Due to coronavirus we are now used to alcohol based sanitisation liquids and sprays but what about disinfecting items like goggles, keys, mobile phone, watch, currency notes, laptop, courier packets, etc that we handle? A convenient solution for disinfecting such items is an ultraviolet (UV) sterilisation box that you can build yourself.

Due to coronavirus we are now used to alcohol based sanitisation liquids and sprays but what about disinfecting items like goggles, keys, mobile phone, watch, currency notes, laptop, courier packets, etc that we handle? A convenient solution for disinfecting such items is an ultraviolet (UV) sterilisation box that you can build yourself.

Ultraviolet is electromagnetic radiation with wavelength of 10 to 400nm. It has shorter wavelength than visible light but longer than x-rays. The wide range of UV radiation is grouped into three main categories:

- UV-A with wavelength of 315 to 400nm

- UV-B with wavelength of 280 to 315nm

- UV-C with wavelength of 100 to 280nm

Across the world, UV-C sterilisation is an established method for inactivating pathogens, viruses, and bacteria. UV-C disrupts the DNA of pathogens and impairs their ability to perform vital cellular functions. The effectiveness of this germicidal exposure depends on the duration of exposure and the intensity and wavelength of the UV radiation. It is therefore necessary that sufficient UV-C light reaches all parts of the object being disinfected.

Features of this steriliser are:

- UV-C lamps operating at 254nm wavelength for effective germicidal effect

- Enclosed UV leak-proof box

- Reflective sides for maximising reflections and giving effective 360-degree coverage

- Magnetic hold of door/lid to keep it securely closed

- Rotary switch for setting exposure time from 1 to 10 minutes

- Timer can be paused, if desired

- Simple operation using Start/Resume and Stop/Pause buttons

- Display showing remaining time and alert messages

- Safety feature that shuts off the UV lamp if the door/lid of the box is opened

Construction

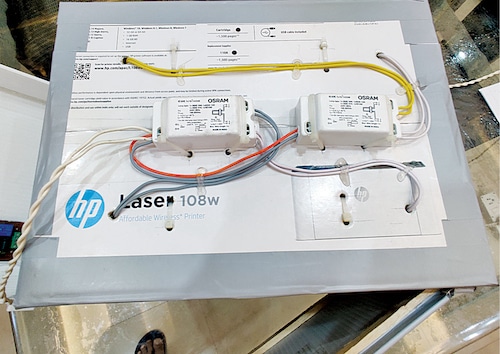

The UV steriliser can be made using a suitable-size stiff cardboard or wooden box, or any other sturdy box. (Direct exposure to UV-C rays is harmful to humans, so build a proper enclosure.) The author’s prototype was built using an empty printer box as shown in Fig. 1.

The top of the box was sealed and fixed while a slot was cut on the front side of the box as shown in Fig. 2. A 3cm edge (frame) was left on all sides of the opening so that the door could rest (close) along these edges. The door can be built using a cardboard sheet that is at least 2cm bigger than the opening to block the UV light properly.

A hinge can be made on one edge by cutting a 3cm strip from the door and sticking it again with a sturdy tape or a cloth strip. On the opposite edge three neodymium magnets can be embedded inside the cardboard to serve as a secure lock for the door. A thin iron strip (such as a piece of an old hacksaw) may be attached to the side edge of the box to which the magnets can stick.

Stick kitchen aluminium foil or silver craft paper on all inner sides of the box so that the UV light scatters all over inside the box. The outer side of the box can also be covered with craft paper. Install the two 11W UV tubes on ceiling of the box using ties. Draw the end wires connected to the tubes outside the top of the box where the two chokes are installed as shown in Fig. 3.

Circuit and working

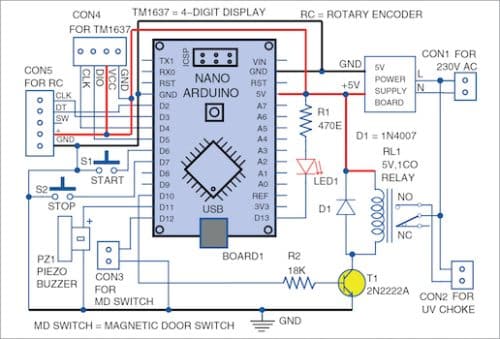

The controller is built around an Arduino. Arduino Pro can be used, which has a small footprint, though any Arduino variant would work. Circuit diagram of the UV sterilisation box is shown in Fig. 4. It comprises a TM1637 module, 5V DC power supply module (Module1), Arduino Nano (Board1), 5V single-changeover relay (RL1), a rotary switch, a magnetic door switch, two 230V AC operated UV tubes, two chokes, and a few other components.

The software sketch can be downloaded from EFY website and uploaded to the Arduino using the Arduino IDE.

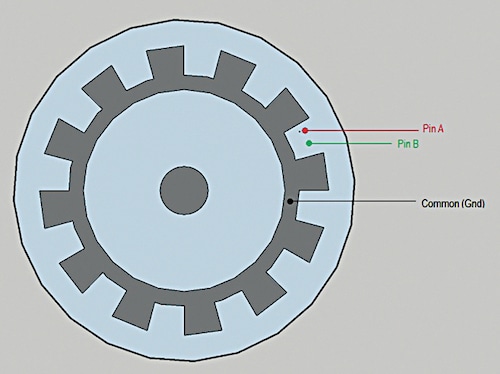

A rotary encoder is used for setting time-period. Though it looks like an analogue potentiometer, it is a digital device that can be fully rotated without any end stops. It does not give any absolute value but can be interpreted to give the direction of motion, and the pulses generated can be counted to give the new value. The most common rotary encoder is the scroll wheel on a computer mouse. Just like a mouse, the rotary encoder can be rotated and clicked (pressed). In this circuit, the inbuilt press switch is not used. Inside the encoder there is a slotted disk connected to the common ground pin C, and two contact pins A and B as shown in Fig. 5.

do you have the circuit diagram for this project? if have pls tell me i need it for my Final year project references

Hi Ammar, the circuit diagram is present within the article.

other question, where do u find the chokes needed for this UV box I couldn’t find it online and also is there a video of the UV box being build pls if u have

The author Ashok Baijal replies:

I purchased the items online from Amazon but should be available in the electrical markets. They are commonly used in water filters. I used the Osram brand.

2. I did not make a video while constructing the device but photos are given in the article. It is a simple build. The chokes and tubes are held to the carton box using zip ties.

3. I have been using my device for sanitizing the mask and keys, phone after every use without a problem even today.

Total cost of the project?

Dear Anwesha,

Calculate the cost at yourself as it varies from place to place.

Regards