With success rates in both simulated and real-world environments, the research promises to alleviate human workers from repetitive tasks, redefine precision in robotics, and pave the way for the future of automated manufacturing.

Integrating semi-autonomous and autonomous robots into real-world industrial environments is expanding, promising to revolutionise manufacturing processes by assisting human workers. These robots are designed to take over repetitive tasks, thus reducing the physical strain on human workers and increasing efficiency. Robots could significantly contribute to two critical areas: object grasping and product assembly. Implementing robotic systems in these areas is fraught with challenges, primarily due to the intricate programming required for specific tasks, which can take time and effort.

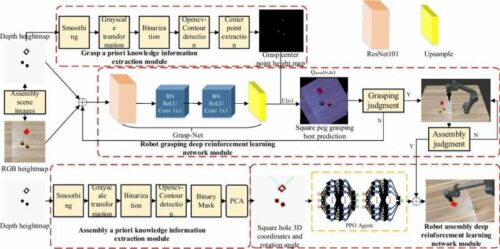

Qingdao University of Technology researchers aim to address these challenges using deep reinforcement learning. The research team, led by Chengjun Chen and Hao Zhang, has developed a framework that leverages deep reinforcement learning for autonomous grasping and assembly skill acquisition in robots. This framework includes a deep Q-learning algorithm for grasping skills and a Proximal Policy Optimization (PPO)-based algorithm for assembly skills, enhanced by prior knowledge to optimise actions and minimise training data and time. These advancements are built upon recent computer vision and machine learning developments, enabling robots to learn and improve their object grasping and assembly abilities efficiently.

The researchers also designed specific reward functions to accurately evaluate the robots’ performance, focusing on grasping and assembly tasks. The effectiveness of this new training approach was tested in simulations and real-world settings, utilising UR5 robotic arms equipped with RealSense D435i cameras for object recognition. The results were promising, with the algorithms achieving a high success rate in grasping and assembly tasks across simulated and physical environments. The grasping success rate reached 90%, while the assembly tasks showed a success rate of 86.7% in simulations and 73.3% in real-world tests under specific conditions.

This groundbreaking research demonstrates the potential of deep reinforcement learning in industrial robotics and opens the door to more efficient robot programming, potentially transforming manufacturing processes. Looking forward, the Qingdao University of Technology team plans to refine their algorithms further, aiming to enhance their system’s accuracy and efficiency in real-world applications.