The entrepreneurial study, “Entrepreneurial India”, conducted by the IBM Institute for Business Value (IBV) in collaboration with Oxford Economics, revealed how more proactive engagement between start-ups and established organizations can help start-ups harden their business models, accelerate growth and leapfrog into the big leagues.

Many start-ups fail as they overlook fundamental business issues and try to grow the business or launch their product too quickly. Investors, stakeholders and design engineers all want to see rapid growth as proof that they have found a great idea, but there is a vital balance to be struck.

Many start-ups fail as they overlook fundamental business issues and try to grow the business or launch their product too quickly. Investors, stakeholders and design engineers all want to see rapid growth as proof that they have found a great idea, but there is a vital balance to be struck.

Launching an unreliable product because corners are cut to allow an earlier launch can be financially disastrous for large companies, who may have to invest huge sums of money as they try to repair their reputation. Start-ups, however, will rarely survive such events.

Product designers in start-up companies therefore need access to support to help navigate the exciting yet critical milestones in bringing their ideas to life, particularly to ensure they conduct adequate and thorough testing. Whatever the design process, an iterative approach with regular testing, is the most sensible way to progress a product design.

Understanding the value of test and the implications of not testing

Any designer working on a project wants to be the first to capture the market and stave off the competition, so time to market is critical, but at what cost? Entrepreneurs can often fall into the trap of budgeting to hire a sales team, and forgetting all about testing. Although sales teams are necessary, without enough budget set aside to test new products adequately, the sales team might not have a product to sell.

There is a huge difference between the designs that are successful on paper and how that product behaves when someone can feel it, touch it and put it to the test. All these devices are made from individual components which have their own individual tolerances and parameters and even with careful attention, stack tolerances can quickly cause a design to fail with the right combination of boundary components. Whilst the initial five or ten products off the production line may function as expected, testing helps design engineers to find these and other unanticipated problems when production is scaled, especially if components are operating on the edge of their tolerance.

What does healthy testing look like?

The growth of embedded software-based products means the focus on testing to find and fix problems is even more critical. Even though many of these products use off-the-shelf hardware, the complex nature of the software, especially in IoT, industrial and healthcare industries, requires a well-planned testing regime.

The benefits of a healthy testing strategy include the development of a more robust product that is truly market ready, reduced development costs from finding faults early and a reduced time to market as the design phase is more efficient.

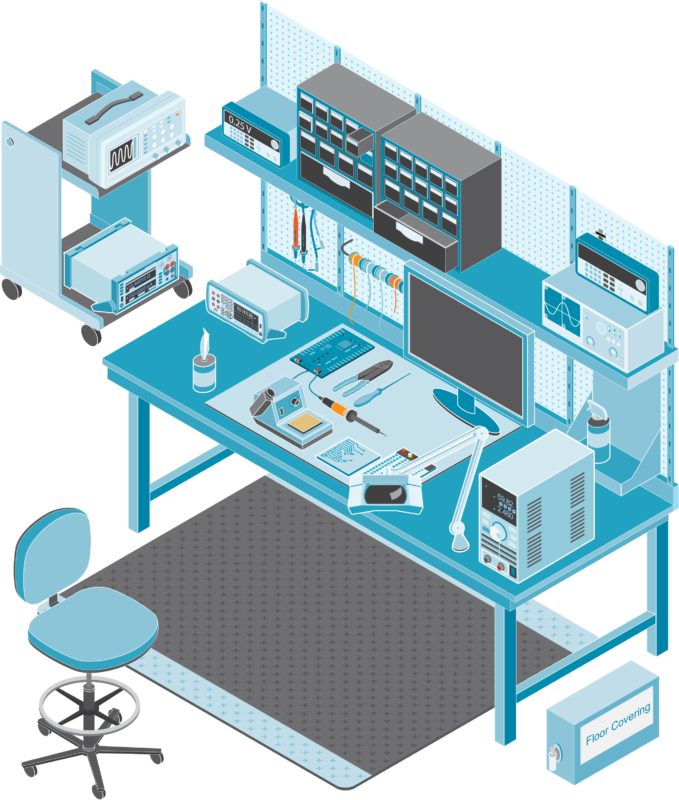

One of the main components to a successful testing strategy is having the right tools to test. Investing in high quality testing and measurement tools will pay dividends, as they can be used across the product lifecycle, from research through to development and beyond.

What are the obstacles to test?

Whilst the case for testing is clear, there are challenges that start-ups often struggle to overcome.

Expertise:

With the rapid expansion of new technologies over recent years, one of the big challenges for designers in early-stage companies is knowing what and how to test for each of the technology demands.

Designers in today’s world are under pressure to be experts in every field, which is impossible. Wireless power, for example, is a technology that many designers may be required to implement in future designs. This means that designers must know how to not only design a wireless power system, but also test for multiple parameters they have never encountered before. Unless they have expertise in this field of design, proper testing of items like foreign object insertion, may cause a product design flaw that might not be discovered until it’s too late. This challenge is particularly evident when designing a product for use in regulated industries such as healthcare, as products are required to be tested to meet strict regulatory requirements and meet strict industry standards. Obtaining the necessary certification is difficult, and especially so for start-ups who may be unfamiliar with the processes.

Cost:

The cost of testing can also be a significant obstacle for start-ups. Tools and the time taken to test both require significant investment, and sometimes account for a large proportion of the initial manufacturing cost, but the investment is worth making. Finding a suitable partner, for example, a high-service distributor such as element14 provides start-ups with access to experience alongside a broad range of testing tools which specifically suit the needs and budgets of different sized businesses and start-ups. Rather than buying individual tools, for instance, mixed domain tools allow designers to test for a variety of requirements using one multipurpose integrated tool, which is more cost effective. The increased use of USB-based tools also provides a major advantage for start-ups, as they allow access to multiple tools but at a lower cost.

To help address the knowledge gap with new technologies, designers need to partner with companies that have the expertise, experience and support and guide them through the necessary processes. Thankfully there are options available to start-ups, as some organisations have services which address the needs of start-ups and help bring their designs to life.

As we can see, testing does present challenges but the benefits far out-weigh the cost and time required, particularly for start-ups. Failure to test can result in catastrophic consequences and start-ups are particularly vulnerable. Fortunately, there are solutions to make testing and measurement accessible for design engineers, and by working with an experienced industry partner such as element14, designers can be sure of the expertise, tools, support and guidance needed to make their designs and indeed their new business a success.