Automated Warpage Analysis For Hardware Designs

As validation cycles tighten, engineers are revisiting how warpage and stress are simulated across complex assemblies and real production geometries.

Vinci has announced the availability...

AI-RAN Digital Twin Testing

Hardware-in-the-loop setup combines ray tracing, full 5G stack and AI inference to test next-gen RAN features entirely inside the lab.

Rohde & Schwarz and NVIDIA...

3kW Supplies Gain Three-Phase Input

Compact 3 kW programmable AC-DC power supplies gain a new wide-range three-phase input variant that widens voltage compatibility and broadens deployment options across demanding...

Bio-Semiconductor Memory Boost Electronics

Penn State engineers fuse synthetic DNA and perovskite to build ultra-efficient memristors that could shrink power use and supercharge data processing for future electronics.

Pennsylvania...

Capacitors For EV On-Board Chargers

These capacitors support EV on-board chargers, handle high current and voltage, last long, and provide reliable performance for electric vehicle charging systems.

TDK Corporation has...

JOB: Firmware Bluetooth Developer At MosChip In Hyderabad

APPLY HERE

Location: Hyderabad

Company: MosChip

Required Skills

Firmware Development: Nordic nRF, Qualcomm CSR, Silicon Labs, STM, ESP32

OS development: Linux, Android

Protocols: Bluetooth, BLE, BLE Mesh, Wi-Fi, Ethernet, SPI,...

JOB: Senior Field Applications Engineer At Arrow Electronics In Bengaluru

APPLY HERE

Location: Bengaluru

Company: Arrow Electronics

What You’ll Be Doing

Familiarise with the latest technologies in FPGA and Acceleration domains like AI/ML by attending supplier trainings in...

“We Aim To Establish R&D Presence And Deliver “Made For India”...

Edge AI demands devices that can think locally and act instantly. In an exclusive interaction, Muneyb Minhazuddin and Jerome Gigot from Ambarella tell EFY’s...

JOB: Principal Engineer – Hardware At Microchip Technology In Chennai

APPLY HERE

Location: Chennai

Company: Microchip Technology

This engineer would be part of the Secure Computing Group (SCG) Applications Engineering team in Chennai India, working on microprocessor...

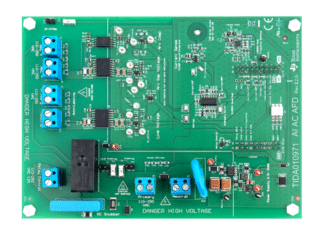

AC Arc Fault Detection Reference Design For Circuit Breakers

Arc faults can pose a serious threat to electrical safety, but detecting them can be challenging. This reference design integrates fast current sensing, voltage...