Ball-shaped camera to put 360° photography on the map

Ever since hardware entrepreneur Jonas Pfeil first started working on Panono camera, a ball-shaped device that captures photo spheres, back in 2011, the field of 360° imagery has exploded.

The Panono captures photos when thrown upwards, taking the shot at the moment it reaches its highest point. The 360° images it captures are technically 108MP, stitched together from the array of 3MP lenses that dot the exterior of the ball.

The camera is about the size of a grapefruit and feels just as heavy. The plastic exterior is sprinkled with small, slightly indented lenses, and it has a rubberised green trim, which provides a better grip. On one of the ball’s poles there is an LED and a trigger button; on the other is a cap that covers the micro-USB port and connector for a removable handle. The handle is for situations when you do not want to throw the camera; simply attach it and click the button on the grip.

Electronic skin sensors to control mobile gadgets

A skin-worn sensor that turns the human body into a touch-sensitive surface for controlling mobile devices has been developed by scientists in Germany. Named iSkin, the sensor is made from bio-compatible silicone rubber with pressure-sensitive sensors that are stuck to the skin of the users, allowing them to use their own body to control mobile devices.

Developed by scientists at Max Planck Institute for Informatics and Saarland University, the experimental system has been produced in different shapes and sizes to suit various locations on the body, such as the finger, forearm or behind the ear-lobe. It is capable of detecting touch input pressure even while being stretched or bent. With the current prototypes, wearers can answer incoming calls, play music and adjust volume.

The base material is poly-dimethyl-siloxane (PDMS), an easy-to-process silicone based organic polymer. Conductive carbon black powder is added to the liquid silicone before it is spread flat by a thin-film applicator. After creating the tattoo-like designs on a computer, a laser cutter traces out the design, which makes up the sensor. It is then sandwiched between two clear sheets of silicone. The stickers are attached to the body using a medical-grade adhesive that can be easily peeled off after use, without hurting the skin.

Insect-sized robot can jump on water

Researchers from Harvard University have built an insect-sized robot that mimics the way water striders jump on water. By observing water striders using high-speed cameras, scientists noticed that insects do not simply push down on the water but gradually accelerate their legs so as to not break surface tension. Striders also sweep their legs inwards before each jump, to maximise the amount of time they touch the surface, which increases the force of their pushes.

The researchers used these principles to develop an ultra-lightweight robot with a 2cm-long body inspired by origami. Its 5cm-long wire legs are curved at the tips like a real water strider’s and coated with a material that repels water.

A flea-inspired jumping system, called a torque reversal catapult, launches the robot from the surface of the water up to 14.2cm in the air.

A lamp that runs on a glass of water, salt

A Philippines based company has developed a lamp that can run for eight hours at a stretch on a glass of water and two tablespoons of salt. The Sustainable Alternative Lightning (SALt) lamp does not have any hazardous material or component and it has a USB port for charging a smartphone.

According to SALt website, “There are more than 7000 islands in Philippines and most of these do not have access to electricity. We want to eliminate the sustaining cost in areas that rely on kerosene/battery-powered lamps and candles as their main source of lighting.”

The lamp uses the science behind the galvanic cell, the basis for battery-making, changing the electrolytes to a non-toxic, saline solution, hence making the entire process safe and harmless.

When electrodes are placed in the electrolyte, the energy generated kicks an LED light into gear. Moreover, the salinity of ocean water can operate the lamp.

Stronger, tougher paper could lead to flexible electronics

Cellulose fibres can be used to make tougher and stronger paper that may pave the way for flexible electronics such as paper smartphones, printable solar cells and green vehicles.

Researchers at University of Maryland, USA, have discovered that paper made of cellulose fibres is tougher and stronger the smaller the fibres get. They explored the mechanical properties of cellulose, the most abundant renewable bio-resource on Earth, and made papers with several sizes of cellulose fibres, ranging in size from 30mm to 10nm.

The paper made of 10-nanometre-thick fibres was 40 times tougher and 130 times stronger than regular notebook paper, which is made of cellulose fibres a thousand times larger.

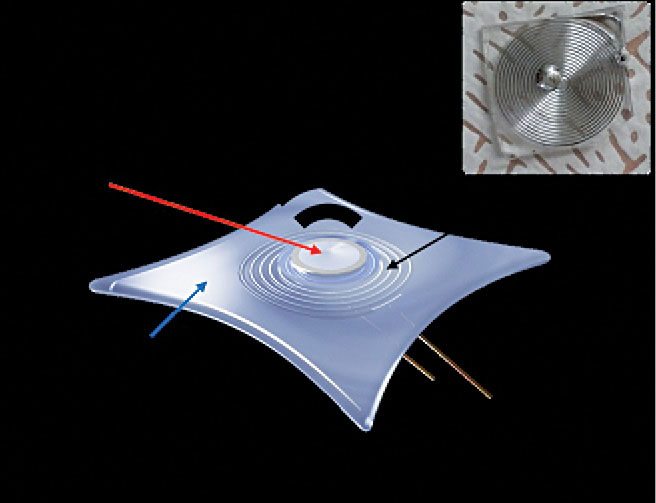

Bendy liquid metal coils for making stretchable loudspeakers

Coils of liquid metal could be used to make stretchable loudspeakers and microphones, potentially leading to new kinds of hearing aids, heart monitors, and wearable and implantable devices.

Acoustic devices often rely on rigid metal coils that can both emit and detect sound. Scientists in Korea have created a stretchable acoustic device by replacing this rigid coil with a deformable, liquid metal coil. This new coil is made of Galinstan, a highly conductive liquid metal alloy of gallium, indium and tin. They used a syringe to inject Galinstan into a spiral channel in a thin film of flexible silicone rubber. They then attached copper wires to the end of the coil and a neodymium magnet (made from an alloy of neodymium, iron and boron) to the centre of the coil.

They operated the device by electrically charging the liquid metal coil, turning it into an electromagnet that could push back and forth off the neodymium magnet to either detect or emit sound. They were able to record sounds, such as the human voice and a beeping alarm clock, and play these back while the device was attached to the wrist or was being stretched by hand.

Researchers found the device can be stretched up to 50 percent its length, 2000 times without any noticeable loss of acoustic performance. It could also play back sounds across the frequency range of human hearing.

Wood based computer chips could help with electronic waste crisis

Wood based computer chips are a reality, and these could make the recycling of electronics a much simpler task. Developed at University of Wisconsin, USA, by a group led by engineering professor Zhenqiang (Jack) Ma, the wood-derived computer chip is made by processing wood into nanocellulose paper, which is then used as a substitute for silicon.

Unlike the rigid silicon wafer that serves as a plate for transistors in most computer chips, Ma’s chip uses a translucent, bendable plate made of highly processed wood. According to a piece in the MIT Technology Review, using nanocellulose in lieu of conventional silicon requires just a tiny fraction of the semiconducting material otherwise needed in the process, and does not sacrifice performance.

In two demonstrations, Ma and his colleagues showed they could use nanocellulose as the support layer for radio frequency circuits that perform comparably to those commonly used in smartphones and tablets. They also showed that these chips could be broken down by a common fungus.

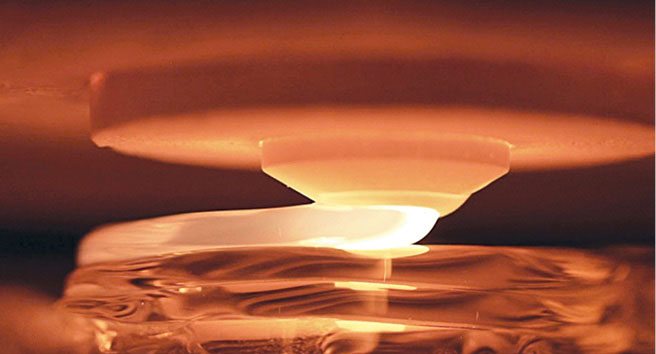

MIT unveils 3D printing of glass objects

The field of 3D printing is still largely the domain of major companies in need of easier prototyping methods and hobbyists. But a new breakthrough could vastly expand the technology’s applications, that is, 3D printed glass.

MIT has unveiled a method it calls G3DP that allows the creation of complex 3D glass structures to be printed in a similar fashion to plastic constructs.

MIT’s process accomplishes this by using two chambers, one that acts as a kiln cartridge and another that works to melt the structures together. The molten glass is distributed through an alumina-zircon-silica nozzle that pours the material out like soft-serve ice cream.

The G3DP process was developed by a team including MIT Media Lab’s Mediated Matter group, MIT Glass Lab, Wyss Institute and MIT’s Mechanical Engineering Department.

One of the project’s researchers, Neri Oxman, says that this could also lead to advances in creating fibre-optic cables that transmit data more efficiently.

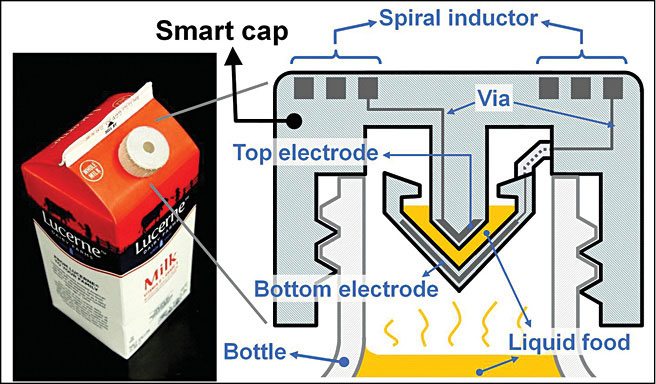

3D-printed smartcap to sense spoilt food

UC Berkeley (USA) engineers, in collaboration with colleagues at Taiwan’s National Chiao Tung University, are expanding the already impressive portfolio of 3D printing technology to include electrical components. They have put the new technology to test by printing a wireless smartcap for a milk carton that can detect signs of spoilage using embedded sensors.

Polymers and other such materials are poor conductors of electricity, and thus bad candidates for electronic devices. To get around this, the researchers started off by building a system using polymers and wax. They then removed the wax, leaving hollow tubes into which liquid metal—in their experiments they used silver—was injected and then cured.

Researchers integrated the electronic components into a plastic milk carton cap to monitor signs of spoilage. The smartcap was fitted with a capacitor and an inductor to form a resonant circuit. A quick flip of the carton allowed a bit of milk to get trapped in the cap’s capacitor gap, and the entire carton was then left unopened at room temperature for 36 hours.

The circuit could detect the changes in electrical signals that accompany increased levels of bacteria. The researchers periodically monitored the changes with a wireless radio-frequency probe at the start of the experiment and every 12 hours thereafter, up to 36 hours.

Facebook’s solar-powered drone to beam Internet from the sky

Facebook has completed the production of its first full-scale solar-powered Internet drone that will deliver wireless Internet with lasers from the sky in parts of the developing world where there is a lack of connectivity.

Mark Zuckerberg, co-founder, Facebook, has announced the completion of Aquila, Facebook’s first unmanned plane that beams down Internet connectivity from the sky, as part of his project with Internet.org.

Aquila’s wings are made of carbon fibre. It has the wingspan of a Boeing 737, but weighs less than a car and can stay in the air for months at a time.

Facebook will have lasers on the ground that can locate the dome-shaped optical head, located on the bottom of the plane, in the air, basically shooting a laser at a dime-sized target that is more than 16km (10-miles) away. The plane will first hone in on the general location of the laser on the ground, proceeding to target it further and lock onto the location so that it can start beaming down the Internet.