A biosensor is an analytical device that converts a biological response into an electrical signal. The term biosensor is often used for sensor devices used to determine the concentration of substances and other parameters of biological interest even where these do not utilize a biological system directly.

With an estimated 60 percent annual growth rate, the major demand for biosensors is coming from the healthcare industry, but with some pressure from other areas such as food-quality appraisal and environmental monitoring. The current types are potentiometric and amperometric biosensors and colourimetric paper enzyme strips.

However, all main transducer types are likely to be thoroughly examined, for use in biosensors, over the next few years.

Which of the Features Are Required for a Successful Biosensor?

A successful biosensor must possess at least some of the following features:

- The biocatalyst must be highly specific for the purpose of analyses, be stable under normal storage conditions and show good stability over a large number of assays.

- The reaction should be as independent of such physical parameters as stirring, pH, and temperature as is manageable.

- The response should be accurate, precise, reproducible, and linear over the useful analytical range, without dilution or concentration. It should also be free from electrical noise.

- The complete biosensor should be cheap, small, portable, and capable of being used by semi-skilled people.

Besides, there should be a market for the biosensor. There is little purpose in developing one if other factors encourage the use of traditional methods and discourage decentralization of laboratory testing.

How Biosensor Works?

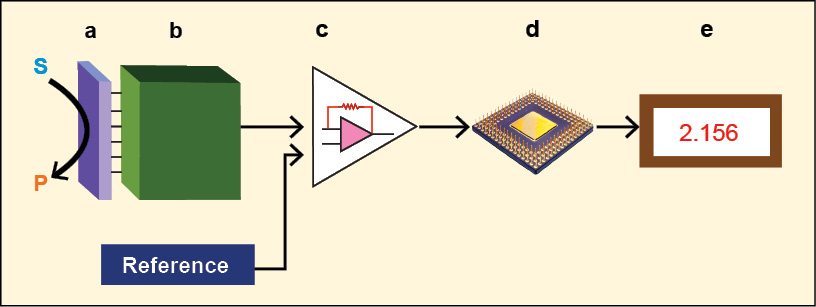

The key part of a biosensor is the transducer (shown as the green box in Fig. 1), which makes use of a physical change accompanying the reaction, which may be:

- The heat output (or absorbed) by the reaction (calorimetric biosensors)Changes in the

- distribution of charges causing an electrical potential to be produced (potentiometric biosensors)

- Movement of electrons produced in a redox reaction (amperometric biosensors)

- Light output during the reaction or a light absorbance difference between reactants and products (optical biosensors)

- Effects due to the mass of reactants or products (piezoelectric biosensors)

There are three so-called generations of biosensors-

First-generation biosensors are those in which the normal product of the reaction diffuses to the transducer and causes an electrical response.

Second-generation biosensors involve specific mediators between the reaction and the transducer in order to generate an improved response.

Third-generation biosensors are those in which the reaction itself causes the response and no product or mediator diffusion is directly involved.

An electrical signal from the transducer is often low and superimposed upon a relatively high and noisy (that is, containing a high-frequency signal component of an apparently random nature, due to electrical interference or generated within the electronic components of the transducer) baseline.

The signal processing normally involves subtracting a reference baseline signal, derived from a similar transducer from the sample signal, amplifying the resultant signal difference, and electronically filtering (smoothing) out the unwanted signal noise.

The relatively-slow nature of the biosensor response considerably eases the problem of electrical noise filtration. The analog signal produced at this stage may be output directly but is usually converted to a digital signal and passed to a microprocessor stage where data is processed, converted to concentration units, and output to a display device or data store.

Advantages

- Rapid, continuous measurement

- High specificity

- Very less usage of reagents is required for calibration

- Fast response time

- Ability to measure non-polar molecules that cannot be estimated by other conventional devices

Applications

- Monitoring glucose levels in diabetic patients

- Food analysis

- Environmental applications

- Protein engineering and drug-discovery applications

- Waste-water treatment

Future Prospects

Trends in biosensor technology over the past 30 years have taken this equipment from a simple and cheap component to the integration of several sensor systems into one unit including multiple components, making these systems smaller and tailored for mass production. The vision for the biosensor industry is to create micro-scale technology that will be suitable for performing sample preparation, analysis, and diagnosis all with one chip.