A new 3D-printed polymer enables robots to perspire, leading to rapid cooling of several overheated motors and engines involved in the functioning of a robot.

The human body consists of numerous sweat glands for regulating body temperature while doing an intensive physical task and hence provide an adequate cooling effect. Having this functionality is critical without which internal body temperature can’t be monitored and controlled, which could result in severe failure of vital organs such as heart and brain.

Influenced by this phenomenon, researchers from Cornell University have created a soft robot muscle that can regulate its internal temperature through sweating and enable high-powered robots to operate for long periods of time without overheating.

“The ability to perspire is one of the most remarkable features of humans,” said T.J. Wallin, a research scientist at Facebook Reality Labs. “Sweating takes advantage of evaporated water loss to rapidly dissipate heat and can cool below the ambient environmental temperature. So as is often the case, biology provided an excellent guide for us as engineers.”

A feasible alternative

Typically, a powerful fan is employed to prevent overheating of motors and engines. However, these electro-mechanical machines take up space inside the robot and add weight. Furthermore, they also consume a lot of power as the cooling requirement increases.

So, to provide an alternative solution, the research team began by creating a nano-polymer material for sweating via a 3D-printing technique called multi-material stereolithography.

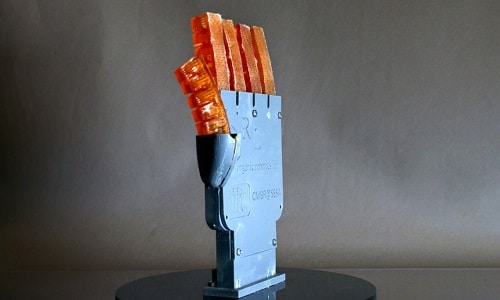

Using this material, finger-like actuators composed of hydrogels were created. These hydrogels had the capability to retain water and respond to temperature changes.

The base layer, made of poly-N-isopropyl acrylamide, reacted to temperatures above 30 degrees Celsius by shrinking, as a result of which, water squeezed out into the top layer of the polyacrylamide that was perforated with micron-sized pores. These pores have been designed to be sensitive to temperatures beyond 30 degrees Celsius, automatically release water (or sweat), and then close as soon sufficient cooling is achieved (of up to 21 degrees Celsius).

“The best part of this synthetic strategy is that the thermal regulatory performance is based in the material itself,” said Wallin. “We did not need to have sensors or other components to control the sweating rate. When the local temperature rose above the transition, the pores would simply open and close on their own.”

It was observed that this method was nearly six times faster in cooling off a robot’s internal mechanism, as compared to cooling when exposed to a fan.

Effective cooling

After several trials, the team incorporated the actuator fingers into a robot’s hand for grabbing and lifting objects. And as a consequence, it was discovered that the sweating not only cooled the hand, but lowered the temperature of the entire robot as well.

Future incorporations

Despite the disadvantage of hindering a robot’s mobility, the technology promises many new features, which the team plans to further improve.

The hydrogel texture responsible for lubrication could make a robot hand slippery, affecting its grip. This could be corrected by introducing tiny serrations, much like wrinkles on human skin.

Sweating would also require robots to replenish their water supply, which in turn could lead to a provision for drinking water like mammals (besides perspiring like them).

The ability for a robot to sweat could also lead to methods for absorbing nutrients, catalysing reactions and removing contaminants, which can coat the robot’s surface with a protective layer.

“I think that the future of making these more biologically analogous materials and robots is going to rely on the material composition,” said Rob Shepherd, associate professor of mechanical and aerospace engineering, Cornell University. “This brings up multidisciplinary research in this area, where really no one group has all the answers.”

It seems the time is not far away when this will be truly realised and give a new definition to the term ‘humanoids’.

Read the detailed research paper here.