A team of researchers from Ohio University has designed a smart wind sensor that could enhance the performance of drones in everyday life.

Image credit: Frontiers in Materials

With the increase in unmanned aerial vehicles (UAVs), the need for enhancement in terms of safety and efficiency is also increasing. To meet these requirements, researchers from Ohio University have designed a new anemometer with upgraded, next level wind sensors.

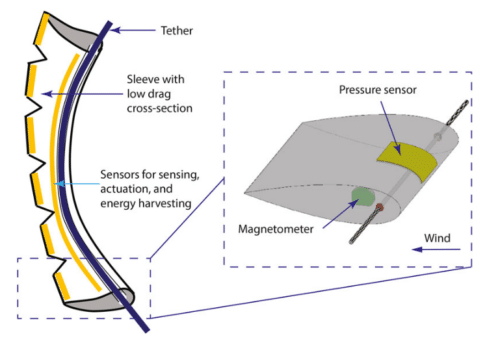

The newly developed anemometer is designed like an airplane wing which contains a series of sensors integrated to it. These sensors help with detecting the speed of the wind and the direction through the movement. Wind speed is detected via a dual layer of capacitive pressure sensor along with polyvinylidene fluoride (PVDF) diaphragm. The PVDF has a piezoelectric property which generates voltage under pressure, which can be used to detect wind speed. The 3D digital magnetometer senses the wind direction and helps with identifying the orientation of the airfoil with respect to the earth’s magnetic field.

The PVDF diaphragm puts its piezoelectric property at use by reacting to every change in pressure. These changes in the air pressure create voltage change in the film’s reactions which are used to measure wind speed.

These PVDF anemometers are expected to make a difference in the current drone technology. The current anemometers like pitot tubes are unsuitable for smaller UAVs as they consume higher power. Also, the signal processing with these patio tubes is complex and expensive. This creates the need for a change in the existing model and design.

The newly developed PVDF anemometers are expected to fill this gap and increase the safety and efficiency of the UAVs.

“These are very advanced materials, and they can be used in many applications,” Marcelo Dapino, study author said. “We would like to build on those applications to bring compact wind energy generation to the home.”