Yes, if you are unable to find your hearing aid, you can simply print it using a 3D printer and, within minutes, you will have a new device. 3D printing has evolved much beyond even recreating something as complex as a hearing aid. In a first-of-its kind procedure, doctors in Britain have created a prosthetic face for a man because the entire left side of his face had to be removed since it was cancerous. Doctors first tried plastic surgery; however, that did not work since the patient was also undergoing chemotherapy and radiotherapy.

The doctors then scanned the left side of the patient’s skull and used information technology to develop a new face. 3D printing was used to create layer upon layer of nylon plastic, with the exact elements that were required in the face reconstruction procedure. Dental surgeons have been using 3D printing since the last few years to create identical models of patients’ jaw bones so that they can explore the different surgical processes available to them, prior to a surgery or tooth extraction.

The US President bets on 3D printing

On 12th February, President Barack Obama, in his State of the Union address, talked of ways to revive the US manufacturing economy. He mentioned 3D printing as the possible panacea that could multiply manufacturing opportunities. Here is an excerpt from his speech: “Our first priority is making America a magnet for new jobs and manufacturing. After shedding jobs for more than 10 years, our manufacturers have added about 500,000 jobs over the past three years…..

“Last year, we created our first manufacturing innovation institute in Youngstown, Ohio. A once-shuttered warehouse is now a state-of-the-art lab where new workers are mastering 3D printing, which has the potential to revolutionise the way we make almost everything. There’s no reason this can’t happen in other towns. So tonight, I’m announcing the launch of three more of these manufacturing hubs, where businesses will partner with the Departments of Defence and Energy to turn regions left behind by globalisation into global centres of high-tech jobs. And I ask this Congress to help create a network of 15 of these hubs and guarantee that the next revolution in manufacturing is ‘Made in America’.”

What is 3D printing all about

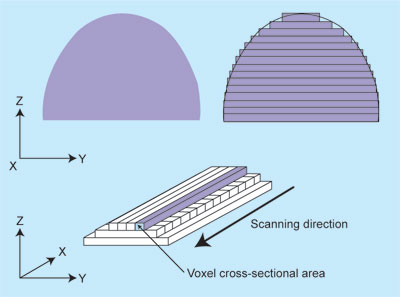

3D printing, also known as additive or rapid manufacturing, is a process wherein a three-dimensional solid object of just about any shape can be created from a digital model. The starting point is a digital computer aided design (CAD) file, developed with a 3D modelling program, or scanned into a 3D modelling program with a 3D scanner. The software cuts the design into several hundreds or thousands of horizontal layers to form instructions that the 3D printer understands.

The 3D printer then processes these instructions and creates each layer as per specifications. As the layers are made, they are combined together in a seamless manner and, finally, a 3D object is created. Autodesk is one of the leading players involved in creating software for 3D printing.

While conventional manufacturing involves subtractive processes, that is, removal of material by chiselling, cutting, etc, 3D printing is based on an additive process, where successive layers of material build different shapes. Objects are created by means of a sequential layering process. 3D printing technology is being used to make jewellery and footwear, in industrial design, architecture, engineering and construction, as well as in the automotive, aerospace, dental/medical, education, geographic information systems and several other industries.

Several companies are using 3D printing. For example, the global sports shoes manufacturer, Nike, uses 3D printing to develop multi-coloured prototypes of shoes. This has brought down both the cost and time spent in prototype development for Nike, considerably.

Let us understand the modelling part first. Additive manufacturing works on virtual blueprints from CAD or animation modelling software, and ‘slices’ them into digital cross-sections so that they serve as a guideline for the printing to be done. Depending on the printer used, a binding material is deposited on the build bed or platform until the material/binder layering is complete and the final 3D model has been ‘printed.’ It is a WYSIWYG process where the virtual and the physical models are mostly similar. The STL file format serves as a standard data interface between CAD software and the machines. It estimates the shape of a part or assembly using triangular facets. Smaller facets produce a higher quality surface. PLY is a scanner generated input file format, and VRML (or WRL) files are frequently used as input for 3D printing technologies that are able to print in full colour.

The printing machine understands the design via a .stl file and lays down consecutive layers of powder, liquid or sheet material, i.e., whatever is needed to make the model from a number of cross-sections. Thereafter, these layers, which are in line with the virtual cross-sections from the CAD model, are either connected together or automatically fused to make the desired shape. The key advantage of this technique is its ability to make just about any contour or form.

The printer resolution defines the layer thickness and X-Y resolution in dpi (dots per inch), or micrometres. On an average, the thickness is about 0.1 mm. However, some printers such as the Objet Connex series and 3D Systems’ ProJet series can print layers as thin as .016 micrometres.

The time taken for model construction using contemporary methods ranges from a few hours to a few days. The actual time taken would depend on the method used, and the size and complexity of the model. Additive systems can bring down this time to a few hours depending on the nature of machine used, and the dimensions and quantity of the models being created simultaneously.

While conventional techniques, such as injection moulding, cost less for manufacturing polymer products in large numbers, 3D printing is speedier, more flexible and also cheaper when the number of units is low. The greatest advantage is that design and concept development teams have the freedom and power to produce parts and concept models using their own desktop-size printer.

Choosing a 3D printer

To start with, a firm needs to determine whether a 3D printer is really required or not, i.e., whether using a service provider would be better or would owning a 3D printer lead to higher productivity, lower costs and quicker delivery. 3D printing is a solution that takes care of all the modelling and prototyping needs of an organisation. Another purpose that 3D printing serves is that of confidentiality—especially with a new design, since blueprints or CAD designs do not go out of the company at all. How you intend using the 3D printer will determine what type you buy. For instance, if you plan to use the 3D printer in the concept development stage for product design and for design validation, you should go in for a high-speed full-colour printer with labelling options. Test-driving the printer’s control software will tell you how easy or difficult it is to send .stl files to the 3D printer.

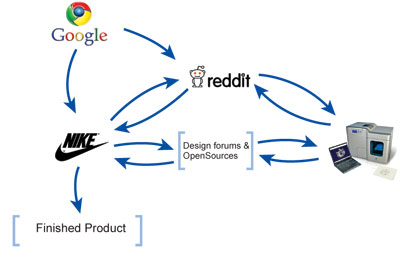

Apart from commercial printers, personal 3D printers are also available. And there are both fully assembled and DIY models. One can use the free version of applications such as Google SketchUp and the Blender program with them. Imagine if you and I begin using 3D printing—each of us could ‘manufacture’ something. Today, customers expect a higher level of customisation and personalisation, which 3D printing can facilitate through the concept of mass collaboration. Websites such as Wikipedia, Reddit, etc, are geared up to ‘mass collaborate.’ Reddit is a website which includes various sub-reddits. These sub-reddits enable members to share special interests.

The free software (the starting point in the above diagram) has been developed by Google. A company like Nike is in a position to enlist particular communities that have an interest in design and fashion, as well as access to a 3D printer. Via mass collaboration, people can come together to create new designs and send them to Nike. Personal 3D printers are becoming affordable and free software is also available. This means that home users now have the resources to develop prototypes. This could bring down unemployment and, yes, maybe you can also reinvent your house in a cost effective manner.

Living on the moon: The future of 3D printing

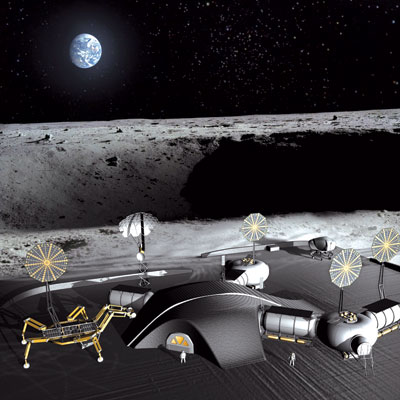

Living on the moon could become a reality with 3D printing. An entire moon base could be printed using lunar dirt as raw material. A team from The European Space Agency (ESA) is working closely with architects to chalk out ideas for a 3D-printed moon colony. The whole idea is to design for extreme climates and exploit the environmental benefits of using local, sustainable materials—just as it is done on Earth.

Using material that exists on the moon would mean there is no need for large and expensive spaceships to transport materials from Earth. The moon base would be built using a robotic printer moving over an inflatable dome. The base would have hollow walls and a cell-like robust structure that looks like the skeleton of a bird. This would guard humans residing on the moon from gamma radiation and small meteorites. ESA and its partners have simulated building some portion of the base that weighs about a ton using a blend of silicon, aluminium, calcium, iron and magnesium oxides. This is similar to the composition of moon dust. The 3D printer is being run in conditions identical to those on the lunar surface, i.e., the 3D printing is being done inside a vacuum chamber.

The future

Perhaps the evolution of 3D printing could mirror that of photo printing. When printer prices dropped and became affordable, people started printing their own photographs, in the comfort of their homes.

Currently, most people do not print their photos at home. Rather, they actually pay for printing services from high-quality speciality print shops on special occasions. The same scenario may emerge in the case of 3D printing. People will invest in 3D printers as they start to become affordable. Eventually, as 3D print technology becomes omnipresent, users will start approaching specialised shops in order to get quality that stands out from what can be achieved at home. We already have a few companies such as Shapeways, Kraftwurx, Freedom of Creation, etc, that deliver online 3D printing services in both the B2C and B2B space. Customers will upload their 3D designs to the company website, the designs would then be 3D printed using industrial 3D printers and delivered to the customer.

So if you get that 3D printer, you know you can actually do a lot more than just printing your lost hearing aid.

The author is currently associate professor at the School of Management Sciences, Apeejay Stya University