We come across speakers in various shapes and sizes in our daily life. These are made to give the best performance possible within the size and price constraints. But what if we did not have any constraint, and wanted to produce the best possible speakers? Nature has solution to most problems, including this. Read on to find out, how.

It appears that Mother Nature has a general tendency to create objects in the shape of logarithmic spirals like arms of spiral galaxies, human cochlea, nautilus—a type of molluscs found in deep sea, spirula—a deep water squid, etc. The galaxies in space are differentially rotating, which causes a disturbance in the disc to wind up into a spiral form. The stars and gas in the disk of a galaxy exert considerable gravitational force that helps maintain the spiral form against the tendency to disperse. The tight wound spiral shape of cochlea—in contrast to the stretched-out version found in birds or reptiles—is useful for packing a slew of hearing parts into a very small space. Another benefit is that the distinctive snail shape enhances the ability of the ear to detect low-frequency sound.

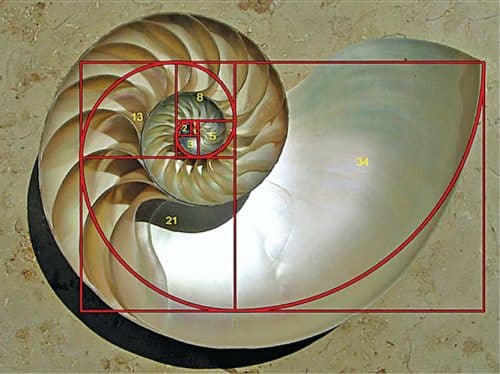

Fibonacci was one of the most famous mathematicians who in 1202 introduced the Fibonacci sequence 0, 1, 1, 2, 3, 5, 8, 13, 21, and so on. As you may have noticed, each number in Fibonacci sequence is the sum of previous two numbers. By drawing circular arcs connecting the opposite corners of squares, whose side lengths are successive Fibonacci numbers, that is, 1, 1, 2, 3, 5, 8, 13, 21, and 34, a logarithmic spiral can be created.

Nautilus mollusc

The nautilus is a marine mollusc found in Indo-Pacific at a depth of several hundred metres. The nautilus shell presents one of the finest natural examples of a logarithmic spiral as can be seen in Fig. 1.

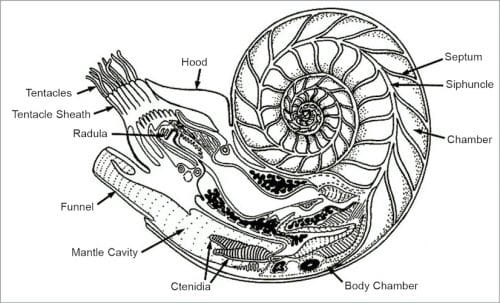

A section cut of a nautilus shell is shown in Fig. 2. Its logarithmic coiled tapered tube saves space, and when it grows, it need not change its shell. Inspired by the natural geometry of the shell of nautilus and understanding its function, audio engineers adopted logarithmic spiral shape to construct a sound system that not only looks great but also sounds better.

High-fidelity sound reproduction

Speakers require an enclosure to reproduce sound faithfully. The enclosure prevents the sound waves generated by the rear-facing diaphragm of an open speaker driver from interacting with the sound waves generated at front of the speaker driver. Because the forward and rearward generated sounds are out of phase with each other, any interaction between the two in the listening space creates a distortion of the original signal that was intended to be reproduced. Moreover, because the sound waves would travel different paths through the listening space, the sound waves of an unmounted speaker would reach the listener at slightly different times, introducing annoying echo and reverberation.

Hence loudspeakers are not used without enclosures. The geometry of an enclosure also plays a role in managing vibration induced by the driver frame and moving airmass within the enclosure.

Enclosures can have adverse effect, unless these are well-designed, like panel resonance, diffraction from cabinet edges, and standing wave energy from internal reflection. These problems can be alleviated by choosing proper geometry of the enclosure such as avoiding sharp corners on the front of the enclosure. Curved speaker enclosures, which taper exponentially and are in the shape of a logarithmic spiral like nautilus mollusc, can address most of these problems.

Sometimes, the differences in the phase response at frequencies shared by different drivers can be solved by adjusting the vertical location of smaller drivers, so that the wavefront of all the drivers is coherent at or around the crossover frequencies in the speaker’s normal sound field.

The box is typically made of wood, wood composite, sand mixed with resin, and more recently reinforced plastics. For damping the standing waves, fibreglass, felt made of jute, bonded acetate fibre, or wool can be used.

Ideally, a loudspeaker cone should respond equally to excitations throughout the frequency range so as not to favour one more than any other. However, the cone does have a set of natural frequencies, so when excited at these frequencies it will resonate, that is, respond more in that natural frequency than others. One way to address this problem is to make the speaker cone from a material that absorbs energy, like Kevlar, which is quite costly but helps in spreading the effect of resonance so that it is not so noticeable.

Another procedure is to divide the frequency range into, say, three or four parts and electronically allocate—preferably through active crossovers—each part of the frequency range to a separate cone through a separate amplifier. By following this route, each speaker cone can be designed to cater for a limited range, and its shape and material can be so chosen that its natural frequencies do not spoil the sound.

Active crossover functions in a different mode than a passive one. Whereas passive networks split an amplified signal coming from one power amplifier so that it can be sent to multiple drivers, an active crossover splits up audio signal prior to amplification, enabling it to be sent to two or more power amplifiers, each of which is connected to a separate driver type. There is less likelihood of clipping, consistent crossover behaviour, and there is less loading on each amplifier, if active crossover is used. We can thus fine tune the whole system. Nautilus shaped speakers are generally provided with active crossovers to enhance their sound quality.

Transmission line

Nautilus shaped speakers are a variant of transmission line (TL) loudspeakers. A TL speaker has an enclosure design that uses the geometry of an acoustic transmission line within the cabinet. An acoustic transmission line uses a long duct for guiding sound waves, with minimum loss of energy, by restricting the transmission of energy to one direction without physical constraint. In this design, sound comes from speaker’s back instead of reverberating as we see in simple box-type enclosure. It is directed into a long folded or logarithmic spiral damped pathway within the speaker enclosure, which allows far greater control over the reproduction of sound and use of speaker energy, thereby improving the quality of resulting sound.

The pathway may vary in size and taper and may be open ended or close ended in a nautilus shaped speaker. Closed designs have negligible acoustic output from the enclosure, except from the driver. Such a design ensures that undesired resonances, reflections, and energies, which would otherwise cause undesirable auditory effects, are selectively damped because of the duct.

As a rule, a TL speaker tends to have exceptionally hi-fi low frequency response, far below subwoofer, reaching into infrasonic range as low as 17Hz without the need of a separate subwoofer driver. It creates a more spacious soundstage. The speaker’s tapered cross-section avoids parallel internal surfaces that encourage standing waves. The enclosure behaves like an infinite baffle, potentially absorbing most of the speaker unit’s rear energies.

TL speakers employ tube-like resonant cavity, with the length set between 1/6 and 1/2 the wavelength of the fundamental resonant frequency of the loudspeaker driver being used (generally 1/4 for nautilus shape). The cross-section is typically tapered down at the terminus to about 1/4 of the starting area. To match the sonic purity of tweeter and mid-range speaker, the bass needs a waveguide pipe of about three metres length, which is impractical. But curled up horn shape with a height of 1.2 metres, like a nautilus, meets the demand. Thus, there is a great saving in space.

One key advantage of a TL speaker is its ability to conduct the back waves behind the driver more effectively away from it, reducing the chances for reflected energy permeating back through the diaphragm out of phase with the primary signal. The second benefit is that the resulting audio time is coherent, that is, in phase. A TL speaker can produce the full range of sound without using a subwoofer.

Makers of nautilus shaped speakers

Well-designed nautilus shaped speakers are legendary in their performance. These can be manufactured by moulding or by hot press, but most conveniently by 3D printing. 3D printing is a way of creating three-dimensional solid objects by building up the object layer by layer using a 3D printer and a computer.

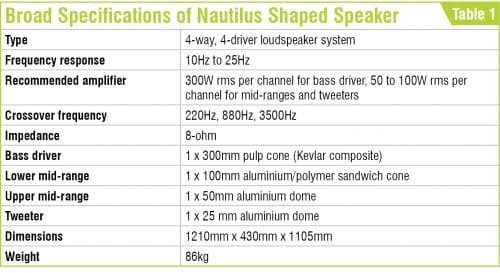

Nautilus speakers are made among others by Bowers & Wilkins, a British company, who are pioneers in making the iconic shaped speakers shown in Fig. 3. It is a 4-way speaker system, where the woofer is housed in the logarithmic spiral and three other mid-range speakers and tweeters are placed in individual tapered tube housings, independent of the nautilus shaped woofer enclosure, at the top. It is quite big with 1210mm height, 430mm width, 1105mm depth, and weighing about 87kg. It costs a fortune, about $70,000 a pair.

The cost is so high because of the expensive materials used, costly machines and tools required to make them, and every part is hand-crafted to achieve better sound quality and reliability, which is further augmented by marketing and branding expenses.

Another variant of two-way spiral speakers is shown in Fig. 4.

A small company called Deeptime in Prague, a Czech design studio, also makes the logarithmic spiral speakers. They call it ‘Spirula,’ inspired by the geometry of deep-sea squid named Spirula. It is made by 3D printing using sand mixed with hardener (Fig. 5). It has excellent damping property due to use of absorbent fibre. It is a bookshelf type speaker costing around $1000 with a frequency range of 75Hz to 20kHz. It uses only one 7.5cm (3-inch) full range driver.

Vivid Audio, UK also makes similar transmission line speakers with exotic curves, as shown in Fig. 6. It is a four-to-six driver, three-way, floor-standing speaker with its internal volume of 90, 45, or 25 litres. It embodies the same engineering philosophy as the nautilus. It costs about $26,000 for its top-line model. The cabinets are constructed out of a glass-reinforced Soric-cored sandwich composite. Soric is a honeycomb shell fabric that is designed for laminates. Three layers of the fabric are placed into an airtight mould, the air is pumped out and the bonding agent is pumped in. The result is a light and rigid panel.

Many audio enthusiasts make nautilus shaped speakers at home such as the one in Fig. 7.

It has been reported that it took 400 hours of work and 112 wooden discs, every one different in inside and outside diameter, which were turned on a lathe machine and joined together with epoxy. The skeleton was made of wood and steel circles and lined with polyester fibre to prevent expansion of wood with time. Its base was cast in concrete with lead pellet aggregate to prevent vibration. The sound quality was magnificent.

Features of nautilus speaker

A well-designed nautilus shaped speaker is a magnificent talking machine that adds nothing to, nor takes anything away from the input signal. Which means that it is totally free of resonances in the enclosures as well as the drivers. To achieve this goal, it is necessary to use a 4-way speaker system with active crossover network in an unusual logarithmic spiral shape. Broad specifications of this system are given in Table 1.

The whole frontal profile of the enclosures is smoothly rounded to avoid diffraction effects.

Bass unit enclosure. The bass unit fires into a tapering tube, but the tube is a logarithmic spiral coiled to save space. This type of loading results in an over-damped bass alignment. The roll-off is gradual but starts at a relatively high frequency, which requires an active crossover to provide the necessary equalisation.

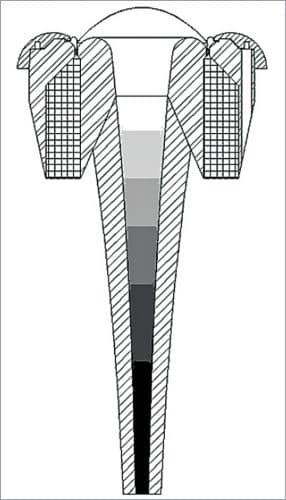

Enclosures for tweeter, lower and upper mid-range drivers. Upper mid-range driver and the tweeter have dome type diaphragm, which requires removal of any hint of cabinet coloration due to resonant air pockets. Providing an opening out hole in the pole to the greatest diameter possible allows the rear radiation to emerge unhindered and proves an effective way of smoothing out back radiation and prevent resonance. Coupling the driver to the end of an exponentially tapered long tube (about 680mm long for lower mid-range speaker), packed with fibrous filling, gives a very good result (see Fig. 8).

The shape of the lower mid-range speaker is like a small sphere attached to a long tapering tube. This combination is better than either a simple sphere or tube because it removes resonance.

All three drivers, that is, tweeter, upper mid-range, and lower mid-range speakers, employ straight exponentially tapering tubes to absorb radiation from the rear of the diaphragms. And all feature profiled holes through the centre of the magnet structure as the start of the tube. The exponential profile has been designed to ensure that the cut-off frequency of the tube is low enough to absorb all wayward energy in the operational bandwidth of the respective speakers and reduces resonance to the point of insignificance.

The tapered tubes are all filled up with absorbing wadding material. This allows the sound energy radiating from the rear of the dome to pass through the pole piece into the tube, without being reflected towards the dome. The wadding is packed loosely at the front and becomes denser and denser as it moves towards the rear end. The variation in packing density ensures that the acoustic impedance is also varied smoothly so that there is no reflection of energy.

The tapered tubes are made of aluminium and have good thermal bonding with the magnet back plate. These tubes then act as heat-sinks and significantly reduce the operating temperature by about 20 degrees centigrade. The tweeter diaphragm moves about 0.5mm only. Therefore, it is crucial to isolate it from mechanical energy arising elsewhere in the system. So, tweeter and its tapered tube are held in the housing by a rubber O-ring. The housing in turn is decoupled from the mid-range enclosures below by using isolator pads.

Upper mid-range and tweeter diaphragm is dome shaped, made from aluminium. High-frequency sound is very directional. Dome shape radiates sound with a wider dispersion pattern and so its signature is present over a wide listening area. Aluminium as a construction material is a good choice, because it is stiff and so it increases piston characteristics. It is also strong and light, so it produces a ‘bright’ sound. It has good damping property, so when music stops the driver also stops. As it is light, it moves quickly and easily. Being light and rigid, aluminium dome can capture subtleness of music, like delicate brush strokes across the surface of cymbals, with amazing accuracy. Its crowned voice coil bobbins and silver-plated pole piece can extend the bandwidth over an octave above the limits of human hearing.

The arrangement of housing of tweeter and mid-range speakers is shown in Fig. 9. The small frontal area of the mid-range speaker maintains a wide dispersion throughout the unit’s operating range, and the effects of the diffraction are reduced by chamfering the edges. The design of the tweeter enclosures is also based on the fact, that if it is barely wider than the radiating surface, the interference from waves diffracting off the outer edge is extremely low. The result is a smooth response and wide dispersion from the small radiating area.

Crossover

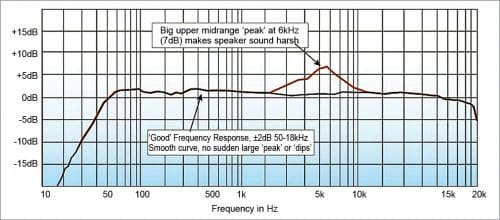

The active crossover frees the designer from the restrictions of limited drive unit sensitivity and response shape. So, it is a simple matter to provide any equalisation required and balance the system correctly. In addition, it allows the use of all-pass filters to alter the time delay of the drive units. Its active subtractive crossover network ensures flat crossover regions—amplitude and phase. The frequency response of a well-designed nautilus speaker system is shown in black line in Fig. 10. It should have no sudden large peak (shown in red) or sudden dips.

Driver units

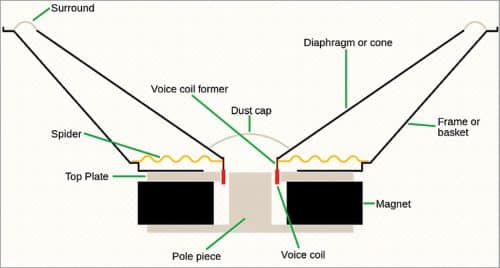

The requirement for a nautilus shaped speaker system to be resonance-free demands that all the units should work like perfect pistons within their pass bands and up to two octaves above them as well. Perfect piston drive units are those that move without bending and with a total freedom from resonances. This means that the voice coil moves like a piston of an internal combustion engine, and so should the diaphragm with zero flex, that is, it is infinitely stiff.

To have perfect piston motion, a minimum of four drive units are needed to maintain as nearly a constant directivity as possible—because perfect pistons become increasingly directional at high frequencies, and because at a high enough frequency the diaphragms cease to work like a piston, displaying high Q resonances. These drivers, within their linear motion limits, add nothing to the sound and take nothing away, which means they simply reproduce exactly what is given to them, and so perfectly converting electrical energy into sound energy.

Bass driver

The bass driver fires into a nautilus shaped coiled tube to save space. The unit’s diaphragm is a perfect piston within its operating range. But it cannot be extended much higher in frequency due to resonance problem.

A single large pulp-coned driver for the bass frequency is very suitable. It has been found that aluminium cones larger than 200mm (8-inch) sound distinctly metallic and hence are not preferred. Therefore, a bass driver cone is made from a low-density pulp using Kevlar and stiffening resin. Kevlar is a high-strength, heat-resistant synthetic material, which is five times stronger than steel and is generally used for making bullet-proof vests.

The cone is obtained through slow deposition rather than high compression, followed by a surface impregnation of hard thermosetting resin that has internal structure of an open network of long undeformed fibres. This means that the overall structure is effectively a thick laminate with a very high resistance to the static bending stress and localised flexure. The vast improvement to bass performance is due to pistonic motion and use of improved driver cone. The cone has variable thickness, which is instrumental in maintaining linear pistonic behaviour.

The dust cap has a significant influence on sound quality. With a hard oversized dust cap domes offer the best performance with pure bass. However, with increase in size its resonance degrades the sound quality. This problem is minimised by using a carbon-fibre dust cone dome attached conventionally to the bass driver cone but driven directly by the elongated carbon fibre former. Sectional arrangement of the woofer is shown in Fig. 11.

Voice coil

The voice coil is made from high-quality enamelled copper wire (sometimes also made from silver wire). Only 5% of power delivered to the voice coil is converted to sound energy. The rest 95% of power is wasted as heat, thereby increasing temperature of the voice coil. Coil’s resistance increases with temperature @ 0.4% per degree centigrade, which can significantly degrade its performance. So, special techniques are used for making the coils.

The best way to make a high-performance coil is to wind it on an alloy 1145 aluminium former by wet winding, while drawing the wire through a bath of high temperature adhesive comprising glass fibres impregnated with polyamide resin. This treatment makes the voice coil to survive up to a temperature of 300 degrees centigrade. Large magnet area, pole venting, large diameter of voice coil, and blackening of voice coil are some of the measures used to remove heat generated in the voice coil.

The performance of the speaker system can be further enhanced if magnetic fluid is used. In a conventional speaker, a voice coil is suspended on a damper made of cloth, called spider. As the voice coil moves up and down, the spider also vibrates. This generates secondary sound pressure waves that can cause distortion of sound. Solution to this problem is elimination of spider altogether and dipping the voice coil in micron-deep pool of ferrofluid.

Ferrofluid is a stable colloidal suspension of nano particles of magnetite in oil. The ferrofluid provides a free-flowing movement of the diaphragm to accurately reproduce the sound. The lack of dampening also means three decibels increase in volume and decrease of energy use by 35%.

Ferrofluid has approximately four times the heat transfer capacity of air, so it cools the voice coil very effectively. When applied to an eccentric voice coil, it distributes itself evenly around the air gap, forcibly centring the coil assembly, so there is no rub and scrape. A small amount of ferrofluid placed in the gap between the speaker magnet and voice coil is held in place by its attraction to the magnet and forms an excellent seal. It can increase short-time power handling up to 40 times and can be very useful for reproduction of classical music where short-time peak power requirement is often 100 times more than the average power.

Ferrofluid is not generally used in woofers, because their high excursion would tend to throw the fluid out of the voice coil gap. Ferrofluid can be very effectively used in tweeter as it has low wattage and can reduce clipping of sound to a great extent. As there is very little friction, it reduces energy consumption by 35% for reproducing the same loudness of sound as conventional speakers. It also improves the sound quality by nearly 3dB. This type of tweeter with ferrofluid, if used, would further enhance the performance of spiral speakers.

Rathindra Nath Biswas is a 1964-batch chemical engineering graduate from Jadavpur University, Kolkata. He was awarded a certificate for designing Benzol Plant by Giprokoks, USSR, and Certificate of Honour by Indian Institute of Metals. He has published 35 research papers in various journals. He retired from service as head – MECON, Durgapur.