Low-power sensor nodes now have the ability to be easily integrated into the fabric and through motion detection, allow us to perform a range of activities, thanks to this latest innovation

Recent advancements in material electronics have allowed new ways to incorporate electronic circuits in wearables. Flexible electronics, for example, is an upcoming technology that is being gradually implemented into plastic substrates for providing ease of stretchability and flexibility. When it comes to textiles, the challenge of garment lifespan, fabric maintenance and ruggedness, end-user customisation, etc. hinder the efficient implementation of electronics. Many garments continue to employ rigid electronics by prioritising functionality over flexibility and comfortability.

In order to overcome this challenge, the project undertaken by researchers at the MIT Media Lab and Google presents a new technique for quickly integrating electronic sensors into snap fasteners (or buttons) of clothes. Called the SensorSnaps, these miniature electronic circuits securely attach to and detach from commercial snap fasteners. This provides minimal hindrance and improves flexibility in the movement of fabric.

Advanced electronics in a tiny space

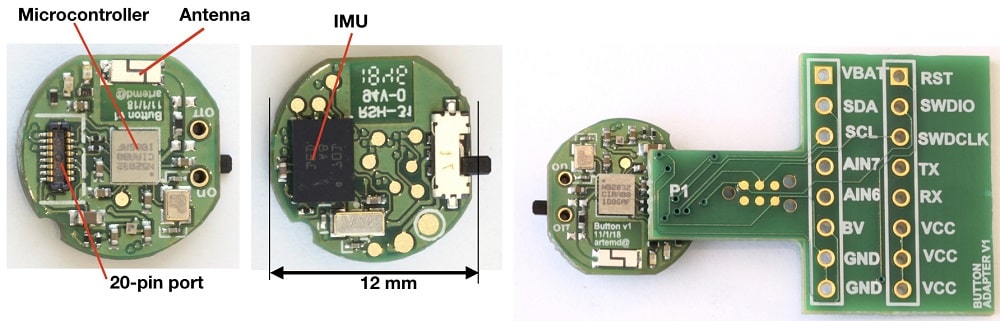

Using Nordic Semiconductor’s nRF52832 and ARM Cortex M4F, the circuit board has 2.4 GHz radio as well as Bluetooth Low Energy (BLE) for low power consumption. A 9-axis inertial measurement unit (IMU) by Bosch’s BNO055 gives onboard sensor functionalities. A 10mAh lithium polymer battery is enough to power the device for up to 4 hours. Reducing the touch sensitivity feature to one percent duty cycle significantly increases the battery life to a maximum of 15 hours. The circuit board also has a 20-pin connector for programming and charging of the microcontroller. All these advanced components have been embedded on a board having a diameter of just 12mm.

Mechanical arrangement

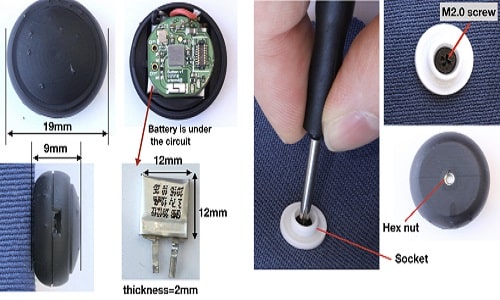

With the help of 3-D printing, the enclosure within the snap fastener has been custom-designed for electronics. The snap button is interfaced with a socket using an M2.0 hex nut and a 4mm long screw. The total weight of the entire snap fastener button is 2.4 grams (including the electronics).

Applications

Music Controller

SensorSnaps can be placed on the cufflinks of a shirt and connected to a music player of an Android phone. The in-built gyroscope detects the rotation angle and angular velocity while rotating the SensorSnap for increasing/decreasing the volume, fast-forwarding or rewinding the audio or simply play or pause the audio.

Body motion tracking

Instead of relying on cameras for capturing body motion, with the help of the 9-axis of IMU, tracking the movement of different body parts can now be easily achieved.

Assistive communication

The SensorSnaps can be efficiently used as an interface for Augmentative and Alternative communication by people having a motor impairment. By placing SensorSnaps anywhere on the clothing, for example on a shirt cuff, a simple movement of the forearm will enable the sensor to move the cursor or any pointing device on a computer screen.

Conclusion

Despite the challenges, it was shown that miniature electronics can be implemented into fabrics without any need to make them flexible. This innovation lays the foundation for making further improvements and implements it for wider use cases.