A connector may seem to be a relatively unimportant component when we first look at any device. But design engineers know the importance of choosing the right connector for their design. A connector is the base of an electronic product, as it binds the entire system together. Also, it plays a key role in the successful design and reliable operation of an embedded system.

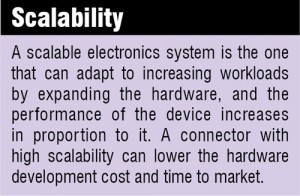

Interestingly, knowing better about the connectors enables us to choose an ideal match for our application. It is easy to design an optimal product by doing this in the early stages of an embedded system design process. It could make our system smaller, lighter and easier to handle. It also helps reduce cost and increase usability.

How connectors have changed

Just like other electronic components, connectors are also available in thousands of variants. Specifications and dimensions range from connectors for the smallest IC to big power connectors carrying very high current values on board.

With respect to the embedded connectors, a lot of changes have been witnessed over a couple of years. And on the design side, a vast majority of modifications have been implemented in response to consumer electronics trends.

Symmetry. The trend of symmetrical connectors was started by Apple, with the creation of lighting connectors for their branded portable devices. This trend has seemingly caught on. Apple has recently announced a new USB type-C connector, which is a reversible variant, which means there is no ‘wrong’ way to connect it. You can connect it upside down and it will still work.

Miniaturisation. The ongoing requirement for portable equipment is continuing to drive the general miniaturisation trend. To remain competitive and cope with an increasing demand for smaller circuits, connector manufacturers have further decreased the size of their connectors.

But despite their smaller size, the miniaturised connectors are engineered to still be able to pass large currents that were previously handled by their bigger predecessors. However, smaller electromechanical components have a problem of breaking easily.

The line dividing smaller connectors and fragile connectors. Manufacturing technology evolved to accommodate ruggedness to tackle the problem of fragility with reduced size. For instance, the housings are made from heat-resistant, self-extinguishing thermoplastic material in cases where environmental sealing is required.

More robust connectors can easily resist very harsh environments for a longer period of time. Considering the ease of servicing, pluggable connectors with higher ingress protection (IP) rating and better locking features have also come up. The connectors are also designed to be easier to connect, using technology such as ‘push-in connection’ that gives the connector an integrated spring lever.

Connectors also have features implemented to improve stability. For instance, TE Connectivity’s Power Triple Lock line features two optional locks—connector position assurance which secures the connector to remain intact and engaged, and terminal position assurance which prevents the terminal from backing out while ensuring that contacts remain fully seated in the connector.

High-power connectors combine high conductivity and ultra low resistance. They are provided with air-cooling mechanisms to reduce heating effects. The increasing usage of optical fibre connectors in high-bandwidth applications is now demanding newer and quicker termination technologies.

Connectors going contactless. An interesting technology that came up in the connector space in the last two years was the concept of contactless connectivity. This technology meets the market need of miniaturisation, decentralisation and the need for smarter systems. It allows you to transfer power and data without signal loss or the need for mechanical coupling through messy connection cables. It can operate through water, oil and non-metallic barriers, and is immune to pollution, vibration and harsh environment. It has low maintenance cost.

Hybrid technology. Hybrid connectors combine both power and data signal elements into a single housing. You can replace them with a single hybrid connector unlike traditional designs where you have to use separate data and power connections. They are widely used outdoors in heated and dusty environments and also under special IP compliances such IP65 and IP66.

Hybrid connectors are commonly used in avionics and also in video recorders for security surveillance. Combining power and data communication on a single connector helps reduce the number of connector elements, bill of materials (BOMs) and the size of the entire system, though this is subjective—varies for each case.

Hermaphrodites and stacking connectors. Conventional connectors are of two varieties: male-ended and female-ended. A female-ended connector cannot be replaced with a male-ended connector and vice versa.

In the case of new hermaphroditic or genderless connector, it has mating surfaces that include both male and female aspects simultaneously, that is, it has a ‘mate to itself’ design. This feature removes the gender constraints and allows these components to freely connect with others, provided they are of similar size and type. The hermaphrodite connectors are also informally called as androgynous, sexless, combination, combo, two-in-one and two-way.

The stackable connector systems have an array of male pins on one surface and a complementary array of female sockets on the opposite surface. This allows stacking of multiple units.

Factors to consider for selecting the best connector

Connectors for embedded systems can be of two types based on the application or the type of transmission they allow—power or data. You have to know whether they would be used on a printed circuit board (PCB) or in a harness assembly. Another typical division is based on whether they are input connectors, on-board connectors or output connectors. The main consideration for choosing a connector would be the end application of the embedded computer.

There are multiple criteria based on which a connector can be chosen depending upon its application.

In case of the input and output (I/O) connectors, the main parameters to look at are size and number of I/O signals required for your design, amongst other things.

For coaxial radio frequency (RF) connectors, the frequency range and attenuation levels are what matter the most.

For power connectors, the factors that have more emphasis are voltage ranges, current ranges and operating temperatures the connector can withstand.

The connectors used in aerospace and defence industries require safety, security and ability to withstand harsh environments. More rugged types of connectors, which cannot be easily bypassed, are the kind required here. Other properties, such as material science, also vary depending upon several technical and commercial factors.

Compactness and portability. The size and weight of a device can be an important factor in certain application fields. If the dimensions of the product forbid the designers to use a particular type of connector, they might have to go for a non-standard way of using different interfaces on it.

Miniaturisation and portability requirements are very high on consumer electronics end. The size of PCB is becoming smaller and the design of connector is also changing accordingly.

Another area where compactness and portability issues come up is the avionics sector. On devices such as unmanned aerial vehicles (UAVs), vibration form factor, the size, height and weight are very important criteria. The overall electronics used in UAVs are bound to be very small in size, and that is when portability of connector becomes a key aspect.

The industrial requirement for embedded systems would not maintain so much of miniaturisation or portability issues. In that case, the designer can afford to use bigger connectors since there are no major constraints in terms of compactness.

Significance of interoperability/compatibility. Another important aspect for designers is whether the connector supports interoperability and, if yes, with how many components or devices. If the given connector is compatible with products from three or four different vendors, the user can buy a connector made for the device for one brand and match it with the device of another brand. But a user needs to look into such prospects under worst-case scenarios.

When it comes to the manufacturing side, there are a lot of lead time and production issues. So the manufacturers have to look at the possibilities for replacements that can be used for a product in manufacturing.

Previously mentioned industry standards, such as USB and HDMI, help ensure intermateability of connectors.

Longevity. Longevity of a connector is generally defined by its insertion (and removal) cycles and gives an idea of how long it is expected to work properly. Insertion cycles are defined in the datasheet of each connector. Consider a connector with an insertion cycle of 200. Under normal conditions, you can insert and remove the connector approximately 200 times and still expect reliable performance. After that, the behaviour is not predictable.

For devices such as cellular phones, where we plug in the connector once or twice daily, the insertion cycle and longevity are expected to be greater.

Longevity depends on vibration aspects too; what wear and tear the product faces throughout its life cycle.

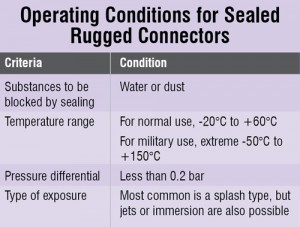

Environmental factors. The designer should keep in mind all the possible environmental conditions under which the device could be operated by the user, and accordingly ensure that the connectors and cables can withstand these. For example, in case of fire or heat exposure, one should ensure that the connectors are of proper fire retardant (FR) grade. Sealed connectors are commonly used in such rugged environmental conditions.

Availability and serviceability. “Use of expensive or out of the ordinary connectors makes it difficult to service and satisfy customers,” says T. Anand. But according to Gagan Shah, the product specialist of Phoenix Contact, “The selection criteria for connectors should not be based on the price. It is important to understand the need and application area of the customer before providing the right connector solution. Sometimes with additional cost the customer can get more benefits which cannot be achieved with low cost solutions.”

The serviceable points of connectors should have proper detachment mechanism. Some connectors are pluggable while others are directly soldered to the board. Using pin headers, wherever possible in the design, ensures ease of servicing.

Speed, capacity and other factors. Another criterion for selection of connectors is based on the kind of performance they can handle in terms of speed and response time. Choose connectors based on the standard ratings of voltage/current capacities and wire gauges they offer.

Determining the peak capacity is important as, if the device reaches peak consumption or has a current burst, it may no longer work reliably. The connector manufacturers typically define the specifications very clearly in their datasheet. If the tolerances are within the range of the particular component, the user will not have performance issues.

Grounding and shielding are necessary requirements for EMI/EMC, RF, grounding, power and signal separation and many data-critical applications. Having snap-fit or locking sockets is another critical need for continuously or frequently moving devices. We now have double lock and triple lock facilities for connectors. The security standpoint can also be a factor—whether or not anybody can easily bypass into the communicated signal.

Standards to be fulfilled. Having appropriately certified cables and connectors (such as CE, UL and ISI) is a mandatory requirement for professional designs. Regulatory requirement such as Restriction of Hazardous Substances (RoHS) directive also needs to be fulfilled. In certain specific fields of application, like in the case of military uses, connectors used may require a specification such as MIL grade.

USB, HDMI, D-subminiature and/or DIN are the standards to be complied by I/O connectors for serial communication, modular jacks, audio jacks and RCA connectors.

Zero insertion force (ZIF) connectors can be used as on-board connectors for display modules or cameras, rectangular shrouded/unshrouded connectors, external cables and for testing and programming purposes.

Additionally, in some embedded systems for special applications, high-speed back-plane connectors, microprocessor and memory chips sockets and standard memory or SIM card connectors would also be required.

Though very rarely seen, sometimes there also exist a set of geo-specific standards defined by countries or regulations. They insist on using a specific type of connectors for specific applications.

The author is a dancer, karaoke aficionado, and a technical correspondent at EFY. Find her on Twitter @AnuBomb.

nice information…I am a newbie wants to select few connectors for my embedded project…where stepper motors, servos, switches, bad sensors are used…can you suggest me connectors for such project..?