recycle. As a last resort, only materials that cannot be recycled should be either burned (incinerated) or sent to landfills.

Buying a gadget is easy; you can get it from any shop, but recycling it is not that easy. Hence, product manufacturers should be part of e-waste management. This is where extended producer responsibility, or EPR, comes in. Manufacturers should try to be responsible through the entire lifecycle of the product, including taking back and disposing of the product.

In some countries, citizens have to pay for the waste produced by them. A number of firms have been fined for illegally dumping e-waste materials in public places.

Proper waste management, including e-waste, is required to prevent pollution and health issues. e-Waste management involves the following steps:

- Collection

- Segregation

- Transportation

- Processing

- Disposal/incineration

Waste disposal in a landfill gives rise to land, air and water pollution. An alternative way is to burn/incinerate waste materials under controlled environments. Incineration is carried out both on small and large scales by industries using special incineration equipment under controlled conditions. A waste-to-energy plant is a waste management facility that combusts waste to produce energy.

e-Waste management involves both manual and large, intensive technical processes. e-Waste is first dismantled manually and then sent for further processing. For example, in a laptop, components like capacitors, memories, LCD screen and batteries are first manually removed and separated. Then, the remaining part is sent for recycling through mechanical processing. The mechanical processing plant may include a crushing unit, shredders, and magnetic, eddy-current and air separators.

Burn the shit!

Once waste materials reach landfills, they all look the same and cannot be recycled properly. To get maximum benefit from waste materials, these first need to be sorted properly, either from trash bins or from disposal or recycling stations. Materials collected from trash bins are sent to disposal stations for recycling, incineration or to landfills.

Incineration not only helps get rid of waste, it converts waste into heat and electricity. So, it is advisable to burn materials that cannot be recycled and get the benefits of usable energy and heat while reducing pollution and health hazardous elements. However, this needs to be done under controlled environments.

AI in e-waste management

AI is the new saviour of e-waste management and recycling. AI, machine learning, image processing and robotics have a bright future in the waste management sector.

Two ways to sort waste materials before recycling are either dropping the waste into separate trash bins or letting the trash bins sort themselves through an automatic system.

If everything is dumped into one trash bin, sorting for recycling can be a tiresome task. To tackle this manually, different countries have different colour-coded dustbins for dumping different waste materials. But manual separation of waste materials or throwing into separate trash bin is somewhat confusing as human beings can make mistakes. People can get confused as to where to dump the waste, because they are not sure of the actual material of the packaging and devices. This is where AI comes in.

Employing AI in garbage sorting and disposal processes is a better method for smart recycling and waste management. Therefore AI and various sensors including RFID tags are used. Many intelligent dustbins have been developed that are equipped with AI programs and Internet of Things (IoT) sensors in the waste management sector.

Multitasking sorting AI robots have been developed for waste management that can sort tons of garbage on a daily basis.

In South Korean, RFID tags and sensors are used to collect garbage. A pneumatic garbage disposal system then reads these tags. The main computer, which stores all data, determines an appropriate method to dispose of the waste.

Chinese company Baidu and the United Nations Development Program are working to streamline the recycling of e-waste in China with a new app that can help users sell their old electronics for cash.

Rubicon Global has a cloud-based, full-service waste management and recycling solution. AI and machine learning are incorporated into the solution to enhance human insight and improve waste diversion. The company has also developed an app that uses computer vision to generate a quick assessment of the waste stream, and a device is mounted on garbage trucks to visually analyse roadside dustbins.

As per a report from mirror.co.uk, Bin.E is the world’s first intelligent bin that sorts waste materials. It uses a combination of sensors, image recognition and AI, and can recognise objects like glass, plastic or paper, and compress these before placing them in containers.

Developed by CleanRobotics, TrashBot robot is the first ever smart trash robot that uses AI to sort recyclables from landfill waste.

CP Manufacturing has a complete line of recycling equipment to ensure the highest recovery rates for virtually any material type, including commercial and industrial, e-waste, food waste and green waste recovery. L-VIS is a high-resolution colour camera sorting system from CP Manufacturing that provides accurate colour and size separation of small particles, and is suitable for electronic scrap, plastic flake, metal scrap, glass and other small particle segregation.

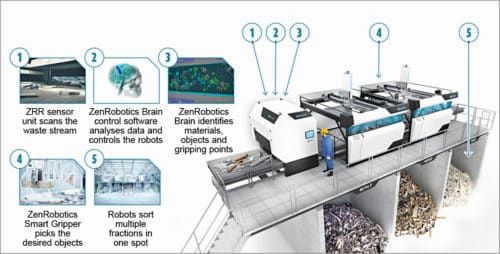

Finnish company ZenRobotics has come up with the world’s first robotic waste sorting system. It employs AI for smart recycling of waste materials. Using computer vision, machine learning and AI, the robot can sort and pick recycled materials from moving conveyor belts.

e-Waste management in India

The government of India has issued revised E-Waste Management Rules 2016, which came into force in October 2016. The Pollution Control Board of India has suggested different colours for different dustbins, namely, green for biodegradable waste, black for e-waste, and blue for plastic and metals. But these dustbins are not used properly due to either ignorance or lack of seriousness of people. Black dustbins for dumping e-waste are rarely found on the streets. So, until now, most of the garbage and e-waste from Indian cities are in landfills or have gone down the rabbit hole.

Absence of strict regulations on e-waste management, lack of awareness by the masses and absence of efficient infrastructure are some factors for the widespread e-waste. Lack of proper procedures for the collection, disposal and recycling are the main reasons for the poor state of e-waste management in India.

India still lags behind other countries when it comes to an automated waste management system. Recently, many Indian companies have started working on e-waste management and recycling solutions. These include Namo e-Waste, Revive Electronic Waste, Attero Electronics, Let’s Recycl, Karo Sambhav, Cerebra and E-Parisaraa.

India ranks third in the world in terms of high-quality research publications in AI. However, currently, implementations of AI and machine learning in e-waste management on a large scale are hardly seen here. Current e-waste management systems are unable to efficiently deal with the massive amounts of e-waste generated every day. Automating the processes of sorting and disposal using AI and machine learning would help in handling e-waste more effectively. It is time to switch to AI and machine learning for smart recycling and e-waste management in India.

To sum up

Our lack of initiative in e-waste management has resulted in many recyclable precious items being thrown into dustbins, which have ended up in landfills. It is the need of the hour to reduce, reuse and recycle e-waste. Gold, silver and other precious metals can be obtained by recycling e-waste. Non-recyclable items can either be sent to landfills or burned (incinerated) under controlled environments.

We can expect a significant decrease in e-waste if traditional techniques are replaced with automated intelligent solutions and sorting AI-robots. As sensible individuals, we should reduce e-waste and make others aware of its value, in addition to the harmful effects of e-waste. This is important to save our lives and the environment.