The sun blesses the earth with enough energy in one hour—4.3×1020 joules—to fulfill all of our energy needs for a year (4.1×1020 joules). Its giant bombardment of free and non-carbon-emitting energy has impelled scientists for decades to develop photon-electron converter solar cells that catch sunlight and convert it directly into electricity.

Silicon solar cells are in use since the beginning of the space programme and now dominate the industry, with worldwide shipments of solar products expected to have totaled $41.9 billion in 2016. Silicon solar cell technology has captured 90 per cent of the solar market, but scientists around the world are working to find a way to make them more efficient, affordable, stable and reliable.

The typical silicon wafer solar panel is power rated using sunlight at zenith (climax or high point), which provides a radiance of just over one kilowatt per square metre at sea level. This radiant energy comprises 445 watts of visible light component, 527 watts of IR radiation and 32 watts of UV radiation. Wafer-type silicon solar cells available today can process only visible sunlight. Thus 56 per cent of the available energy to be converted into electricity is unutilised with silicon solar cells.

The pursuit of lower-cost and more efficient solar cells has led to the search of new materials. In the past several years, several emerging photovoltaic technologies were the focus of R&D effort in the academia and industry. These third-generation solar cells do not require custom-made, high-priced, complicated processing equipment, as also expensive silicon or rare earth elements such as indium.

According to National Renewable Energy Laboratory (NREL), which is an international organisation for certification of solar cell efficiency, multicrystalline silicon cells are 21 per cent efficient and expensive, while single-crystal silicon cells have efficiency of around 25 per cent. The highest efficiency of 46 per cent has been recorded for gallium arsenide-based multijunction solar cells but at excessively high cost. The bright CIGS photovoltaic cells are 22.6 per cent efficient. One of the potential application of these solar cells was envisaged for window glasses. Thin films of semitransparent photovoltaic modules used in place of window glasses on a building will allow people inside to see through the window while appearing as tinted glass from the outside.

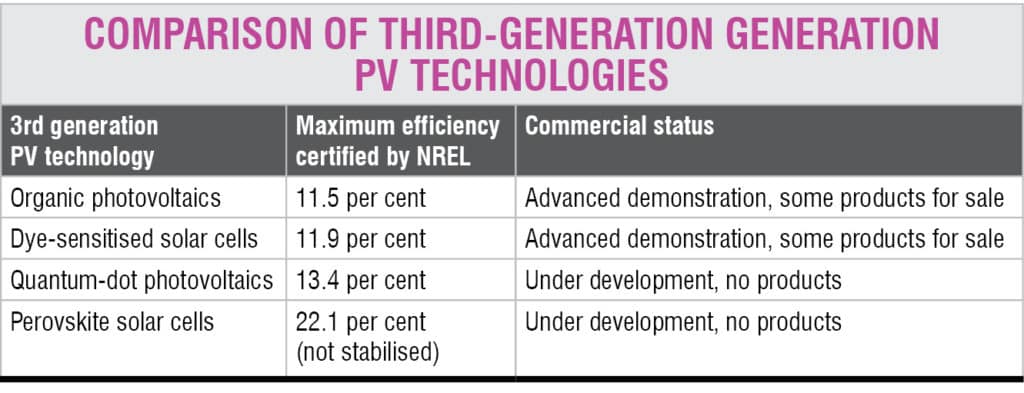

The promising emerging photovoltaic technologies, called third generation PV, are organic photovoltaics, dye-sensitised solar cells, perovskite photovoltaics and inorganic quantum-dot solar cells. Unlike traditional silicon solar cells, these represent transformative technologies with great potential for extremely high-throughput manufacturing at very low cost, low environmental impact, mechanical flexibility and molecular tailorability while using non-toxic, earth-abundant materials with short energy payback times. This makes them suitable for applications beyond rooftop and solar-farm panels. The fundamental advantage of these thin-film technologies comes in the form of the amount of material required for fabrication.

However, the lower price advantage of these emerging photovoltaics is offset by their lower efficiency. The power conversion efficiency (a ratio of light energy in to electrical energy out) of dye-sensitised solar cells, organic photovoltaics and quantum-dot cells today sits at roughly 12 per cent. Hence these emerging photovoltaic technologies are applicable only in niche markets that require light weight, flexibility and variable-angle performance, such as in consumer electronics. Some are still being developed by technology incubators and start-up companies. Thus today photovoltaics market is dominated by silicon-photovoltaics.

The two metrics for evaluating and comparing different photovoltaic technologies, in conjunction with their power conversion efficiency, include:

1. Levelised cost of energy (LCOE)=Total life-cycle cost/energy produced

2. Energy payback time (EPBT) =Energy consumed over the life of the module/Energy generated over its lifetime

Fortunately, these two metrics predict bright future for the new emerging technologies.

Conventional silicon cells require ultra-high-purity silicon—of the order of 99.999 per cent pure. These cells are made using energy-intensive crystal growth and vapour deposition methods. One of the drawbacks of silicon technology that further increases its cost and limits applications is that silicon is indirect band semiconductor, so it doesn’t absorb sunlight strongly. Therefore relatively thick layer of silicon is used in cells, which become brittle and hence have to be supported on a rigid, heavy piece of glass. A silicon solar cell requires 14 steps to manufacture, including preparations requiring the use of high-heat, expensive automation and clean rooms.

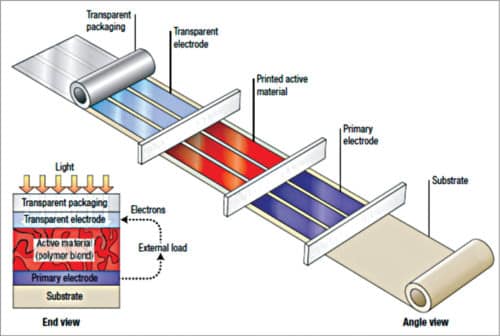

In comparison, the new emerging photovoltaic cells are made from low-cost materials, including organic polymers, small molecules and various types of inorganic compounds, and can be fabricated on flexible supports via inexpensive solution-phase techniques common in plastics manufacturing, such as high-speed roll-to-roll printing. In addition, these PV cells use 1000 times less, light-absorbing material than silicon solar cells, which further reduces their cost.

Third-generation solar cells

Organic photovoltaics

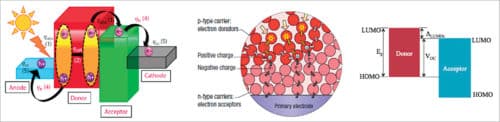

In organic photovoltaics, bulk heterojunction structure (a mixture of donor and acceptor materials in a bulk device) is most commonly used due to its high efficiency and compatibility with low-cost manufacturing techniques such as inkjet printing, spin coating and roller casting. These PVs are renowned as high-PCE polymer-fullerene solar cells.

When the light incident on an organic solar cell passes through the transparent anode to the donor, the photon is absorbed at the donor layer (based on the generalisation that the organic donor is the light-absorbing material). The charge carriers are generated by photo-induced electron transfer. An electron is excited from the highest occupied molecular orbital (HOMO) to the lowest unoccupied molecular orbital (LUMO), creating a bound electron-hole pair known as an exciton. The exciton diffuses to the donor-acceptor interface. There, the excited electron is transferred to the LUMO of the acceptor, and the energy difference between the LUMOs of the donor and acceptor drives dissociation of the exciton into free charge carriers. The mechanism is depicted in Fig. 1.

For efficient solar cells, the created charge carriers need to be transported to corresponding electrodes within their respective lifetimes. The charge carriers are finally extracted through ITO-coated glass matching the HOMO level of conjugated polymer (hole contact) used on illumination side and metal electrode matching the LUMO of fullerene PCBM (electron contact).

Organic PV is an emerging solar technology with improving cell efficiency (currently 13.2 per cent), boosting initial lifetime (more than 5000 hours) and potential for roll-to-roll manufacturing processes. It is well suited for building-integrated PV market because of the availability of absorbers in various colours and the ability to make efficient transparent devices.

It is heartening to find that several printing and coating technologies—such as gravure printing, flexo printing, screen printing, slot die coating and, most recently, ink-jet printing—are compatible with organic semiconductor processing. The printing solvent is evaporated when heated to moderate temperatures, producing a dried layer of the photoactive polymer. The modules are encapsulated between thin, flexible over-laminates, which protect active layers from mechanical abrasion and the environment. The advantages are low investment, printing and coating at a high speed, and no limitation on the substrate width. The processing steps are summarised in Fig. 2.

Thin, lightweight and flexible organic PVs are well suited for use on the outsides of buildings and on irregularly shaped products, such as fabrics for backpacks and tents. Several companies are actively pursuing these applications of organic PVs. Prominent among them are Solarte Belectric, Heliatek, Eight19, epishine, SolarWindow, Armor Beautiful Light, Raynergy Tek, Next Energy Technologies, Solarmer and Sunew Brasil. Dresden, Germany-based Heliatek, for example, has several pilot projects under way that highlight their ability to integrate foil-like organic photovoltaic modules into building facades made of glass, concrete and metal.

Heliatek has photovoltaic module production capacity of 10,000-20,000 sq. metres per year and their mass production target year is 2018. The other leading manufacturers of organic photovoltaics are Merck, Sumitomo, Mitsubishi and infinityPV.

InfinityPV sells solar cells and modules specifically for educational purpose, testing and manufacturing analysis. In 2013, it developed a large-scale roll-to-roll printing technique and record of connecting 16,000 organic solar cells in series. InfinityPV also makes solar chargers for phones. The device features a hand-sized case with a retractable organic photovoltaic panel and a built-in lithium-ion battery.

The key hurdle in the commercialisation of organic photovoltaics is financial, not technical. Organic PV cells’ low-cost advantage can be attained only when components and modules are produced at a much larger scale of at least one million sq.m per year, which requires a high investment, and pilot-scale demonstrations to boost investors’ confidence.

Dye-sensitised solar cells

Dye-sensitised solar cells can produce electricity in different light conditions, indoors and outdoors, enabling users to convert both artificial and natural light into energy to power a broad range of electronic devices.

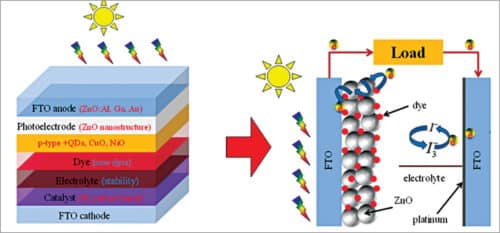

All photovoltaic devices generate electricity through a series of light absorption, electronic excitation and charge separation events. In dye-sensitised solar cells, these phenomena occur in separate molecular layers, as depicted in Fig. 5.

Dye-sensitised solar cells have a porous network of disordered titanium dioxide nanoparticles that are coated with light-harvesting dye molecules and are typically surrounded by a liquid-phase electrolyte. When light beam passes through the transparent electrode of a dye-sensitised solar cell, it is absorbed by a dye (red), generally a ruthenium complex which coats with ZnO or TiO2 nanoparticles (gray). The process creates photo-induced pairs of negatively charged electrons and positively charged holes (e–/h+). The charges separate at the surface of the nanoparticles: Electrons are injected into and transported through the ZnO or TiO2 layer to one electrode, and positive charges migrate via the electrolyte to the opposite side of the cell, generating electric current.

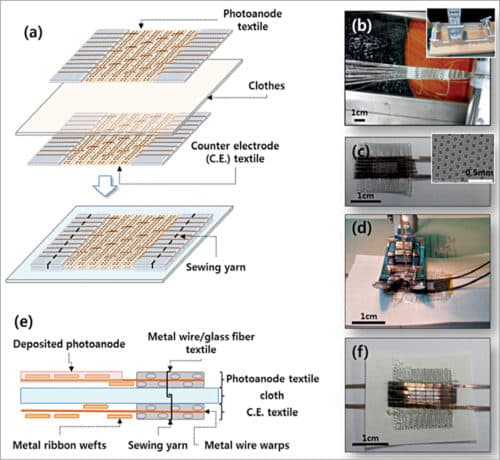

Dye-sensitised solar cells were invented in 1991 by Professor Michael Grätzel of the Swiss Federal Institute of Technology, Lausanne, and coworker Brian C. O’Regan. Their work sparked a wave of dye-sensitised solar-cell research and led to the founding of several start-up companies.Dye-sensitised solar cells have attracted much interest due to their low fabrication costs, relatively high efficiency (especially under weak illumination), and ability to incorporate the dye colour employed. The textile form of these solar cells has several advantages over other types of solar cells, including light weight, high flexibility and mechanical robustness. Recently, the market demand for wearable devices has pushed interest in the development of high-efficiency textile-based dye-sensitised solar cells for energy suppliers. The concept of textile-based DSSC is portrayed in Fig. 6.

Dye-sensitised solar cells also find application in building-integrated photovoltaics where solar panels can be built into various parts of a building’s shell, including the rooftop. Silicon cells are preferred for rooftops as these are best for direct sunlight. However, dye-sensitised solar panels work well in diffused light, where silicon technology fails. For that reason, thin sheets of translucent dye-sensitised solar cells can be sandwiched between panes of glass, turning ordinary windows, skylights and glass facades into electricity generators.

Several companies are commercialising dye-sensitised solar cell technology, with Dongjin Semichem of South Korea and G24 Power Newport of the UK being the pioneers. Dongjin Semichem has the capacity to produce tens of thousands of modules every year. The aesthetic features of dye-sensitised solar cells are attracting architects, construction materials companies and window manufacturers. Dye-sensitised solar cells also power small electronic devices. One application gaining importance is the Internet of Things (IoT), which refers to a network of appliances, vehicles and other objects that are fitted with sensors and other electronic components to enable them to collect and transmit data.

G24 Power sells under the trade name GCell. It offers a dye-sensitised solar cell-powered Bluetooth-enabled wireless keyboard and plans to start shipping dye-sensitised solar cell-powered beacons that broadcast Bluetooth signals.

One demerit of dye-sensitised solar cells’ early designs is that the liquid electrolyte, typically an organic solution of the iodide/triiodide (I–/I3–) redox couple, is corrosive, volatile and prone to leaking. It can react with the dye, which reduces its long-term stability.

In year 2012, researchers at Northwestern University successfully replaced the liquid electrolyte with a novel semiconducting inorganic solid called fluorine-doped cesium tin iodide (CsSnI2.95F0.05). It overcame the problem of corrosion and reactivity, and led to cells with conversion efficiencies of around 10 per cent.