A recent study reveals that waste polyurethane foam may be used to produce highly effective EMI shielding material. It is covered by carbon nanotubes by hot pressing them.

Image Credits: American Chemistry Society

Electrical circuits generally release electromagnetic signals and electromagnetic interferences that disrupt the functioning of the nearby devices. The traditional EMI shielding materials like aluminum, silver and copper does not minimize the electromagnetic pollution.

Several studies over the past years on developing EMI shielding materials using polymeric materials have yielded positive results. These EMI shielding materials are highly flexible, weigh less, and have excellent capacity for absorbing these electromagnetic waves. However, these conductive polymeric composites segregate during hot pressing. This segregation results in instability of the shield and even collapses the structure.

Polyurethane foams are polymeric materials used extensively in seating, mattress, and more as they are cheap, versatile and highly elastic. These polymeric materials are dumped in large numbers as wastes and researchers have found a new way to recycle them efficiently.

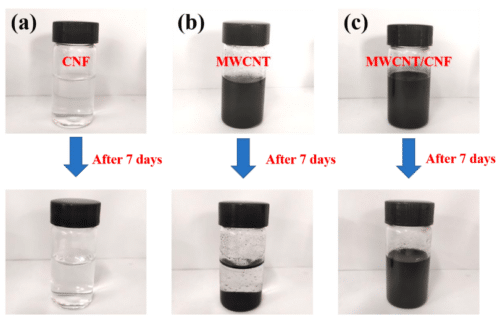

The polyurethane foam is an effective EMI shielding material as it forms a skin-core separated structure while hot pressed. Multiwalled carbon nanotubes (MWCNTs) were distributed in an aqueous solution of cellulose nanofibers (CNFs). Then, this mixture was dip-coated upon the surface of polyurethane foam. Here, the conductive MWCNT/CNF sheet acts as the skin and the nonconductive waste polyurethane acts as the core.

The MWCNT at 6.6 wt% enables the polyurethane foam to achieve maximum conductivity. The EMI shielding effect demonstrated by the waste polyurethane foam was significantly greater than any of the previous materials. It displayed adequate dependable EMI shielding and flexibility. It maintained a strong EMI shielding effect even after 1000 cycles of bending and mixing. Researchers expect the polyurethane EMI material to exhibit greater efficiency and sustainability when compared to other EMI materials.