The problem with current machine monitoring systems is their reliance on local servers, leading to higher maintenance costs and limited scalability. A serverless device entirely deployed in the cloud can offer real-time monitoring and maintenance actions, enabling more efficient machine maintenance, reducing downtime, and improving productivity with a device developed with various features which will be a much more suitable solution for the industry machine fault occurrence.

Brief into serverless applications

Serverless computing, also known as Function-as-a-Service (FaaS), is a relatively new model of cloud computing that allows developers to build and run applications without managing the underlying infrastructure. In a serverless system, the cloud provider takes care of the servers, virtual machines, and operating systems, leaving developers free to focus on writing code. Traditionally, when building an application, developers would have first to set up and configure a server, operating system, and other infrastructure components. This can be time-consuming and require specialized knowledge in areas like networking and security. With serverless computing, however, developers can skip these steps and start coding right away.

In a serverless system, developers write functions, which are short pieces of code that perform a specific task. These functions are then uploaded to the cloud provider’s platform, where they are stored and executed on demand. When a user interacts with the application, the appropriate function is triggered, and the cloud provider automatically provisions the necessary resources to run it. One of the key benefits of serverless computing is its scalability. Because the cloud provider automatically scales resources up and down as needed, developers don’t have to worry about capacity planning or over-provisioning. This can save time and money, as well as improve the performance of the application. Another advantage of serverless computing is its cost-effectiveness. With traditional computing models, developers are typically charged for the time their servers are running, regardless of whether or not they are being used. With serverless computing, however, developers are only charged for the actual time their functions are executing. This can lead to significant cost savings, especially for applications with irregular or unpredictable usage patterns.

Serverless computing also offers greater flexibility and agility than traditional computing models. Because developers don’t have to worry about managing infrastructure, they can focus on writing code and iterating quickly. This can lead to faster time-to-market and a more responsive development process. Despite its benefits, serverless computing does have some drawbacks. One potential issue is the “cold start” problem, which occurs when a function hasn’t been used in a while and needs to be re-provisioned by the cloud provider.

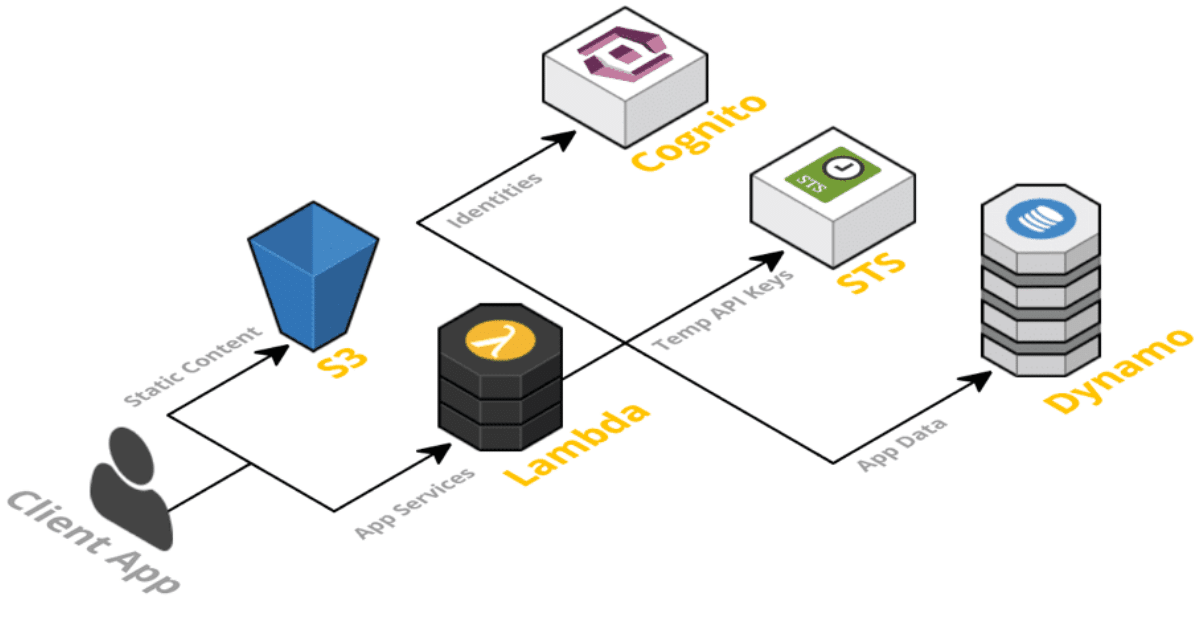

This can lead to a delay in response time, which may be unacceptable for some applications. Additionally, because developers don’t have direct control over the infrastructure, it can be more difficult to troubleshoot and debug issues. In conclusion, serverless computing represents a significant shift in the way, developers build and deploy applications. By abstracting away the underlying infrastructure, serverless computing allows developers to focus on writing code and building functionality. While it does have some limitations, the benefits of serverless computing – including scalability, cost-effectiveness, and flexibility – make it an attractive option for many use cases. As the technology continues to mature, it’s likely that we’ll see more and more applications built using serverless computing. figure 1, depicts the architecture of the serverless concept.

This sort of functioning of architecture where so many have been automated with the API. what is API then? API stands for “Application Programming Interface.” It is a set of protocols, routines, and tools for building software applications that specify how different software components should interact with each other. APIs provide a way for different software systems to communicate with each other in a standardized way, allowing developers to create new applications by leveraging existing functionality. APIs are widely used in modern software development, allowing developers to easily integrate different systems and services. For example, an e-commerce website might use APIs to integrate with payment gateways, shipping providers, and other services. APIs can also be used to expose data or functionality to third-party developers, allowing them to build new applications or services that extend the functionality of existing software systems. When this sort of technology, which is available in Industry 4.0, is used in real-time to eliminate problems that are not traditional but have a huge impact on the industry, The foremost asset that affects the profit and the manufacturing cycle or production, due to which the firm faces huge losses, machines. Machine faults are a common occurrence in industrial settings and can cause significant losses. These faults are generally characterized by a deviation from the normal operating conditions of the machine and can result from a variety of factors, such as wear and tear, misuse, and external factors like power surges and environmental factors.

Working functionality of the device

When a machine fault occurs, it can have several negative effects on an industry, including lost productivity, wasted materials, and increased maintenance costs. Lost productivity occurs when the machine is out of commission, leading to a decrease in the number of products that can be produced and shipped. This can lead to missed deadlines, unhappy customers, and ultimately a loss in revenue. Additionally, wasted materials occur when the machine is not functioning correctly, leading to reject products that do not meet the required quality standards. This not only results in additional costs to replace the wasted materials but also leads to lower profits due to decreased production rates. Increased maintenance costs can also be a significant effect of machine faults. When a machine is not operating as expected, it may require additional maintenance and repairs, leading to increased downtime and lost productivity. Moreover, if the machine requires replacement parts, these parts may be expensive and take some time to arrive, further exacerbating the situation. In conclusion, machine faults can have serious consequences for the industry, including lost productivity, wasted materials, and increased maintenance costs. It is therefore essential for companies to invest in preventative maintenance and regular machine checks to minimize the risk of machine faults and their negative effects. As a result, there is a high demand for fault detection and alert systems for machines, and even these sorts of devices are already in use by many industries, and even some big giants like Deloitte provide cloud-based data collection facilities as a service for the major industries and production houses that have machines in daily use. If you think properly, there is a problem, even though if you include a fault detection system with the machines, it is again a great problem because there will be 100s or even more machines, which are medium-scale machines too, or different types of machines that will have different parameters due to which they could face failure. Whereas to solve this problem and automate the entire system as a very efficient technology, the device acts as an intermediary that will be an interface between the cloud platform and the hardware, i.e., an electronic device that will monitor the parameters of the machine, which would make the device susceptible to failure. Thus, a device has the feature of sensing the temperature change in the machine, and the vibration will be monitored throughout the functioning of the machine. One of those detection devices integrated with this device is a vibration and surface mount temperature sensor.

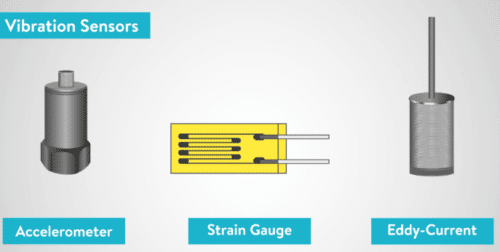

A vibration sensor is shown in figure 2, which works on the principle of detecting and measuring vibrations or oscillations of an object or system. The sensor detects these vibrations and converts them into electrical signals that can be analyzed to determine the frequency, amplitude, and other characteristics of the vibration. This information can be used to monitor the condition of machines, structures, and other systems, allowing for early detection of potential faults and maintenance needs.

A surface-mount temperature sensor shown in figure 3, works by using a thermocouple or resistance temperature detector (RTD) to measure the temperature of a surface. The sensor is mounted directly onto the surface using a conductive adhesive, and the temperature is measured through the conductive material. The sensor produces an electrical output that can be read and interpreted by a controller or computer system, allowing for accurate temperature monitoring and control in a variety of industrial and commercial applications.

Here, it is possible to change the parameters that are being monitored by changing the sensor connected to this device, and we could even increase the capability of the device so that it could even analyze and sense different parameters of an entirely different machine, which could detect the normality or abnormality of the machine. Thus, to make this compatible with Industry 4.0, this device is being built with a base of a WIFI-enabled microprocessor that is available in a microcontroller, which thus can establish a connection between the various networks and the internet wirelessly and even transmit and receive data. Vibration and temperature sensors are commonly used for machine fault detection in industrial settings. Vibration sensors detect and measure the vibrations of a machine, while temperature sensors measure the temperature of various machine components. Together, these sensors can help identify potential machine faults or abnormalities, such as excessive friction or wear, misalignment, or overheating. By monitoring these parameters over time, companies can identify trends and patterns that may indicate an impending failure or maintenance need.

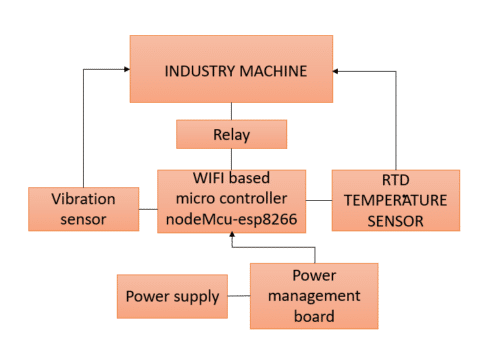

To monitor see figure 4, the parameters as discussed above the machine’s data will be extracted by the sensors and availed by the device, and the data will be continuously dumped in the cloud database. In this project, the work really solves various problems like the need of a physical device to store the data, which would again increase the performance of the device that is installed with the device, and even that device too will be altered and should be fixed and re-fixed again and again to replace the storage device or to take the data out for analysis where real-time analytics of the device is not possible for the machine and then this device also solves an major problem where these devices attached with the machines does not require a lot of cloud data base rather than that all the data will be stored and analyzed for every machine in different cloud channel where the data obtained from the machine in real-time is being analyzed and then being used to increase the efficiency of the machine using machine learning , where the data will be project in a CSV format those data will be available for any time view and will be used for analytics and the aggregation of the data are represented in two different plots in the google sheets where the sheets is connects to cloud data base and that data base will be having these data’s which is alterable and easily can be accessed by any derive which we have which could be connected ti internet and the cloud channel is being operated by the device developed where it will trig the data acquired from the machines, and these send commands to the interface where this commands will be controlling the different status widgets available in the projecting interface which can a web channel ,website or a cloud interface. And this device will send command to the web application where here the data will be sent as alert message to the respective indication will be imitated like voice over call will be sent and mail will be established from the device through if any anomalous functioning of machine is detected. And as an added feature, it has a relay that turns off the machine once a fault is detected in its functioning and it is kept at rest until the issue is rectified by the field engineers who were informed of this event.

Conclusion

This device is a simple and compact device that will be suitable for machines for fault detection, and upon changing the sensor integrated with the device, it would be used with various devices that are used in this mode of industry and are upgraded with Industry 4.0. Thus, as this uses a cloud platform in its functioning, it is a centrally managed server-less device where you can access all the machines with different channels, and the machine fault will be displayed in the widgets developed in the interface, along with the fault status and other data. Upon detection of a fault in a machine, the device triggers the API, and the respective machine in charge will get a voice-over call from the machine reporting failure and the mail will be sent to the different levels of management who are responsible for the rectification of this fault in the production area or area where all these data are done by that device even though it does not have a GSM or any other device in it, and once failure is detected the machine is turned off till the problem is rectified.

Duraiarasu E IIIrd year, B.E ECE, Rajalakshmi Engineering College, Chennai, Tamil Nadu.