This technology could enhance the solar reactor’s energy efficiency, significantly improving the economic viability of sustainable aviation fuels.

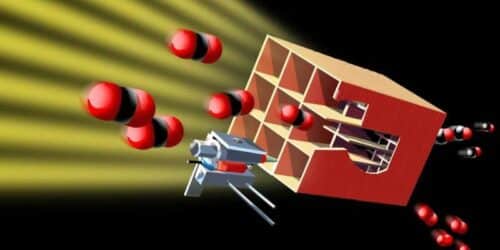

Engineers at ETH Zurich have been making strides in renewable energy. In 2019, they showcased the complete thermochemical process for generating liquid fuels from sunlight and air, and now, their latest innovation promises to revolutionise this technology further. At the core of this process is a solar reactor that harnesses concentrated sunlight, reaching temperatures of up to 1,500°C. Within this reactor, a thermochemical cycle ingeniously splits water and CO2 extracted from the atmosphere earlier, resulting in syngas – a blend of hydrogen and carbon monoxide. These syngas can be transformed into liquid hydrocarbon fuels like kerosene, powering the aviation industry while maintaining a carbon-neutral footprint. Previous attempts using structures with isotropic porosity posed limitations. These structures diminished solar radiation as it travelled into the reactor, restricting the internal temperature and fuel production.

Enter 3D printing methodology, developed by researchers from ETH Zurich’s André Studart and Aldo Steinfeld groups. This innovation enables the fabrication of ceramic structures with intricate pore geometries, ensuring more efficient transportation of solar radiation into the reactor’s core. Published in Advanced Materials Interfaces, their hierarchical designs incorporate channels and pores that broaden at the surface exposed to sunlight and gradually taper toward the reactor’s rear. This setup maximises the absorption of concentrated solar radiation across the entire structure, guaranteeing the entire porous framework reaches the crucial 1,500°C temperature, significantly boosting fuel production.

The manufacturing process relies on extrusion-based 3D printing and a specially formulated ink, possessing low viscosity and a high concentration of ceria particles. This unique ink maximises the presence of redox-active material. Initial testing has been promising. These hierarchical structures, when subjected to the same intense solar radiation (equivalent to 1,000 suns), produce twice as much fuel as their uniform counterparts. The potential here is undeniable. This development brings one step closer to harnessing the sun’s energy for sustainable fuel production, potentially reshaping the future of aviation and reducing our carbon footprint.