Using energy responsibly is the essential factor for innovations in the field of energy efficiency towards a greener planet. Infineon Technologies AG, the market leader for power semiconductors, is continuously investing and innovating in future proof semiconductor technologies and solutions, enabling environmentally friendly applications as well as performance and ease of design.

The EZ-PD BCR (Barrel Connector Replacement) is a highly integrated USB-C controller, together with the USB-C connector, it replaces barrel connectors, custom connectors or legacy USB connectors in electronic devices. The EZ-PD BCR solution supports the USB Power Delivery (PD) standard that interoperates with all USB-C power adaptors without the need of firmware development. The recently published Revised Radio Equipment Directive from the European Commission proposes to standardise charging ports for most electronic devices with an aim to reduce e-waste from retied, incompatible chargers. The proposal calls for USB-C as the common charging port and it allows consumers to charge their devices with the same USB-C charger, regardless of the device brand. A common charging standard harmonises fast charging technology and prevents product producers unjustifiably limiting the charging speed when using a charger from a different brand. The common charger proposal also unbundles the sale of a charger from the sale of the electronic device such that consumers will be able to purchase a new electronic device without a new charger. This will greatly limit the number of unwanted chargers purchased or left unused, and ultimately reduce e-waste. “Infineon is committed to provide its customers with solutions that enable them to leapfrog ahead their competition in performance while contribute to a greener future,” says Adam White, Executive Vice President and Chief Marketing Officer in the Power & Sensor Systems Division at Infineon.

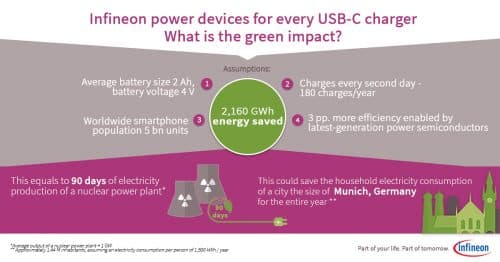

“Our end-to-end solution in the USB-C charging domain provides the best performance, the highest system reliability and also meets contemporary ecological requirements: it is energy efficient and aims to reduce e-waste. The disposal of retired chargers is responsible for eleven thousand* tons of e-waste every single year. This has to change and we at Infineon are ready to support this change. Our power semiconductor portfolio includes discrete and integrated state-of-the-art silicon and next-generation gallium nitride products which can cover any design requirements our customers may have.”

Changing to a USB-C charging port using EZ-PD BCR at the power-sink holds numerous benefits for the consumers as well as the manufacturers. It offers higher levels of convenience to consumer by being agnostic to connector types or product manufacturers when selecting a charger. Manufacturers can benefit from the consolidation of large variants of chargers to a standard USB-C charger. EZ-PD BCR minimises BOM (bill of material) cost for the USB-C power-sink system and it guarantees USB-C specification compliance and interoperability through USB-IF certification. At the power-source, in the charger, the latest CoolGaN Integrated Power Stage (IPS) 600 V leverages the markets most reliable GaN and driver technologies, uniting

ultimate efficiency and reliability with ease-of-use. GaN technology allows for higher switching frequency and more output power in the same size or smaller charger with

the same power level. An integration results in very high power density making this device the first choice for fast charger designs. CoolGaN has an advanced breakdown field of ten times and an electron mobility of two times higher compared to silicon devices. The key for the high frequency operation capability of CoolGaN lies in a ten times lower output and gate charge, compared to silicon-based devices and a reverse recovery charge of virtually zero. Besides the positive environmental impact, consolidation through standardisation and resultant manufacturing cost savings make the shift a favourable option also to manufacturers.