Most MSMEs and startups consider designing and manufacturing as two separate processes, which is not correct as these are interdependent. There are many aspects to be considered in manufacturing and it cannot be left to assembly houses who neither have the proper equipment nor the capacity. Good EMS partners can ensure fulfilment, where the EMS partner does everything from components procurement to delivery of the finished product to customers.

Most startups and MSME electronics companies focus on designing a product and do not have a proper plan for manufacturing the product. This is partly because most electronics manufacturing service (EMS) partners want a deal size of a million dollars and above, which the startups and MSMEs usually do not have at the beginning. This forces them to get the PCBs assembled through assembly houses and do rest of the product manufacturing themselves.

However, electronic product manufacturing is an intense process that needs careful planning and interaction with the manufacturing team from the design stage itself. The PCBA-only assembly process blinds the startups and MSMEs who do not spend enough time and effort on the manufacturing aspects. But, as the production volumes increase, they start realising that they can no longer manage the production and they start looking for EMS partners to outsource it.

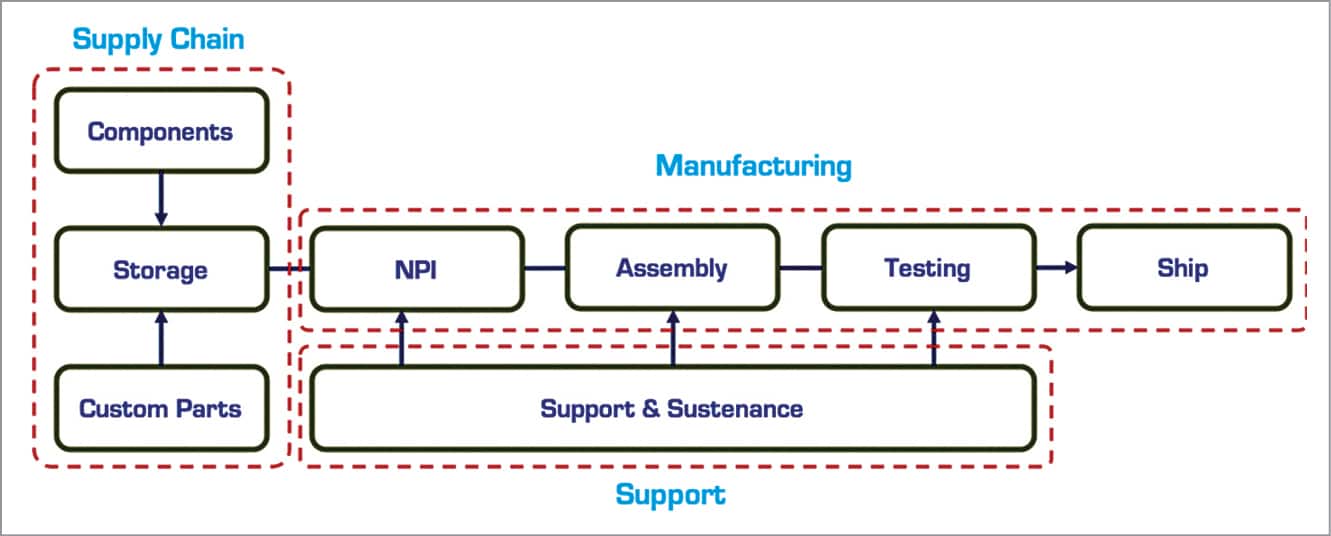

Unfortunately, this simple throw-it-over-the-wall approach neither helps the product owner nor the EMS partner. To understand the issues involved in electronic product manufacturing, let us try to see what happens inside an EMS partner’s premises. Please see Fig. 1, which shows the following three discrete blocks of activities:

- Supply chain

- Manufacturing

- Support and sustenance

Supply chain is the first element that impacts the product’s success. It deals with the electronic components, custom parts (mechanical, plastic, electronics, etc), their quality, and their storage in the plant (we will see why storage is key a little later), all of which play a vital role.

Next is the actual manufacturing phase, which covers new product introduction (NPI), board and system assembly, testing of the PCBAs, and the final product (including calibration). Shipping is also important, as a product delivered in a damaged condition can result in customer dissatisfaction and expensive replacements or repair.

The final element is the product support. It covers both warranty and post-warranty repairs, obsolescence management, customisation of products for the global market, and global manufacturing.

These aspects show how important and intense the manufacturing is. It is not just the assembly of PCBs.

Why manufacturing is critical

Good manufacturing ensures a reliable long-lasting product. But for a successful product, it has to be designed such that the manufacturing line can easily adapt to the design. This is easier said than done. While startups and MSMEs focus on design and cost, they miss out on crucial manufacturing.

With increased use of surface mount technology (SMT) parts, automated assembly and manufacturing is inevitable. This essentially means the PCBs and the systems have to be assembled by contract manufacturers (EMS partners) who invest in automated lines and do manufacturing as a service. This outsourcing imposes some ground rules for successful product manufacturing.

Let us have a look at the rules for better understanding:

1. The main process is the procurement of components and how these are stored. Sourcing components from an established distributor or a vendor is the most critical aspect, which is rarely followed. While buying components from local/unauthorised sources for the prototype may be fine, for bulk production these have to be procured from authorised sources.

2. Electronic components, in general, have an affinity for absorbing moisture. While for parts like transistors and diode-like items the impact of moisture is less, IC packages suffer the maximum damage. Generally, ICs that have absorbed moisture crack open during reflow soldering due to expansion of water vapour inside the package, leading to a damaged board. In addition, raw PCBs also absorb moisture, but EMS vendors bake the boards in an oven to ensure the PCBs are moisture-free. Absorption of moisture essentially forces the components to be stored in a dry environment and dehumidified storage space. Only established vendors have this facility as this type of storage is expensive.

3. Post storage, when the product gets into assembly line, there are three critical steps that decide the yield (good or bad) in the manufacturing line. However, the yield is decided by the design and is not a parameter that can be controlled by the EMS partner alone. For good PCB soldering, right quantity of solder, right component positioning, and right test access points are important. What complicates the issue is the dependence on the type of manufacturing equipment used by an EMS partner.

To make the whole manufacturing process reliable and productive, almost all EMS partners have their own design guidelines and checklists to ensure high quality and good yield.

These are called their DFx guidelines, where x stands for assembly, manufacturing, and testing.

The first guideline is a checklist known as DFM (design for manufacturing) process that defines the footprints of the components and how they are oriented. Typically, DFM has to be addressed early on during the PCB design stage itself. The DFM guideline ensures the right amount of solder is used for perfect reflow/wave soldering.

The second guideline is DFA (design for assemmbly), which ensures the components are located properly so that the pick and place machines place the parts 100% accurately. Also, aspects like multiple PCBs in one large PCB (known as paneling), tooling holes, and PCB silkscreens for legible reading are ensured.

Third and the most important is the DFT (design for test) guideline. It ensures proper testing of the assembled and soldered parts (PCBAs, subsystems, and final products). When the production volumes are high, EMS partners recommend in-circuit testing (ICT).

This testing essentially accesses all the nodes in the PCB and tests the interconnections and the components.

Remember, ICT rarely tests the functionality of the system. This essentially means designers need to plan for the final product’s testing. Also, in most cases, they need to design the functional testers (automatic test equipment known as ATE) too to test the product and also help in calibration if the product has any measurement function.

Another key aspect that designers leave unaddressed is the product packing for shipment. A well-designed product can be damaged in transit if the product shipment package is not designed properly. It Is seen that the product shipment packaging is never addressed and it gets attention only when customers report damaged product.

Startup entrepreneurs and MSME owners should address the issue of manufacturing as an integral part of the design process and design the product in consultation with the EMS partners. This means identification of EMS partner is crucial and needs to be done early in the product development phase.

Also, check the practical guide to Faster Product Development.

Some examples

To exemplify the importance of manufacturing here are two real-life examples. The first is a test & measuring equipment designed for a battery manufacturing line to measure cell voltages during the battery manufacturing process. This equipment records the readings through wireless connections into the cloud (both Wi-Fi and Bluetooth). Since each batch has 100 cells, each cell has to be monitored individually.

The company that supplied the equipment had developed a coin-size unit connected to every cell. They had supplied the first batch of 200 units for trial. While the software (both cloud and firmware) was working properly, the readings were inconsistent. The issues ranged from intermittent working to wrong readings. The battery vendor who had been doing this manually was desperate to have the solution working.

On investigation, it was found that the boards had not been soldered properly, leading to the components changing their characteristics (the design also had flaws with low-accuracy parts). Above all, there was no provision for calibration, which lead to the wrong readings.

After 6-8 weeks of struggle, the battery manufacturer called off the trials and even today continues with manual measurements.

The second example shows how a wrong assembly can fail the product for compliance standards. An OEM AC-DC power supply was selected for integration into our product. After integrating the PSU into our design, we took the product for compliance testing. The product failed in the conducted emission test consistently.

We finally called the PSU OEM as our experience told us that conducted emission failures are typically due to power supply related circuits. The PSU OEM opened and found that the 220V AC lines were connected as two individual wires. They just twisted the phase and neutral wires and the problem disappeared. Later we discovered that they had told our design team about this, but our design team had failed to inform the manufacturing team.

What needs to be factored in

The key to successful product development is to have a holistic view of the overall process. It is important that the EMS partner is selected and brought on board early on in the development process to ensure that the design is manufacturable. The processes followed by big EMS are extensive and they invest a lot in these processes. But many MSMEs and startups work with Tier 2 or Tier 3 EMS vendors, who may have limited capacity and are typically just assembly houses.

Large EMS vendors typically do what is known as fulfilment. When we choose this mode, EMS partner does everything from component procurement to final delivery of finished product to the customer. Tier 2 and Tier 3 vendors do not offer this, so when you work with them you have to plan and implement the design covering the aspects needed for the manufacturing.

This approach helps but may not solve the issue completely. For example, an ICT tester will cost $200,000 to $300,000, and the 5D XRAY equipment for BGA soldering inspection costs close to $300,000. Designers have to understand the machines that their manufacturing partners have and implement the design accordingly. This means the design teams have to know the manufacturing process well and plan to complement the skill that is not available in the EMS partner’s line.

Points to keep in mind

Electronics product manufacturing is a vast topic, which is also dependent on the design. Every electronic product is unique, and the manufacturing needs to align with that. While giving an exhaustive list of points to note is out of the scope of this article, here are some key points that are important.

- Evaluate the EMS partner based on your product’s need and match them. For example, if your product uses lots of magnetics, an EMS vendor who can make them inhouse will be preferable to an EMS vendor who buys it from other vendors.

- If your product is medical or avionics related, the EMS partner should have relevant certifications and also IT and other infrastructure (for example, medical devices manufacturing needs sterilisation facility and Clean Rooms).

- Empanel EMS partners who use manufacturing machinery from established manufacturers.

- When transitioning the design to the manufacturing line, give robust training for the product and ensure everyone involved in the product’s manufacturing is trained.

- Continuously monitor the product’s manufacturing performance like test process yield, assembly yield, obsolescence, and custom parts performance.

S.A. Srinivasa Moorthy is Director Engineering Design, D4X Technologies Pvt Ltd