As the market demand for high throughput continues to grow, our R&D team continues to develop and enhance vision technologies to better meet customer needs. Hence, we are pleased to announce the newest edition – the V810i Series 3 (S3) Advanced 3D X-Ray Inspection (AXI) Solution.

Integrated with the latest ViTrox vision technological innovation and artificial intelligence (A.I.) capabilities, V810i S3 AXI enables users to optimise production throughput and enjoy speedy and accurate SMT inspection capabilities.

The New V810i S3 AXI

V810i S3 AXI has a new ergonomic outlook that saves space capacity for users. One of the space-saving designs is embedded with its RRS Server (3DCT) and Supermicro (System Server) in the machine, eliminating the location of the external servers at the exterior of the system.

The new V810i S3 AXI features our in-house developed Algebraic Reconstruction Technique (ART) with a model of sharp geometric 3D computed tomography (CT) that simplifies the process for users to perform accurate defect analysis results. In particular, V810i S3 AXI has equipped with machine Internet of Things (IoT) solutions which allow engineers to troubleshoot the systems easily and perform preventive maintenance actions to minimise production downtime.

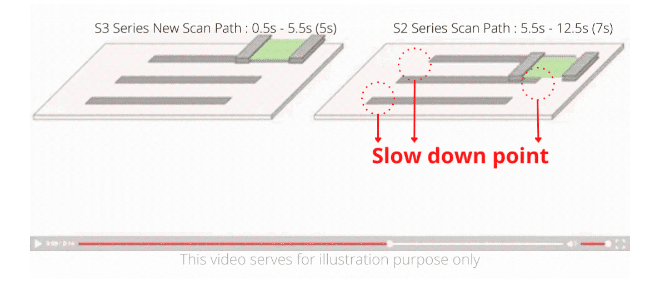

V810i S3 AXI is also equipped with a new Phase Shift Profilometry (PSP) to support the new Optical Assist System feature (OAS) which is capable of supporting barcode reading, optical alignment and bad mark detection. Additionally, the system enhances the inspection speed up to 30% faster with the new scanning route coupled with a new mechanical part on the stage. On top of that, it provides automated inspection with 100% test coverage.

With the new A.I. features to automate the inspection assignments, V810i S3 AXI is user-friendly with only requiring the users to verify the results. The existing A.I. programming, also known as intelligent tuning, is available for gullwing and leadless joint types. The same applies to the buyoff station where the A.I. assists the users’ buyoff of the Resistor, Capacitor and Ball Grid Array (BGA) defect result by displaying the confidence level of buyoff.

V810i S3 AXI also offers a new feature called Swift Fine tuning, where the system does not need to rerun any data but only adjusts the threshold. We believe that the Swift Fine tuning feature can save users more than 20% programming time for medium and complex boards!