A step-down transformer is an electrical device that reduces the voltage of an alternating current (AC) power supply. It consists of a primary winding, a secondary winding, and an iron core.

When an AC voltage is applied to the primary winding, it creates a fluctuating magnetic field in the iron core. This magnetic field then induces a voltage in the secondary winding but at a lower voltage level than the primary winding.

A transformer works on the mutual induction principle, also known as Faraday’s Law of Electromagnetic Induction, which states that the magnitude of voltage is directly proportional to the rate of change of magnetic flux.

To get a deeper view of the performance of a transformer, let’s understand its basics.

Mutual Induction

It means that a current gets induced in a coil when it comes in proximity to a current-carrying coil having varied magnetic flux. This induced current is directly proportional to the rate of change in current. Learn more about mutual induction.

Faraday’s Law

According to Faraday’s Law, any change in the magnetic field near the coil or conductor leads to the production of an electromotive force (EMF) that is induced inside the coil due to a change in magnetic flux.

Transformer Construction

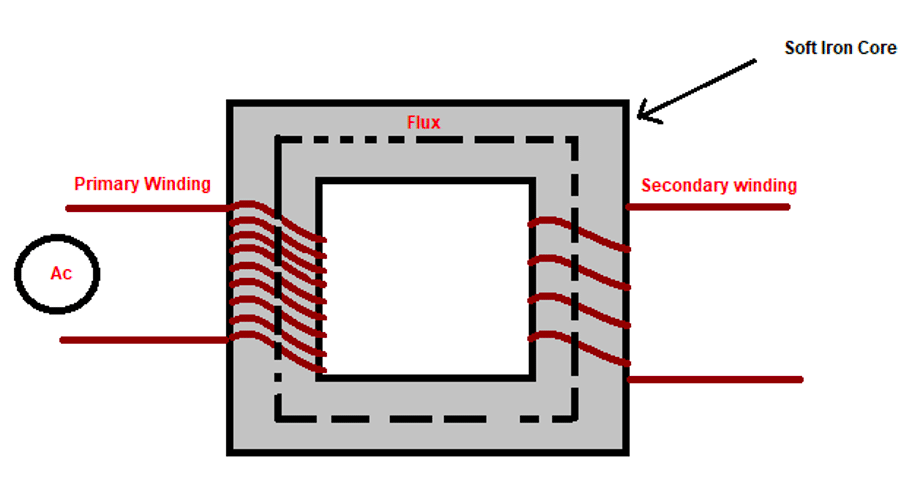

A transformer consists of the following main parts:

Core

The coils that are winded up on a certain material collectively form a transformer core. These cores are made of very high permeable material that is able to carry the flux.

The core of a transformer acts as a path or channel for the easy flow of magnetic flux.

These cores are constructed using ferromagnetic materials that have high permeability such as iron.

In transformers, we use thin metallic iron sheets instead of a single solid core because the single solid core causes a greater generation of eddy currents (Small currents that flow in a conductor due to changing magnetic field, causing energy loss) and this decreases the efficiency of a transformer.

Winding

The voltage transformers are winded with wires called coils. Here, we use wires with less resistance and good conductivity, which is required to get good efficiency from the transformer.

Generally, copper is used in transformer winding as it has good electrical conductivity and very low resistance compared to others. It is also not expensive like gold, silver, and platinum.

Transformer Working

A transformer works on the principle of mutual induction. So, when there is a change in the current of one coil, an electric current is also induced in the other coil in its proximity.

Every transformer consists of two coils or winding: primary and secondary. The primary winding is connected to the AC power source and the secondary to the load.

When AC (alternative current) is provided to the primary winding of the coil, a magnetic flux is generated. Through the transformer core, the magnetic field completes its path.

As the secondary winding comes in contact with this magnetic flux, an EMF is induced on it.

The strength of the generated EMF depends on the number of turns in the winding of the secondary coil.

N1>N2

where, N1 = Number of turns in the 1st coil

N2 = Number of turns in the 2nd coil

The relation between voltage and the number of turns in a coil is:

Vp/Vs = Np/Ns

where Vp = Voltage in the primary coil

Vs = Voltage in the secondary coil

Np = Number of turns in the primary coil

Ns = Number of turns in the secondary coil

What is a Step-Down Transformer?

The transformer that has a larger number of turns in the primary winding and a smaller number in the secondary winding is called a step-down transformer.

So as we can see from the previous equation for the relation between the number of turns in winding and voltage if the number of turns in the primary is greater than the number of turns in the secondary, then the EMF generated in the secondary is less than the primary input.

Hence, we get a lower voltage in the secondary coil of a step-down voltage transformer.

As the name indicates, the step-down transformer is used for converting higher voltage power into lower voltage power.

Step Down Transformer Formula

Now let’s understand the above process with an example.

Suppose we have an AC source that can produce 210 V.

If we use a transformer having Np (number of turns in the primary coil) = 20000,

And Ns (number of turns in secondary) = 100,

Then Vs (voltage at the secondary coil) is given by,

Vs = (Vp * Ns)/Np

Put the above values in this equation to calculate the voltage at the secondary coil.

I have left this work for you. Mention the right value in the comments.

Step-Down Transformer Types

| Step-Down Transformer | Definition | Application | Advantage | Disadvantage |

| Single Phase | A transformer that steps down voltage using single-phase AC. | Household appliances and small commercial systems. | Simple & cost-effective for low-power applications. | Not suitable for large-scale. |

| Center Phase | The secondary winding has a center tap (A connection point on the winding that allows for adjusting input or output voltage),

providing two equal voltages. |

Audio equipment, power amplifiers, rectifiers, etc. | Provides dual voltages (positive & negative). | Only for specific dual voltage needs, and complex wiring requirements. |

| Multi-tapped | Multiple taps on the secondary winding for different voltage levels. | Adjustable power supplies, voltage regulation, etc. | Flexible with multiple output voltages. | Complex design requires precise control. |

Applications of Step-Down Transformer

Step-down transformers are used in power adaptors and rectifiers to efficiently decrease the voltage. They are also used in electronic SMPS.

Other applications include:

- Power transmission lines

- Welding machines

- Voltage stabilizers and inverters

Advantages of Step-Down Transformers

- Step-down transformers are very efficient and can give the desired output with an efficiency of up to 99 percent.

- We can get the desired output voltage easily without loss of much power.

- They are less expensive and more reliable.

- They can be used to provide high currents and low voltages.

Step-Down vs Step-Up Transformer

| Parameters | Step-Down Transformer | Step-Up Transformer |

| Primary Function | Reduces voltage from high to low | Increases voltage from low to high |

| Winding | Contains more turns of primary winding than the secondary winding. | Contains fewer turns of primary winding than the secondary winding. |

| Voltage Transformation | Output voltage < Input voltage | Output voltage > input voltage |

| Current Transformation | Output current > Input current | Output current < Input current |

| Winding Turns Ratio | Primary to Secondary turns ratio, K > 1 | K > 1 |

| Applications | Used mainly in household applications, distribution grids, inverters, stabilizers, etc. | Used mainly in power plants for long-distance power transmission to increase voltage, X-rays, plasma cutters, etc. |

Some Common Questions about Step-Down Transformers

Q1. Can step-down transformers be used to increase the voltage?

No, step-down transformers are designed to reduce the voltage of an AC power supply. To increase the voltage of an AC power supply, you would need to use a step-up transformer.

Q2. How do you calculate the voltage output of a step-down transformer?

The voltage output of a step-down transformer can be calculated using the following formula: V_output = V_input * (N_secondary / N_primary)

Where V_output is the output voltage, V_input is the input voltage, N_secondary is the number of turns in the secondary winding, and N_primary is the number of turns in the primary winding.

Q3. How do you select the appropriate size of the step-down transformer?

The appropriate size of a step-down transformer for a particular application depends on the voltage and current requirements of the load (i.e. the device or devices that the transformer will be powering).

You will need to know the voltage and current ratings of the load and select a transformer with a primary voltage rating that is higher than the supply voltage and a secondary voltage rating that is equal to or higher than the load voltage.

The current rating of the transformer should be equal to or greater than the load current. It is important to select a transformer that is appropriately sized to avoid overloading or damaging the transformer or the load.

Q4. How do you connect a step-down transformer?

Step-down transformers are typically wired in a Delta or Wye configuration. In a Delta configuration, the primary and secondary windings are connected in a triangular pattern. In a Wye configuration, the primary and secondary windings are connected in a Y-shaped pattern. The specific wiring method will depend on the transformer and the application. It is important to follow the manufacturer’s instructions when wiring a step-down transformer.

Q5. How do you test a step-down transformer?

There are several ways to test a step-down transformer:

- Open circuit test: This test measures the voltage of the primary winding with the secondary winding open.

- Short circuit test: This test measures the current of the primary winding with the secondary winding shorted.

- Load test: This test measures the voltage and current of the primary and secondary windings with a load connected to the secondary winding.

- Temperature rise test: This test measures the temperature increase of the transformer under load conditions to ensure that it is operating within safe limits.

Q6. What are some factors that can affect the performance of a step-down transformer?

Some factors that can affect the performance of a step-down transformer include:

- The quality of the materials used in the transformer

- The design of the transformer

- The load placed on the transformer

- The frequency and voltage of the AC power supply

- The ambient temperature and humidity

- The presence of external electromagnetic interference (EMI)

Q7. What are some common problems with step-down transformers and how can they be resolved?

Some common problems with step-down transformers include:

- Overheating: This can be caused by overloading the transformer, using it at higher-than-rated frequencies, or operating it in high ambient temperatures. To resolve this issue, reduce the load on the transformer, use it at the rated frequency, and ensure proper ventilation.

- Humming or buzzing: This can be caused by magnetic fields interacting with other nearby electrical devices or by mechanical issues with the transformer. To resolve this issue, move the transformer away from other electrical devices or have a professional inspect and repair the transformer.

- Poor voltage regulation: This can be caused by an incorrect transformer size or load, or by a faulty transformer. To resolve this issue, ensure that the transformer is correctly sized and rated for the load and have a professional inspect and repair the transformer if necessary.