Conformal coating inspection is now more challenging as the electronic advancement in the high-tech industries significantly increased the complexity of Printed Circuit Board design with more joints, higher component densities, and new package technologies on the Printed Circuit Board assemblies (PCBAs).

A conformal coating is a thin polymeric film applied to the surface of a printed circuit board (PCB) to protect the board and its components from the environment and corrosion. Conformal coating is essential for the board manufacturing process because it ensures electronic devices’ reliability and longevity by protecting them from environmental factors such as moisture, dust, and corrosive substances. The protection provided by conformal coatings allows for higher voltage gradients and closer track spacing, in turn enabling designers to meet the demands of miniaturization and reliability.

Additionally, the conformal coating will also aid the manufacturer in ensuring compliance with the IPC standards, specifically for those required to adhere to the standards of IPC Classes 2 (PCBAs with good quality and durability) and 3 (industries with the most stringent product requirements, such as aerospace and medical). Due to the demanding nature of the industry, electronics failures are intolerable as the products are required to cater to high, continuous and critical performance under harsh environments.

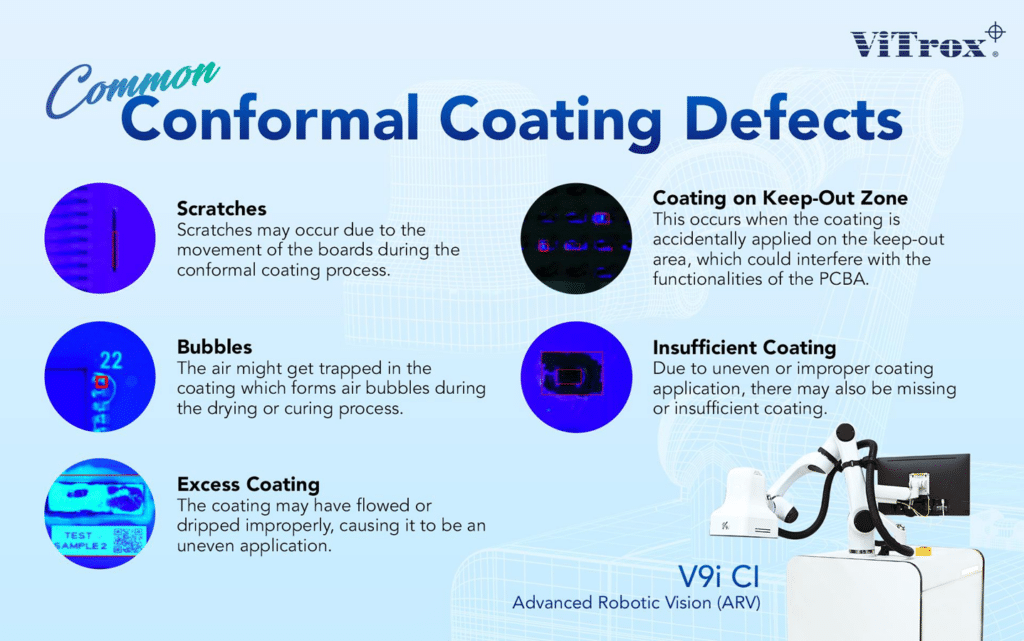

A newly manufactured board will generally function well. However, its performance can quickly deteriorate due to corrosion, mould growth, leakage, thermal shock and electrical failures. Therefore, it is important to have the coating applied correctly and evenly on the PCB in compliance with the IPC Standard (IPC-A-610). Defects on the PCB that are commonly found during the conformal coating process include bubbles, missing/insufficient coating, coating on Keep-Out Zone, foreign objects on coating, and many more.

Challenges Posed by Manual Inspection & Conventional CC AOI Inspection

In the current market, conformal coating inspection is often conducted by either manual labour or using conventional CC AOI. These two methods pose challenges to the quality and overall productivity of inspection.

Manual inspection or conventional CC AOI inspection is not ideal for users as it is less effective and has lower accuracy and lower speed. Human misjudgement may happen and it leads to quality issues. Besides that, manual inspection lacks traceability which causes users to not have proper references for comprehensive inspection analysis and preventive action. For the conventional Conformal Coating AOI, it does not have the flexibility to adjust the camera angle which leads to a limited inspection angle.

V9i Advanced Robotic Vision (ARV) Solution: Meeting Your Conformal Coating Inspection Needs

As compassionate innovators, ViTrox understands the significance of having a highly-accurate and reliable inspection system. It aids manufacturers in detecting any defects or non-conformities in the coating and minimises escapee during the manufacturing process. Hence, we innovated the award-winning V9i ARV Solution – and here are some of our key features which will be a game-changer to increase inspection accuracy, consistency and speed:

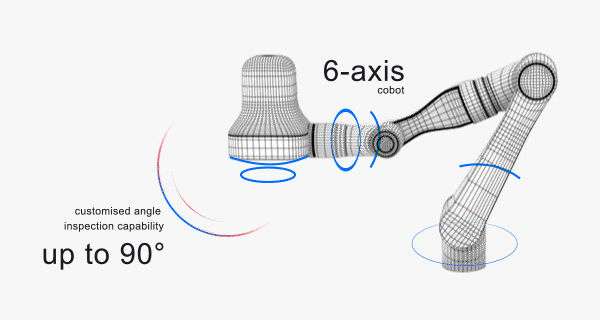

- 6-Axis Collaborative Robot (COBOT)

The V9i ARV solution is a 6-axis COBOT-based automated conformal coating inspection system that allows flexible inspection capabilities. The camera angle can be adjusted up to 90°, enabling conformal coating full coverage examination. Through the use of automation, the inspection process is made more impactful and effective, guaranteeing accuracy and consistency. The objective is to allow users to perform coating inspection with high flexibility as a human hand but with better consistency.

- Configurable Vision Module Design

Most of the conformal coating consists of ultraviolet (UV) fluorescence for the user to perform the inspection. V9i ARV system includes an ultraviolet-white (UVW) module specialising in conformal coating inspection. The UV lighting is harmless to the human eye with a 365nm wavelength which allows the user to operate it safely. Another important feature of the V9i ARV system is conformal coating thickness measurement. V9i ARV system offers coating thickness measurement capabilities for a coating range within 25μm ~ 500μm, with accuracy and repeatability lower than 5μm. Our V9i ARV solution is built with multi-focal vision, allowing inspection ranging from 5mm to 200mm, thus resulting in high-resolution images as clear as 14um/px for small defect inspection. The V9i ARV solution ensures complete inspection coverage and always delivers reliable and consistent results.

- Compact, Portable and Ergonomic Machine Design

Unlike conventional CC AOIs, our V9i ARV solution is compact and portable and can easily be docked next to conveyors without increasing the length of the production line, resulting in a more flexible and efficient inspection process. Users can connect the V9i ARV solution to their production for inline production mode by using the SMEMA connection for upstream and downstream communication. Otherwise, users can place the system for offline mode discussion with the existing conveyor.

An Example of the V9i ARV setup

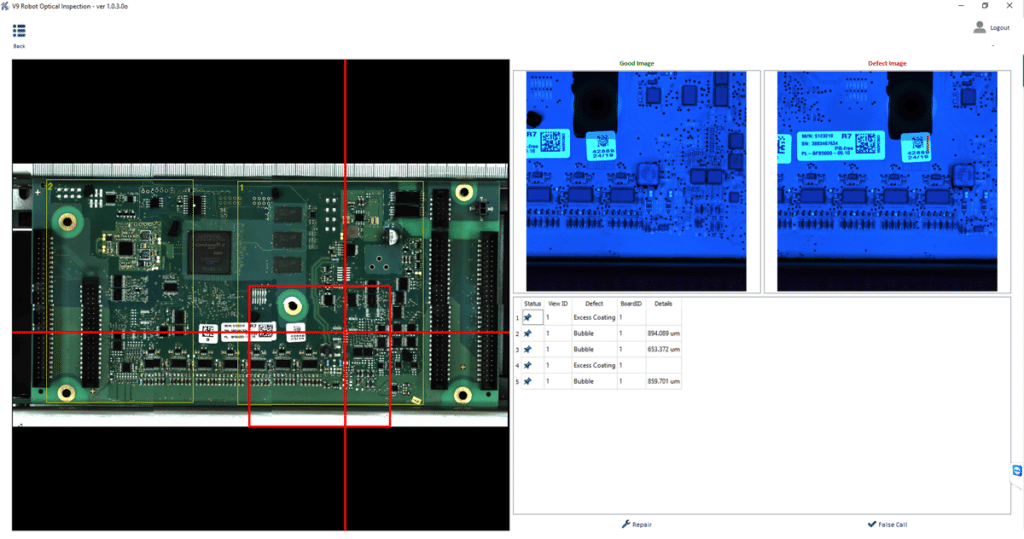

- User-friendly Setup for Zero-Experience Personnel

V9i ARV is user-friendly, and people without programming skills can easily adopt it within a short period of time. Developing a program from scratch would take roughly 2-3 hours, depending on the user’s experience with the system. The system can save up plenty of time in developing a program through Advanced CADless programming by learning the golden board samples. Hence, users only need to focus on fine-tuning or additional measurements required.

The intuitive graphic user interface (GUI) also creates a fresh user experience that makes it simple to write programmes with minimal effort. This GUI enables users to control the vision movement for viewing, utilising just one click to kickstart inspections and learning processes, as well as to view the inspection results updates simultaneously on the same interface. It is also simple to inspect all boards using a single board setting.

The combination of hardware and software has brought remarkable inspection results and quality assurance to our customers. After the inspections, all data will flow to the automated repair station (VVTS) for the operator to buy off at a remote station or the system area. For all customers, especially automotive customers, inspection data is crucial and every board inspected in V9i ARV will be recorded and stored in a database ViTrox Database Statistical Process Control (VDSPC) 2.0 for future review. Users can easily trace back the inspection data based on barcode scanning. In conjunction with the era of Smart Manufacturing, V9i Gen 2.0 is ready to connect with Industry 4.0 Manufacturing Intelligence – V-ONE through ViTrox and SMEMA connectivity.

- Extensive Inspection Capabilities

In addition to being a system for inspecting conformal coatings, ViTrox’s V9i ARV solution also serves as a final inspection solution. On top of conformal coating inspections, users can also use the V9i ARV solution to perform final assembly inspections! It is a cost-effective investment because the users can accomplish two inspection processes with one solution. The V9i ARV solution can also be configured to enhance inspection coverage and efficiency, providing even more value to your inspection process.

One of the configuration options is the V95i ARV Solution Rotator, which supports multi-angled PCBA and Box Build inspections within a solution, while the V97i ARV Solution Flipping Conveyor helps V9i ARV to perform top and bottom inspections. This configuration allows users to perform quick inspections without setting another flipper in the line, so stay tuned for more exciting updates on this configuration!

Key Takeaway

To summarise it all, conformal coating inspection is a crucial step to ensure compliance with industry standards and to prolong the lifespan and usability of your PCBAs. V9i ARV can help users address the potential issues arising from manual conformal coating inspections. Most importantly, it is an Industry 4.0-ready solution with real-time monitoring, analysis and preventive actions that guarantee inspection accuracy, consistency, traceability and reliability!