University of California San Diego engineers have developed versatile, wireless, and battery-free electronic “stickers” designed for confined spaces to measure force between objects.

Inherently, humans can detect force, facilitating our smooth interaction with the environment and aiding clinicians in conducting intricate surgeries. Equipping electronic devices and medical implants with the force-sensing capability could revolutionise various sectors.

University of California San Diego engineers have crafted electronic “stickers” capable of gauging the force between two objects. These stickers are wireless, battery-free, and designed for confined spaces, making them adaptable for various uses. These applications range from granting robots tactile sensation and enhancing the realism in VR and AR experiences to boosting the intelligence of biomedical tools, ensuring industrial equipment’s safety, and refining inventory management efficiency in warehouses.

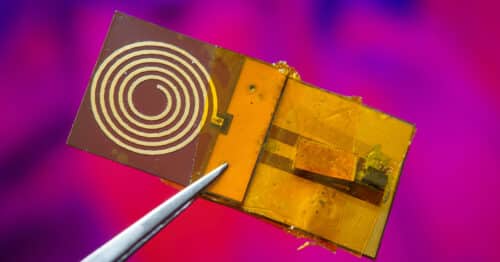

The force stickers, primarily built from a tiny capacitor and an RFID sticker, work like a barcode readable wirelessly through radio signals. Ingeniously designed, they measure and transmit force data to an RFID reader. When force is applied, the capacitor’s polymer compresses, causing its copper layers to converge and increase its electric charge. This change in charge alters the RFID signal, which an external reader interprets, quantifying the force applied. This method of modulating the RFID signal facilitates a compact design, starkly contrasting to older methods requiring much larger components. Moreover, the RFID sticker operates efficiently on low power through backscattering, adjusting incoming signals from the reader based on the capacitor’s changes and reflecting them for interpretation.

The researchers developed two force sticker versions. One, made with a very soft polymer, was used in a model knee joint experiment, where it precisely gauged varying forces applied on the joint. The other, made with a harder polymer, was trialled in a warehouse setting and, when attached to a box’s underside, effectively measured the weight of diverse items within. These force stickers proved resilient in tests, enduring over 10,000 force applications with consistent accuracy. Plus, they’re economical to produce, with each sticker costing under $2, as highlighted by the researchers.

The force stickers work best in stable settings, not dynamic ones. The researchers are addressing this and aim to make the stickers smartphone-compatible, eliminating RFID readers.

Reference: Agrim Gupta et al, ForceSticker, Proceedings of the ACM on Interactive, Mobile, Wearable and Ubiquitous Technologies (2023). DOI: 10.1145/3580793